In-situ remediation method of heavy metal polluted site

An in-situ repair and heavy metal technology, applied in the restoration of contaminated soil, etc., can solve the problems of soft foundation, secondary pollution, etc., and achieve the effect of low equipment investment and operation costs, simple process, and unlimited treatment site location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

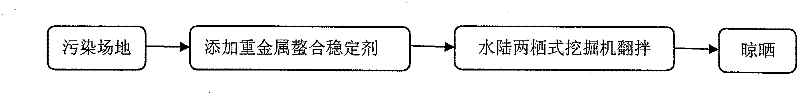

Method used

Image

Examples

Embodiment 1

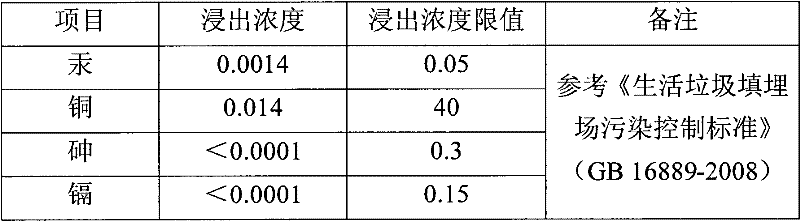

[0011] Example 1: Amphibious excavators were used to treat sites polluted by heavy metals such as mercury, copper, and cadmium in the Hangu sewage reservoir (heavy metal contents in the polluted sites are shown in Table 1). ① First, carry out the construction of the cofferdam to ensure that the transportation vehicles pass through during the construction period. ② Discharge the sewage in the cofferdam area. ③Wait for the pre-consolidation of the bottom mud, and dry the bottom mud in the air for 12 hours. If time is urgent, you can spray lime powder on the contaminated site to evenly accelerate the consolidation of the site. The thickness of the lime powder coverage is controlled at 2-5cm. ④ Begin to evenly apply heavy metal chelating and stabilizing agents on the surface of the polluted site. The amount of agents added is 10% (based on dry basis sludge, weight ratio), and the excavator is used for stirring, and the stirring is carried out in 3 times. Control the increment of ...

Embodiment 2

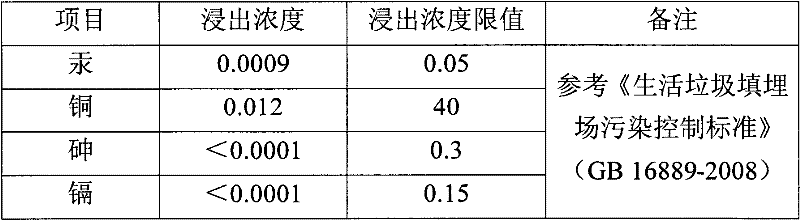

[0016] Embodiment 2: The implementation method is the same as in Embodiment 1, and the content of heavy metals in the polluted site is changed, as shown in Table 3. The application amount of the heavy metal chelating stabilizer was changed to 15% (based on dry sludge, weight ratio). After 2 to 3 months, measure the leaching concentration of heavy metals such as mercury, cadmium and copper to the polluted soil according to the requirements of "Pollution Control Standards for Domestic Garbage Landfill Sites" (GB 16889-2008), as shown in Table 4, all lower than The leaching concentration limit of heavy metals stipulated in this standard. Refer to "Sludge Disposal of Urban Sewage Treatment Plants for Land Improvement of Mud Quality" (CJ / T291), that is, the treated sites polluted by heavy metals such as mercury, copper, and cadmium can be used for land use.

[0017] Table 3 Heavy metal content in polluted sites Unit: mg / kg

[0018] project

content

project

c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com