Mineral separation method for improving manganese grade in low-grade mixed manganese mine

A beneficiation method and low-grade technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of difficult monomer dissociation, difficulty in manganese beneficiation recovery, etc., to promote monomer dissociation, irradiation time Short, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

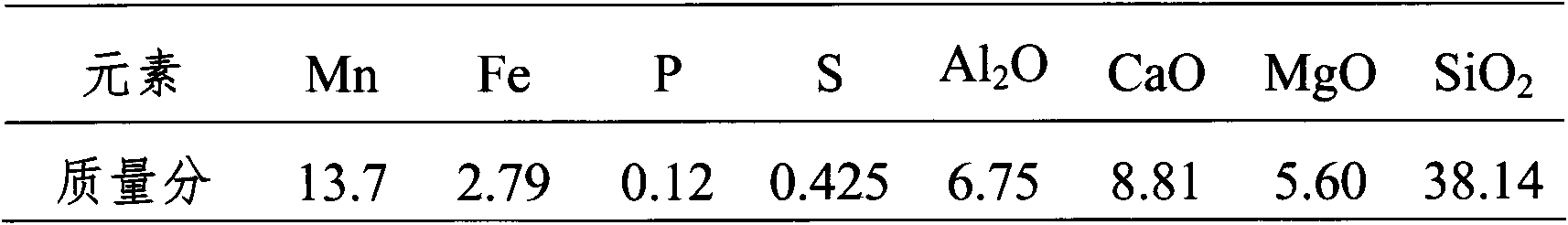

[0013] Example 1: The mixed manganese ore is taken from a mine in Guangxi. The multi-element analysis of the raw ore is shown in Table 1, and the phase analysis of the manganese minerals in the raw ore is shown in Table 2.

[0014] Table 1 Multi-element analysis of raw ore, %

[0015]

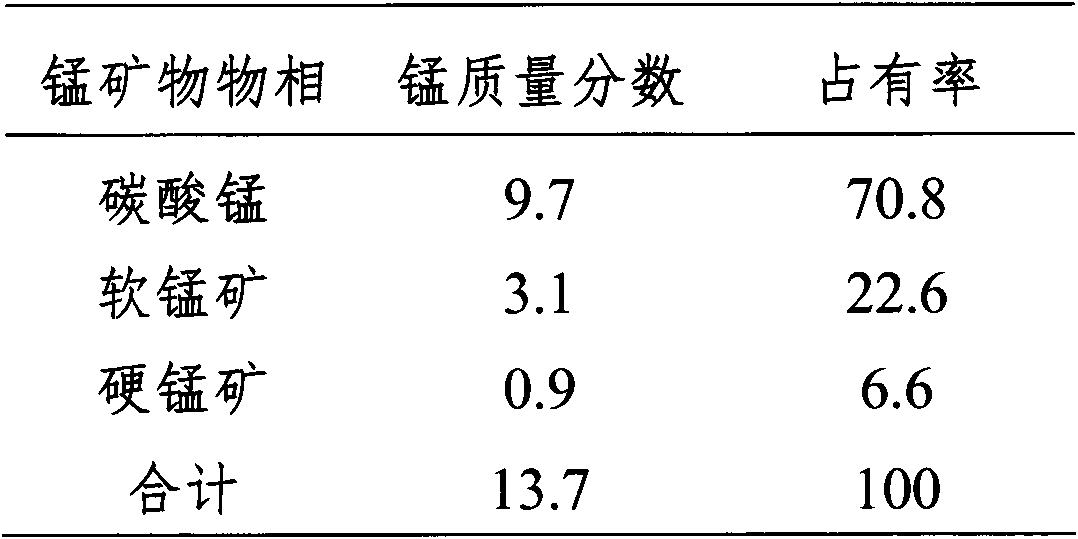

[0016] Table 2 Raw ore manganese mineral phase analysis, %

[0017]

[0018] Take 10kg of ore sample, crush and sieve to obtain ore powder with a particle size of less than 25mm, add 0.75kg of industrial coal powder with a particle size of less than 2mm, mix well and carry out microwave roasting at a roasting temperature of 650°C for a roasting time of 25 minutes; The product is transferred to cold water, and then wet-milled until the particle size is less than 0.1mm. When grinding, the pulp concentration is 70% solid mass fraction; after grinding, the pulp concentration is adjusted to 30% solid mass fraction. Strong magnetic separation is carried out on the machine to obtain magnetic se...

Embodiment 2

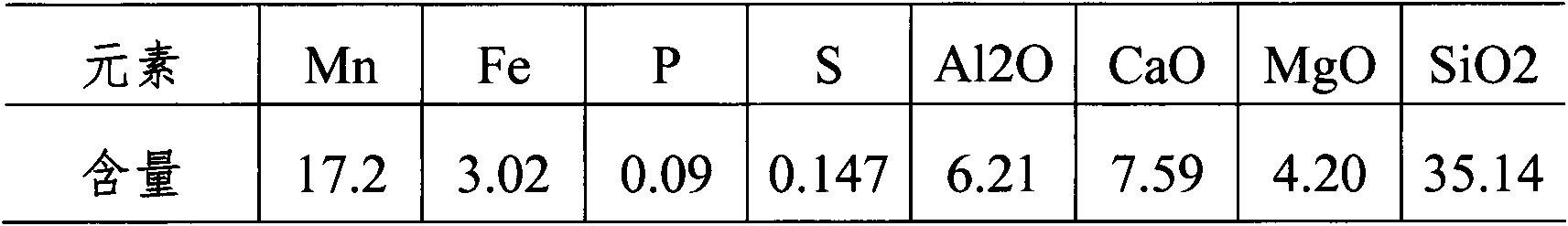

[0019] Example 2: The mixed manganese ore is taken from a mine in Hunan. The multi-element analysis of the raw ore is shown in Table 3, and the phase analysis of the manganese minerals in the raw ore is shown in Table 4.

[0020] Table 3 Raw ore multi-element analysis, %

[0021]

[0022] Table 4 Raw ore manganese mineral phase analysis, %

[0023]

[0024] Take 10kg of ore sample, crush and sieve to obtain ore powder with a particle size of less than 25mm, add 1.0kg of industrial coal powder with a particle size of less than 2mm, mix well and carry out microwave roasting at a roasting temperature of 600°C for a roasting time of 30 minutes; The product is transferred to cold water, and then wet-milled until the particle size is less than 0.1mm. The pulp concentration is 70% solid mass fraction during grinding; after grinding, the pulp concentration is adjusted to 25% solid mass fraction. Strong magnetic separation is carried out on the machine to obtain magnetic separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com