Method for determining optimal doping ratio of nonlinear gallium selenide crystal

A gallium selenide, nonlinear technology, applied in the field of technical physics, can solve the problem of low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

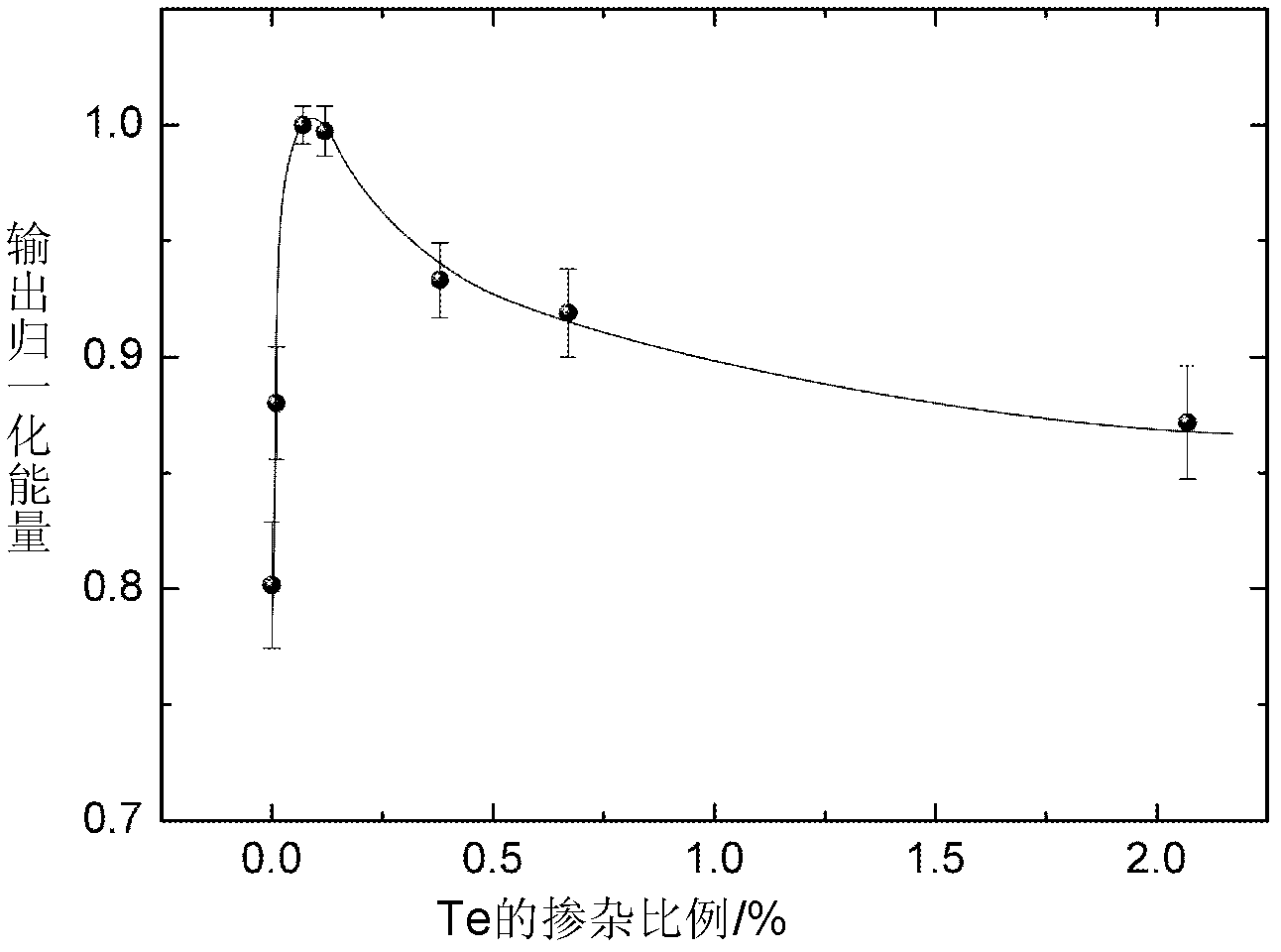

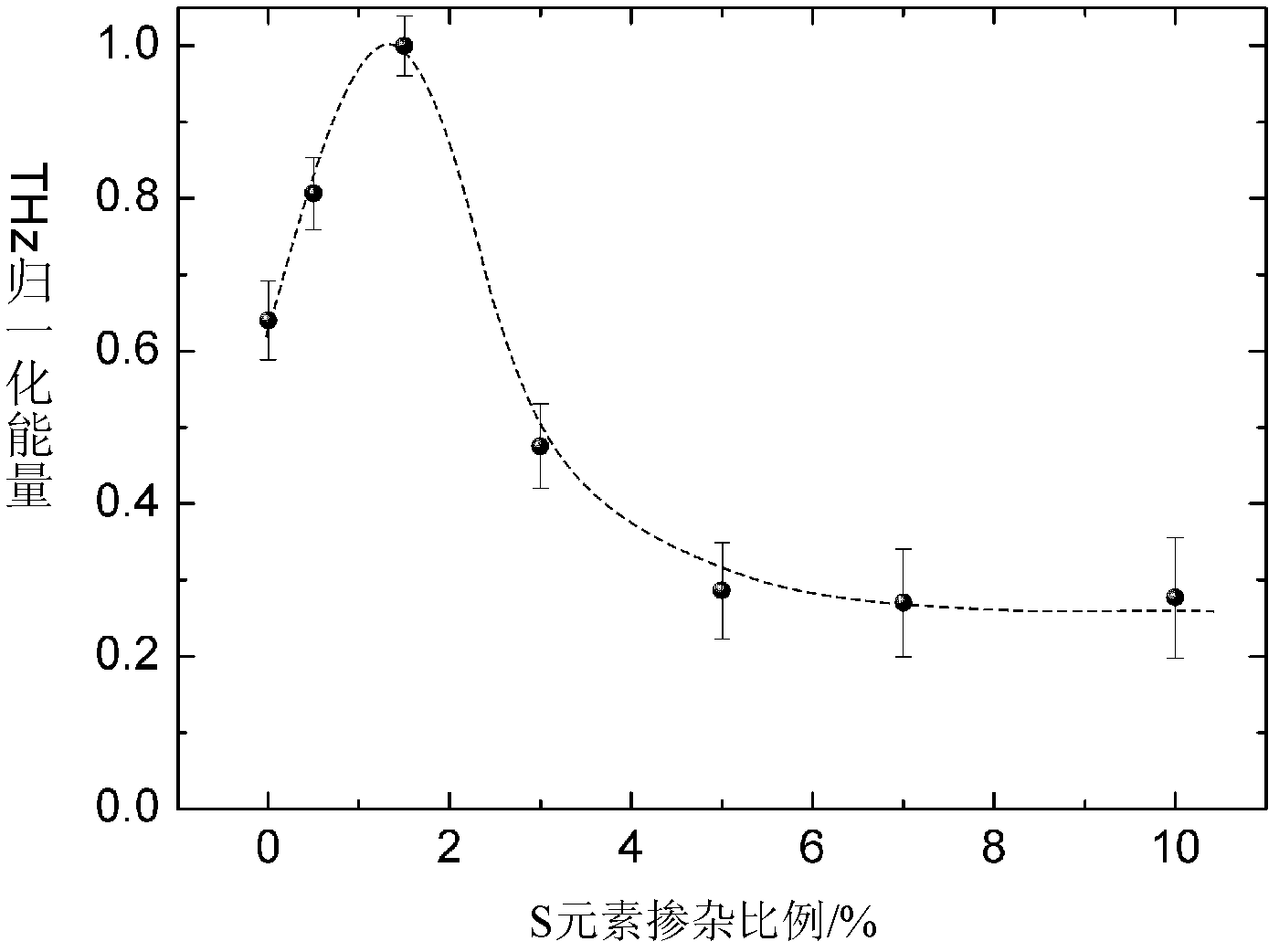

[0031] 1. Doping 0.05%, 0.1%, 0.5% and 1% Te, and 0.5%, 1%, 2%, 3%, 5%, 7%, and 10% S in the GaSe crystal respectively, and the doped GaSe crystal rods, pure GaSe or doped GaSe crystals are grown in a rotating thermal field to obtain single crystals, the vertical temperature gradient of the crystal plane is 10°C / cm, and the crystal growth rate is 10mm / day;

[0032] 2. Use an electron probe microanalyzer to measure the actual doping ratio of the single crystal obtained in step 1. Through the test, the doping ratio of the crystal sample is as follows: S element 0.45%, 0.92%, 1.95%, 2.96%, 4.96% , 6.97%, 10%; Te element: 0.01%, 0.07%, 0.38%, 0.67%;

