Preparation method and application of nitrogen-doped graphene oxide film

A graphene film, graphene film technology, applied in the field of electrochemistry, can solve the problems of short service life, easy corrosion or dissolution, weak stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

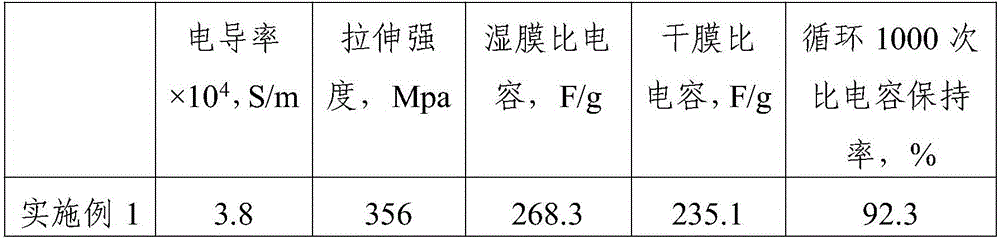

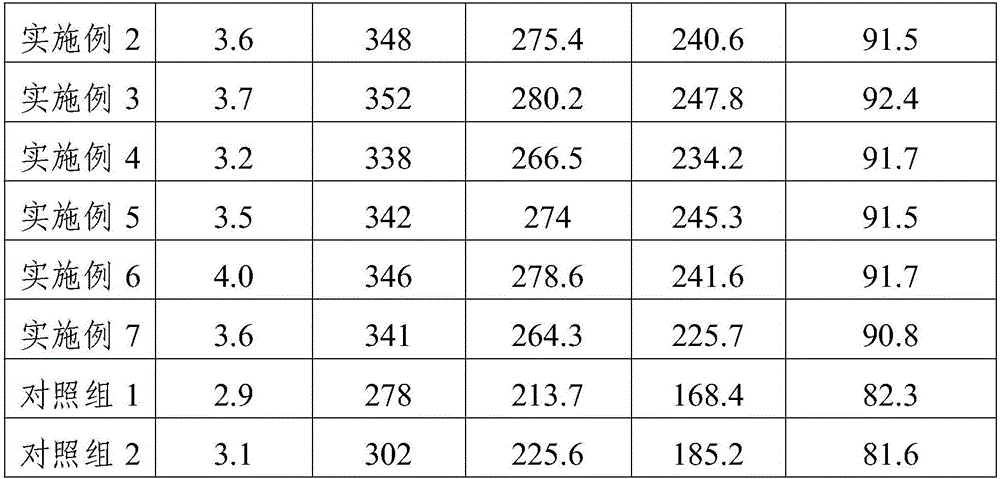

Examples

Embodiment 1

[0020] A method for preparing a nitrogen-doped graphene oxide film, comprising the following steps:

[0021] 1) Preparation of graphene oxide film

[0022] Vacuum filter the graphene oxide suspension through a microporous membrane to obtain a filter cake attached to the microporous membrane, soak the filter cake attached to the microporous membrane in an aqueous cross-linking agent solution for 12 minutes, take it out, and peel off the micropore The filter membrane is dried in a vacuum drying oven, and the graphene oxide membrane is obtained after drying;

[0023] 2) Graphene oxide membrane treatment

[0024] Place the graphene oxide film prepared in step 1) in a mixed solution of polyvinyl alcohol and polyaniline, adjust the temperature to 58° C., soak for 20 minutes, and then place it in a vacuum drying oven to dry to obtain the treated graphene oxide film ;

[0025] 3) Graphene oxide film doped with nitrogen

[0026] Add the ammonia source and the graphene oxide film pr...

Embodiment 2

[0029] A method for preparing a nitrogen-doped graphene oxide film, comprising the following steps:

[0030] 1) Preparation of graphene oxide film

[0031] Vacuum filter the graphene oxide suspension through a microporous membrane to obtain a filter cake attached to the microporous membrane, soak the filter cake attached to the microporous membrane in an aqueous cross-linking agent solution for 14 minutes, take it out, and peel off the micropore The filter membrane is dried in a vacuum drying oven, and the graphene oxide membrane is obtained after drying;

[0032] 2) Graphene oxide membrane treatment

[0033] Place the graphene oxide film prepared in step 1) in a mixture of polyvinyl alcohol and polyaniline, adjust the temperature to 52°C, soak for 20 minutes, and then place it in a vacuum drying oven to dry to obtain the treated graphene oxide film ;

[0034] 3) Graphene oxide film doped with nitrogen

[0035] Add the ammonia source and the graphene oxide film prepared in...

Embodiment 3

[0038] A method for preparing a nitrogen-doped graphene oxide film, comprising the following steps:

[0039] 1) Preparation of graphene oxide film

[0040] Vacuum filter the graphene oxide suspension through a microporous membrane to obtain a filter cake attached to the microporous membrane, soak the filter cake attached to the microporous membrane in an aqueous solution of a cross-linking agent for 15 minutes, take it out, and peel off the micropore The filter membrane is dried in a vacuum drying oven, and the graphene oxide membrane is obtained after drying;

[0041] 2) Graphene oxide membrane treatment

[0042] Place the graphene oxide film prepared in step 1) in a mixed solution of polyvinyl alcohol and polyaniline, adjust the temperature to 60°C, soak for 20 minutes, and then place it in a vacuum drying oven to dry to obtain the treated graphene oxide film ;

[0043] 3) Graphene oxide film doped with nitrogen

[0044] Add the ammonia source and the graphene oxide film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com