Low grade fly ash mixed slurry used for concrete and preparation method thereof

A mixed slurry, low-grade technology, applied in the direction of solid waste removal, etc., can solve the problems of high cost of modifier and equipment, unsuitable for large-scale production of concrete, complicated production process, etc., to promote secondary hydration The effect of reaction, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

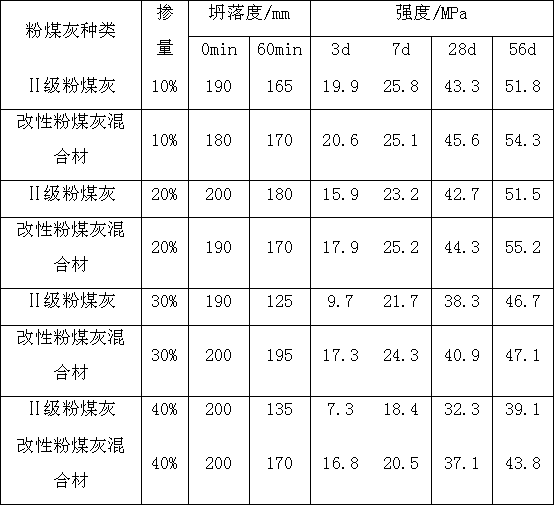

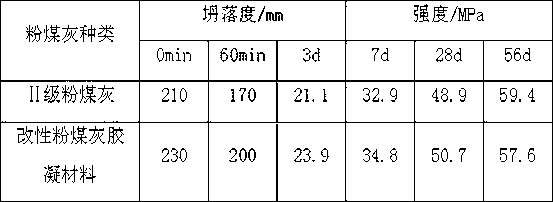

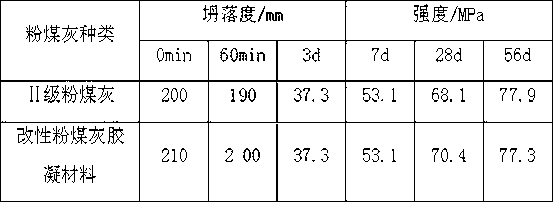

Embodiment 1

[0035] Step 1, raw material preparation: select low-grade fly ash, industrial waste residue, modifier and recycled water from the mixing station; according to the mass percentage of each component: low-grade fly ash solid content 52%, steel slag 10%, modified The agent is 2% gypsum, 1% triethanolamine and 35% recycled water from the mixing station. The recycled water from the mixing station contains the quality of water in low-grade fly ash.

[0036] The low-grade fly ash has a moisture content of 10%-25%, a sulfur trioxide content of ≤3%, a carbon content of ≤12%, and a sieve residue of 45 μm square hole ≤50%.

[0037] The industrial waste slag is steel slag or slag, with a sulfur trioxide content of ≤3%, a carbon content of ≤2%, and a sieve residue of 80 μm square hole sieves of ≤25%.

[0038] The mass percentages of the various components of the modifier are as follows: the reinforcement component accounts for 50%-80%, and the surface activation component accounts for 20%-5...

Embodiment 2

[0047]Step 1, raw material preparation: select low-grade fly ash, industrial waste residue, modifier and recycled water from the mixing station; the mass percentage of each component is: low-grade fly ash solid content 49%, slag 9%, modifier for Na 2 SO 4 2% and 1% of polycarboxylate polymer and 39% of the recycled water of the mixing station, the recycled water of the mixing station contains the quality of the water in the low-grade fly ash.

[0048] The low-grade fly ash has a moisture content of 10%-25%, a sulfur trioxide content of ≤3%, a carbon content of ≤12%, and a sieve residue of 45 μm square hole ≤50%.

[0049] The industrial waste slag is steel slag or slag, with a sulfur trioxide content of ≤3%, a carbon content of ≤2%, and a sieve residue of 80 μm square hole sieves of ≤25%.

[0050] The mass percentages of the various components of the modifier are as follows: the reinforcement component accounts for 50%-80%, and the surface activation component accounts for 20...

Embodiment 3

[0059] Step 1, raw material preparation: select low-grade fly ash, industrial waste residue, modifier and recycled water from the mixing station. The mass percentage of each component is: low-grade fly ash solid content 37%, slag 15%, Na 2 SiO 4 2% and 1% of triethanolamine, 45% of recycled water from the mixing station, and the recycled water from the mixing station contains the quality of low-grade fly ash reclaimed water.

[0060] The low-grade fly ash has a moisture content of 10%-25%, a sulfur trioxide content of ≤3%, a carbon content of ≤12%, and a sieve residue of 45 μm square hole ≤50%.

[0061] The industrial waste slag is steel slag or slag, with a sulfur trioxide content of ≤3%, a carbon content of ≤2%, and a sieve residue of 80 μm square hole sieves of ≤25%.

[0062] The mass percentages of the various components of the modifier are as follows: the reinforcement component accounts for 50%-80%, and the surface activation component accounts for 20%-50%.

[0063] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com