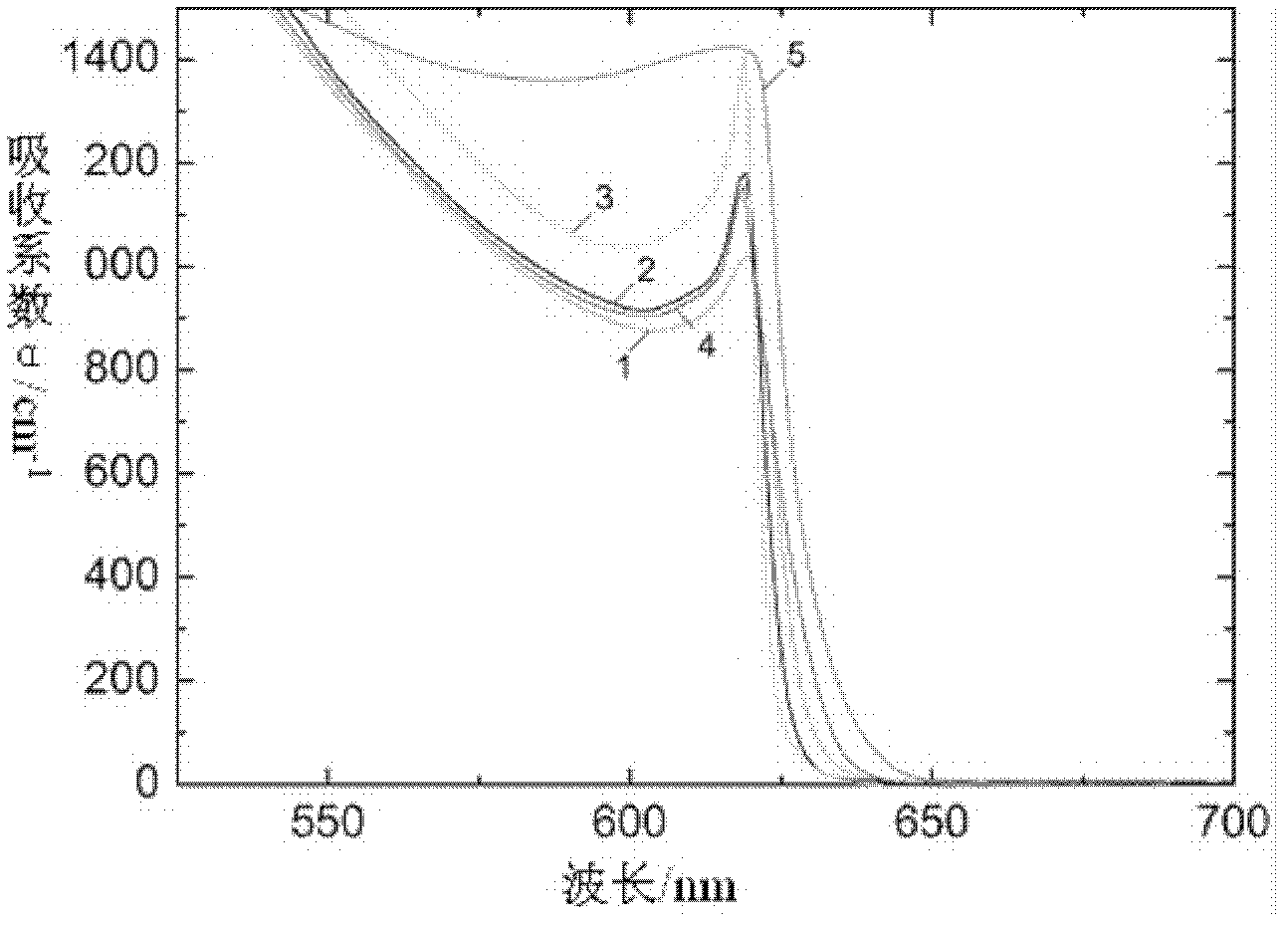

[0033] 3. Use a scanning spectrophotometer to measure the excitonic absorption line of the crystal obtained in step 1. The model is Cary-100, produced by Varian, Australia: the wavelength range is between 190-900nm, the spectral resolution is 0.2-4nm, and the wavelength deviation ± 1nm;

[0034] 4. According to the absorption coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com