Control system for loading and unloading manipulator of press

A control system and manipulator technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high development difficulty, poor operational flexibility and versatility, and high use costs, and achieve stable and reliable control response, low program maintenance costs, and set up use. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

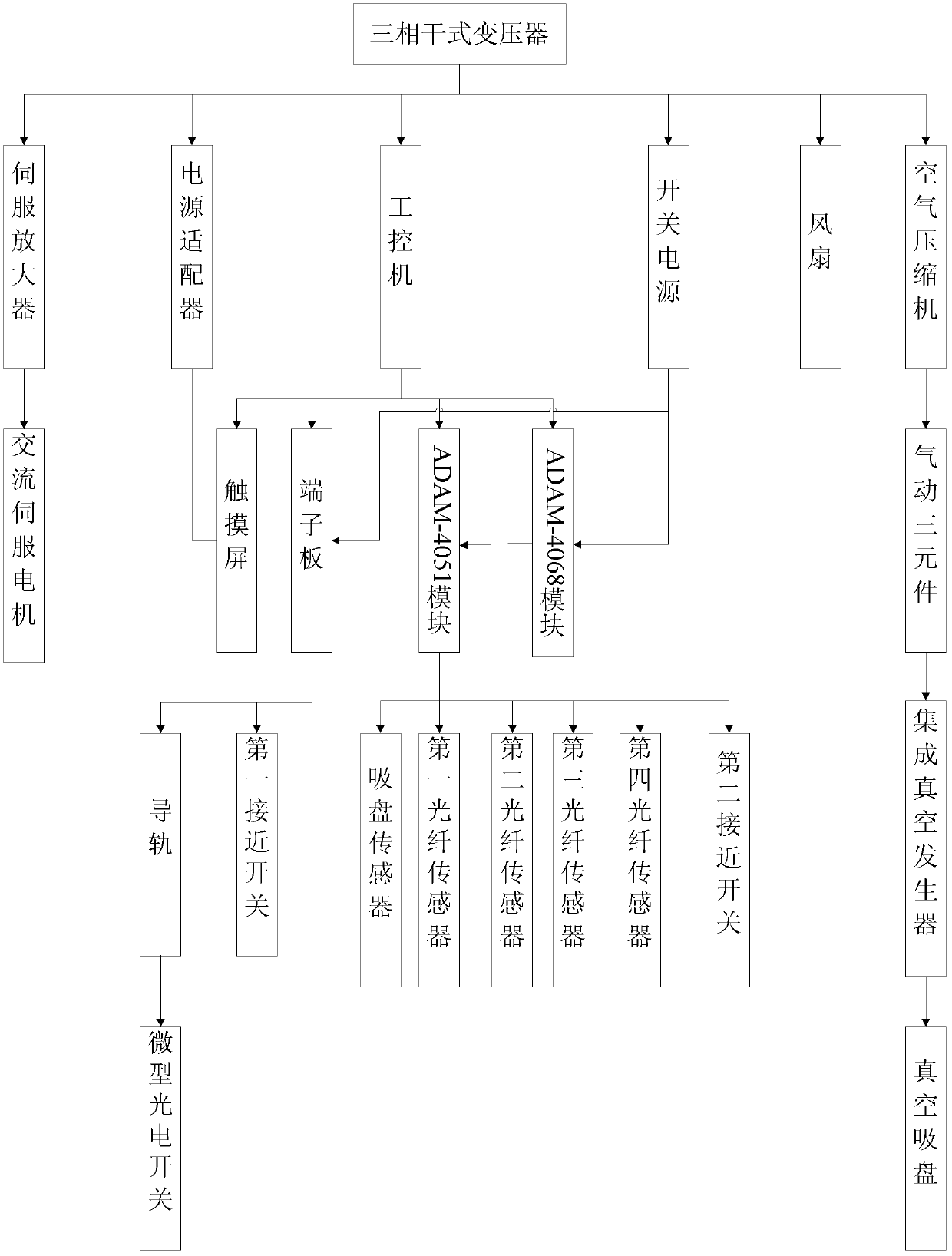

[0032] Such as figure 1 As shown, the control system of the loading and unloading manipulator of the press is characterized in that it includes a three-phase dry-type transformer, a servo amplifier, a power adapter, an industrial computer, a switching power supply, an air compressor, an AC servo motor, a terminal board, a data transmission module, and a pneumatic three-phase Components, rails, first proximity switch, second proximity switch, suction cup sensor, first fiber optic sensor, second fiber optic sensor, third fiber optic sensor, fourth fiber optic sensor, proximity switch, integrated vacuum generator, miniature photoelectric switch, vacuum sucker.

[0033] The three-phase dry-type transformer is respectively connected to the servo amplifier, power adapter, industrial computer, switching power supply, and air compressor; the servo amplifier is connected to the AC servo motor; the power adapter is connected to the terminal board, and the terminal board is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com