Acid and alkali neutralization granulating method of effervescent

An effervescent, acid-base technology, applied in pharmaceutical formulations, bulk delivery, drug delivery, etc., can solve the problems of complex production process, low production efficiency, and high production cost, and achieve simplified process, improved production efficiency, and acidity difference. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: paracetamol effervescent tablet

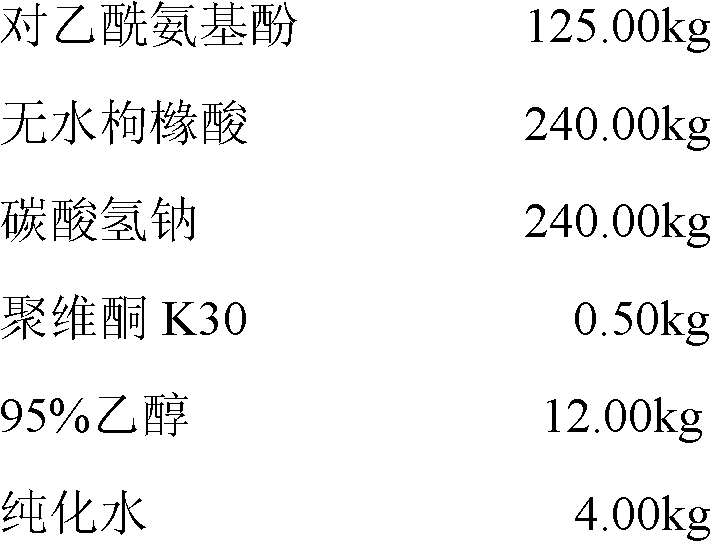

[0044] Granulation part:

[0045]

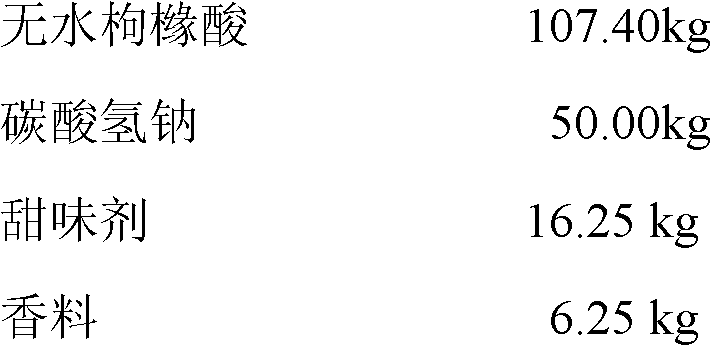

[0046] Mixing part:

[0047]

[0048] Production steps:

[0049] 1. Add acetaminophen, anhydrous citric acid, and sodium bicarbonate to the granulation kettle, stir and mix for 10 minutes at a stirring speed of 60 rpm;

[0050] 2. Weigh the povidone K30 in the granulation agent and put it in the liquid preparation tank, mix 95% ethanol and purified water to make the granulation agent and pour it into the spray tank, and spray the liquid into the stirring state in the kettle at a uniform speed In the material, the spraying flow rate is 1.2L / min. After the liquid is sprayed, the speed of the stirring paddle is 80rpm, stirring for 5 minutes, and at the same time, the cross cutter device is turned on for cutting and stirring. To form relatively uniform particles, the operating room temperature is 18°C and the relative humidity is less than 30%;

[0051] 3. Start the vacuum and st...

Embodiment 2

[0053] Embodiment 2: carbocisteine effervescent tablet

[0054] Granulation part:

[0055]

[0056]

[0057] Mixing part:

[0058] Sweetener 6.00kg

[0059] Spice 3.00kg

[0060] Production steps:

[0061] 1. Add anhydrous sodium citrate, anhydrous citric acid, sodium bicarbonate, and carbocisteine to the granulation kettle, stir and mix for 10 minutes at a stirring speed of 60 rpm;

[0062] 2. Weigh the povidone K30 in the granulation agent and put it in the liquid preparation tank, mix 95% ethanol and purified water to make the granulation agent and pour it into the spray tank, and spray the liquid into the stirring state in the kettle at a uniform speed In the material, the spray flow rate is 1.0L / min. After the liquid is sprayed, the speed of the stirring paddle is 70rpm, and the stirring is carried out for 4 minutes. At the same time, the cross cutter device is turned on for cutting and stirring. To form relatively uniform particles, the operating room temp...

Embodiment 3

[0065] Embodiment 3: zinc gluconate effervescent tablet

[0066] Granulation part:

[0067]

[0068] Mixing part:

[0069] Sweetener 14.00kg

[0070] Spice 4.00kg

[0071] Production steps:

[0072] 1. Add anhydrous citric acid, sodium bicarbonate, anhydrous sodium citrate, and zinc gluconate into the granulation kettle, stir and mix for 9 minutes at a stirring speed of 70 rpm.

[0073] 2. Mix and dissolve povidone K30 and 95% ethanol to make a granulation agent and pour it into the spray tank, and spray the liquid into the stirred material in the tank at a uniform speed. The spray flow rate is 1.1L / min. After spraying, the speed of the stirring paddle is 60rpm, stirring for 3 minutes, and at the same time, the cross cutter device is turned on for cutting and stirring, and the cutter speed is set at 800 rpm. After cutting, more uniform particles are formed. The temperature of the operating room is 26°C , the relative humidity is less than 30%;

[0074] 3. Start the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com