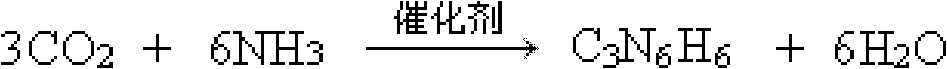

Method for synthesizing cyanic acid or melamine by utilizing ammonia gas and carbon dioxide

A technology of cyanuric acid and melamine, which is applied in the chemical industry, can solve the problems of high cost, complicated process, and high toxicity of raw materials, and achieve the effect of reducing production cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

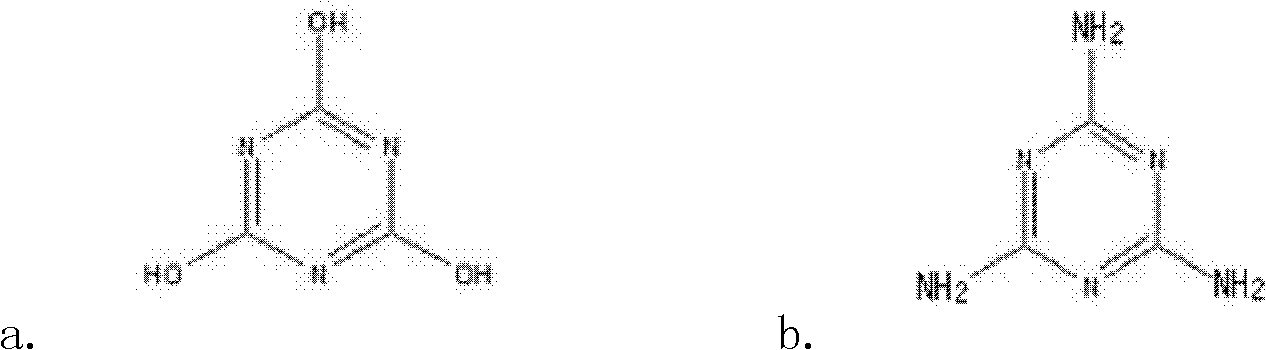

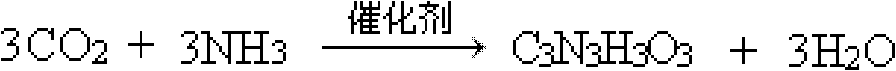

[0039] Embodiment 1. take ammonia, carbon dioxide as raw material synthetic cyanuric acid, reaction formula is:

[0040] 3CO 2 +3NH 3 →C 3 N 3 h 3 o 3 +3H 2 o

[0041] Press n(NH 3 ):n(CO 2 )=0.8: 1 molar ratio, feed ammonia 440g, carbon dioxide 1040g in reactor, at 240-250 ℃, keep system reaction pressure to be 20.0MPa, react 10min; Reaction product is mainly white cyanuric acid (C 3 N 6 h 3 o 3 ) solid, the content is 95%, the content after purification is 98%, and the yield is 95%;

Embodiment 2

[0042] Embodiment 2. take ammonium bicarbonate as raw material synthetic cyanuric acid, and reaction formula is:

[0043] 3NH 4 HCO 3 →C 3 N 3 h 3 o 3 +6H 2 o

[0044] Add 670g of ammonium bicarbonate in the reactor, keep the system reaction pressure at 20.0MPa at 230-250°C, and react for 5min; the reaction product is mainly white cyanuric acid (C 3 N 6 h 3 o 3 ) solid, the content is 95.2%, the content after purification is 98.5%, and the yield is 95%.

Embodiment 3

[0045] Embodiment 3. take ammonia and carbon dioxide as raw material to synthesize cyanuric acid under catalytic conditions, and the reaction formula is:

[0046]

[0047] Press n(NH 3 ):n(CO 2 )=1.1:1 reaction volume, add 440g of ammonia, 1040g of carbon dioxide and 50g of ammonium chloride in the reactor, heat to 200-210°C, keep the system reaction pressure at 15.0MPa, and react for 15min; the reaction product is mainly white three Polycyanic acid (C 3 N 6 h 3 o 3 ) solid, the content is 96%, the content after purification is 99%, and the yield is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com