Leaching method for associated copper, molybdenum and nickel in coal mine containing scherbinaite

A technology of associated metals and coal mines, which is applied to the improvement of process efficiency, flotation, solid separation, etc., can solve the problems of large waste of resources, environmental pollution, low vanadium leaching rate, etc., and achieve the effect of high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

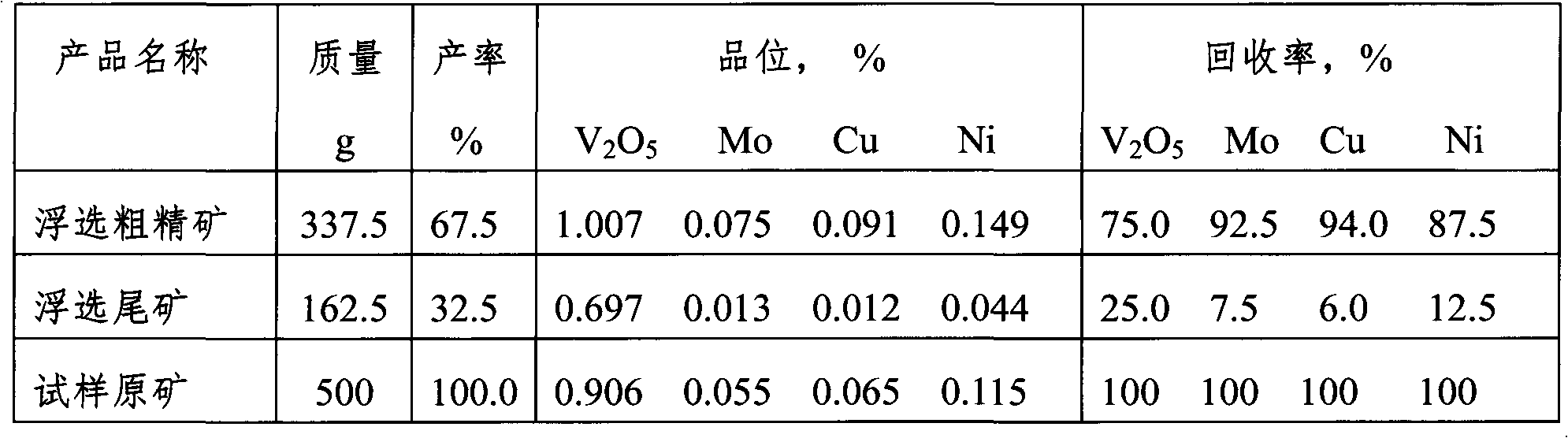

[0012] Example 1: The sample was taken from the stone coal ore of the No. 1 ore body of Shaba Pingshi Coal Mine, Olioyang County, Shaanxi Province. The multi-element analysis of the sample is shown in Table 1.

[0013] Table 1 sample multi-element analysis (%)

[0014] Element

V 2 o 5

Mo

Cu

Ni

Fe

Ca

Al

Si

Mg

K

S

0.906

0.055

0.065

0.115

5.53

6.04

6.23

23.74

2.39

2.36

0.56

[0015] Get sample 500g, carry out in the following steps to the leaching of vanadium in sample and associated metal molybdenum-copper-nickel:

[0016] (1) Crushing and grinding: the sample is crushed and wet-grinded until the particle size content of less than 0.074mm accounts for 80%, and the concentration of the grinding slurry is 70% of the solid mass fraction;

[0017] (2) pulping: after the grinding is completed, add water to adjust the pulp conce...

Embodiment 2

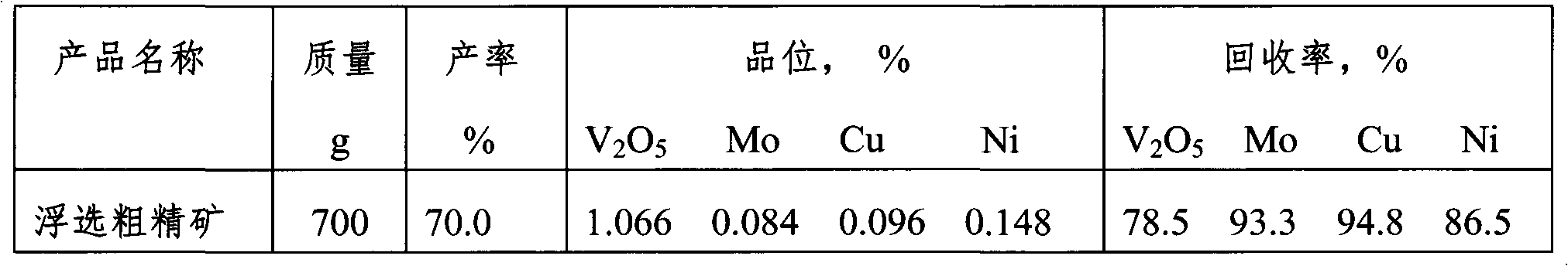

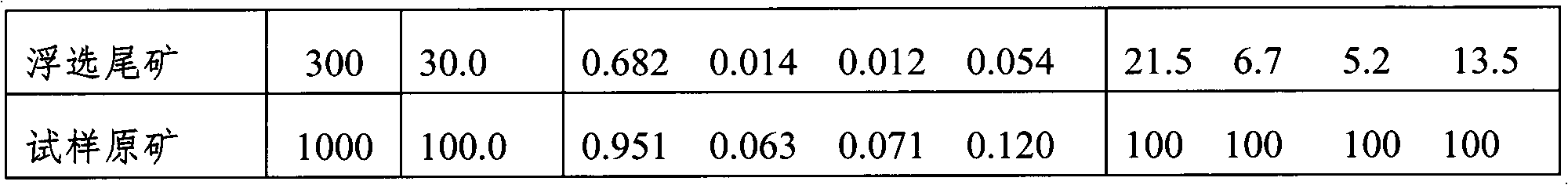

[0023] Example 2: The sample was taken from the stone coal mine of the No. II ore body of Shaba Pingshi Coal Mine, Olioyang County, Shaanxi Province. The multi-element analysis of the sample is shown in Table 3.

[0024] Table 3 sample multi-element analysis (%)

[0025] Element

V 2 o 5

Mo

Cu

Ni

Fe

Ca

Al

Si

Mg

K

S

0.951

0.063

0.071

0.120

5.72

6.51

6.18

22.55

2.58

2.076

0.74

[0026] Get sample 1000g, carry out in the following steps to the leaching of vanadium in sample and associated metal molybdenum-copper-nickel:

[0027] (1) Crushing and grinding: the sample is crushed and wet-grinded until the particle size content of less than 0.074mm accounts for 78.5%, and the concentration of the grinding slurry is 70% of the solid mass fraction;

[0028] (2) Slurry: after the grinding is completed, add water to adjust the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com