Device for centrifugally casting cylinder sleeve

A centrifugal casting and cylinder liner technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of material waste, high cost, low casting yield, etc., to achieve simple operation, improved qualification rate, protection Metal type effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

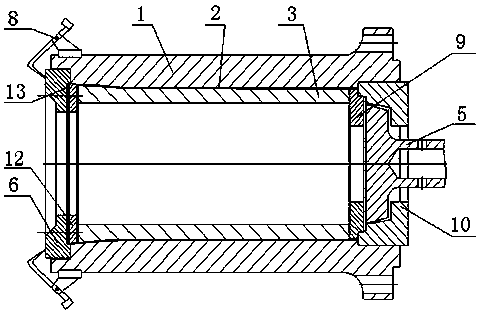

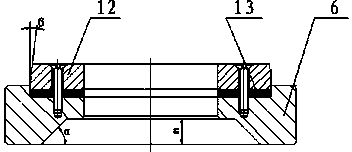

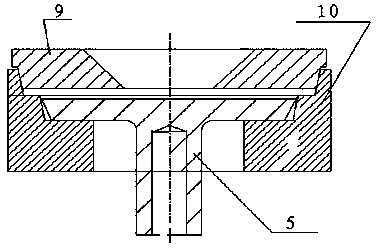

[0026] The model of the centrifugal casting cylinder liner includes a cylindrical mold 1, the inner hole of the mold 1 is a round hole with a certain taper, and the mold 1 is connected to the centrifugal casting machine by bolts. The inner hole of the mold 1 away from the front end of the centrifugal casting machine is a stepped hole II, and the inner hole of the mold 1 near the rear end of the centrifugal casting machine has a stepped hole I. In the inner hole of the rear end of the mold 1, a steel back pad iron 9 is set, and a back disc bushing 10 is set in the stepped hole I, and the back disc bushing 10 and the back pad iron 9 are matched by a conical surface, and the conical surface The taper is 10°. The outer diameter of the rear disc liner 10 is closely matched with the large hole at the outer end of the stepped hole I of the mould, and the diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com