A method for recovering platinum group metals from spent auto catalysts

An auto catalyst, platinum group metal technology, applied in the direction of improving process efficiency, can solve the problems of complex platinum group metal refining process, immature large-scale application, high equipment requirements, and achieve easy industrial implementation, high total recovery rate, The effect of increasing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

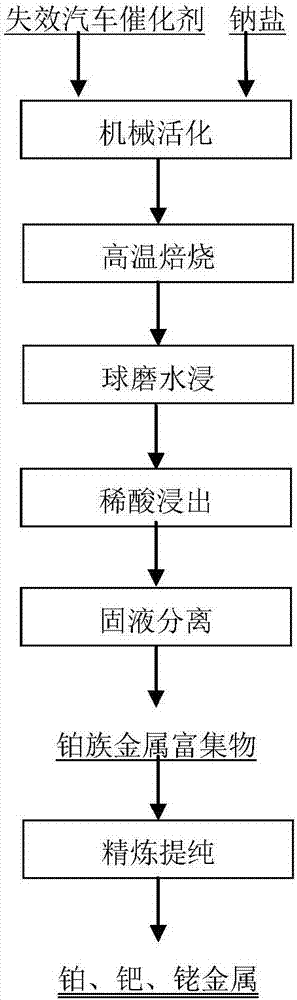

[0016] Embodiment 1, see attached figure 1 , take 500g of expired auto catalyst broken into 1mm (wherein SiO 2 About 40%, Al 2 o 3 About 35%, MgO about 10%, Pt 357g / t, Pd 963g / t, Rh 193g / t), mixed with 1kg sodium carbonate and 30g sodium borate, placed in a stirring mill for mechanical activation for 30min; the activated mixed material Place in an iron crucible and roast at 1300°C for 3 hours; place the roasted product in a wet ball mill for ball mill water immersion (conditions: pulp concentration 20%, initial water temperature 90°C, time 1h), after solid-liquid separation, hot water Washing; then the water-insoluble slag is leached with dilute acid (conditions: sulfuric acid mass concentration is 25%, room temperature, leaching time 2h, liquid-solid ratio 8), after solid-liquid separation, the platinum group metal enrichment is obtained, which is used Platinum group metals are dissolved, separated and purified to obtain platinum, palladium and rhodium metal products, and...

Embodiment 2

[0017] Embodiment 2, see attached figure 1 , take 500g of expired auto catalyst broken into 1mm (wherein SiO 2 About 40%, Al 2 o 3 About 35%, MgO about 10%, Pt 357g / t, Pd 963g / t, Rh 193g / t), mixed with 1kg sodium carbonate and 50g sodium borate, placed in a stirring mill for mechanical activation for 30min; the activated mixed material Place in an iron crucible and roast at 1250°C for 3 hours; place the roasted product in a wet ball mill for ball mill water immersion (conditions: pulp concentration 15%, initial water temperature 90°C, time 1h), after solid-liquid separation, hot water Washing; then the water-insoluble slag is leached with dilute acid (conditions: the mass concentration of sulfuric acid is 25%, room temperature, leaching time 2h, liquid-solid ratio 6), after solid-liquid separation, the platinum group metal enrichment is obtained, which is used in the present Platinum group metals are dissolved, separated and purified to obtain platinum, palladium and rhodi...

Embodiment 3

[0018] Embodiment 3, see attached figure 1 , take 500g of spent auto catalyst finely ground to 100 mesh (wherein SiO 2 About 40%, Al 2 o 3 About 35%, MgO about 10%, Pt 357g / t, Pd 963g / t, Rh 193g / t), mixed with 1.5kg sodium carbonate and 50g sodium borate, placed in a stirring mill for mechanical activation for 30min; the activated mixture The material was placed in an iron crucible and roasted at 1200°C for 3 hours; the roasted product was placed in a wet ball mill for ball milling and water immersion (conditions: pulp concentration 20%, initial water temperature 90°C, time 0.5h), after solid-liquid separation, Washing with hot water; then leaching the water-insoluble slag with dilute acid (conditions: sulfuric acid mass concentration is 20%, room temperature, leaching time 3h, liquid-solid ratio 8), after solid-liquid separation, the platinum group metal enrichment is obtained, and its The existing platinum group metal dissolution, separation and purification process is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com