Method for preparing ferric manganese oxalate from high-iron manganese oxide ore

A technology of iron manganese oxalate and manganese oxide ore is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate and other directions, which can solve the problems of high cost and large pollutant discharge, achieve efficient leaching and reduce production costs , the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

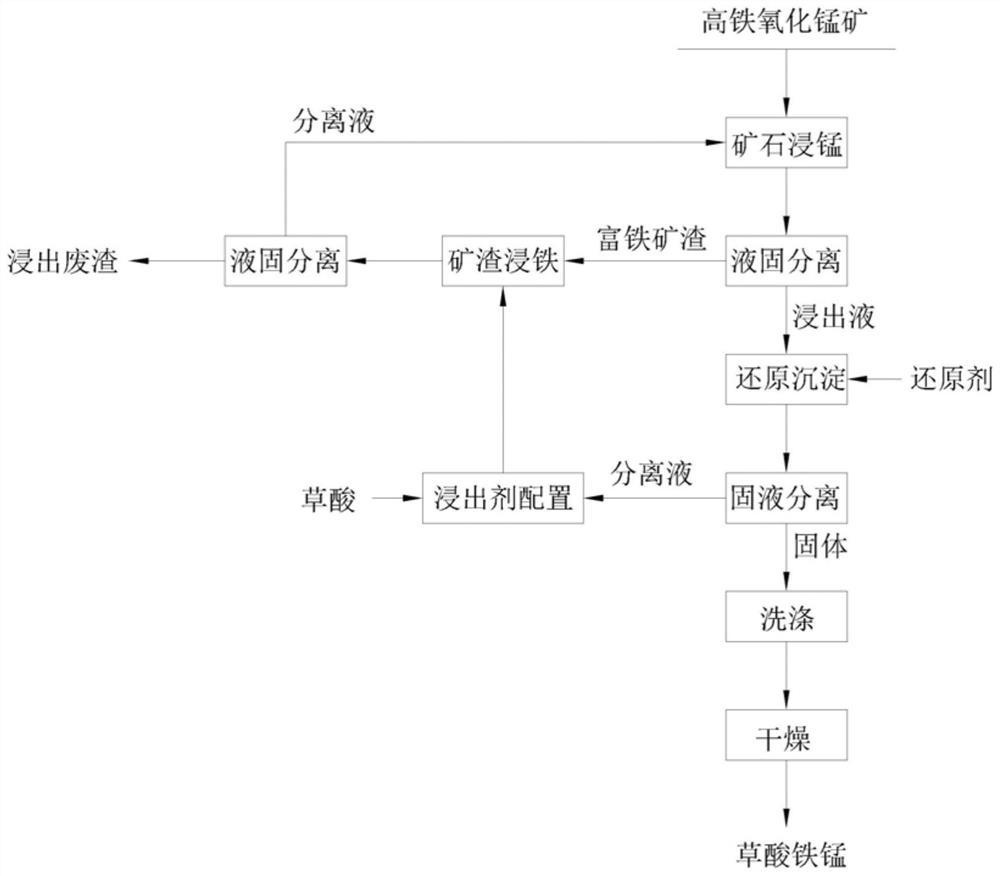

[0060] A method of utilizing high iron manganese oxide ore to prepare iron manganese oxalate, comprising the following steps:

[0061] (1) Manganese leaching from ore: use oxalic acid / ferric oxalate mixed solution as leaching agent to mix slurry with high iron manganese oxide ore, and the slurry-to-solid ratio (volume-to-mass ratio) is 5:1. The reaction time is 1h, so that the manganese in the high iron manganese oxide ore is converted into soluble manganese ions;

[0062] (2) liquid-solid separation: the slurry obtained in step (1) is subjected to pressure filtration separation to obtain iron-containing slag and separation liquid one containing oxalate, ferric iron and manganese ions;

[0063] (3) reduction of heavy iron and manganese: ultraviolet radiation is carried out in the separation liquid one obtained in step (2), so that ferric ions are reduced to divalent iron ions to obtain iron manganese oxalate precipitation; and centrifugal separation is carried out to obtain ir...

Embodiment 2

[0071] A method of utilizing high iron manganese oxide ore to prepare iron manganese oxalate, comprising the following steps:

[0072] (1) Manganese leaching from ore: use oxalic acid / ferric oxalate mixed solution as a leaching agent to prepare slurry with high iron manganese oxide ore, and the slurry-to-solid ratio (volume-to-mass ratio) is 8:1. The reaction time is 0.5h, so that the manganese in the high iron manganese oxide ore is converted into soluble manganese ions;

[0073] (2) liquid-solid separation: the slurry obtained in step (1) is subjected to pressure filtration separation to obtain iron-containing slag and separation liquid one containing oxalate, ferric iron and manganese ions;

[0074] (3) reduction of heavy iron and manganese: adding ascorbic acid to the separation liquid one obtained in step (2), reducing ferric ions to divalent iron ions to obtain iron manganese oxalate precipitation; and centrifugal separation to obtain iron manganese oxalate precipitation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com