Sewage treatment system and sewage treatment method of anaerobic fluidized bed-micro aerobic membrane bioreactor

A membrane bioreactor and sewage treatment system technology, applied in the field of sewage treatment system, can solve the problems of high energy consumption and large floor space, and achieve the effects of low energy consumption, small floor space and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

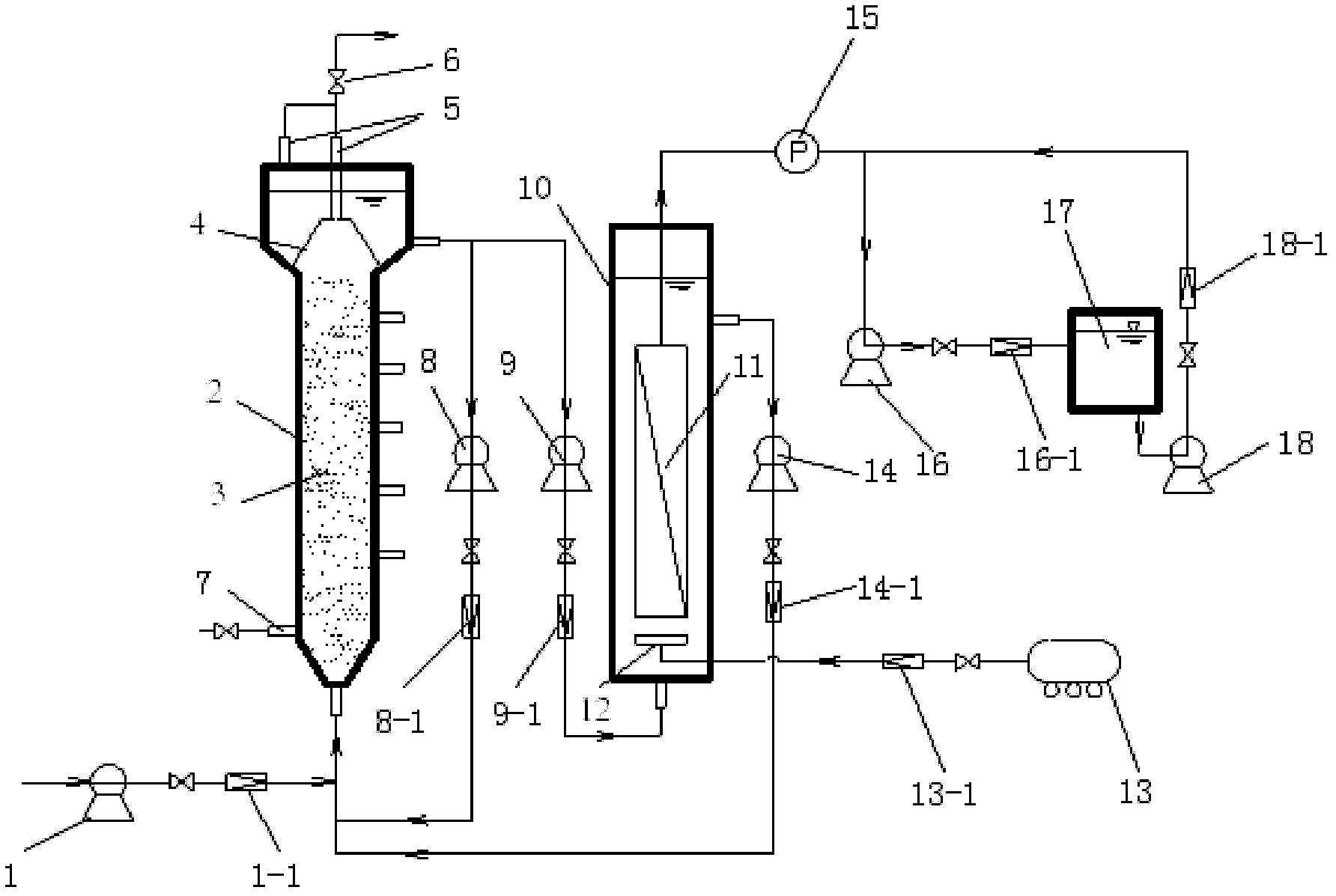

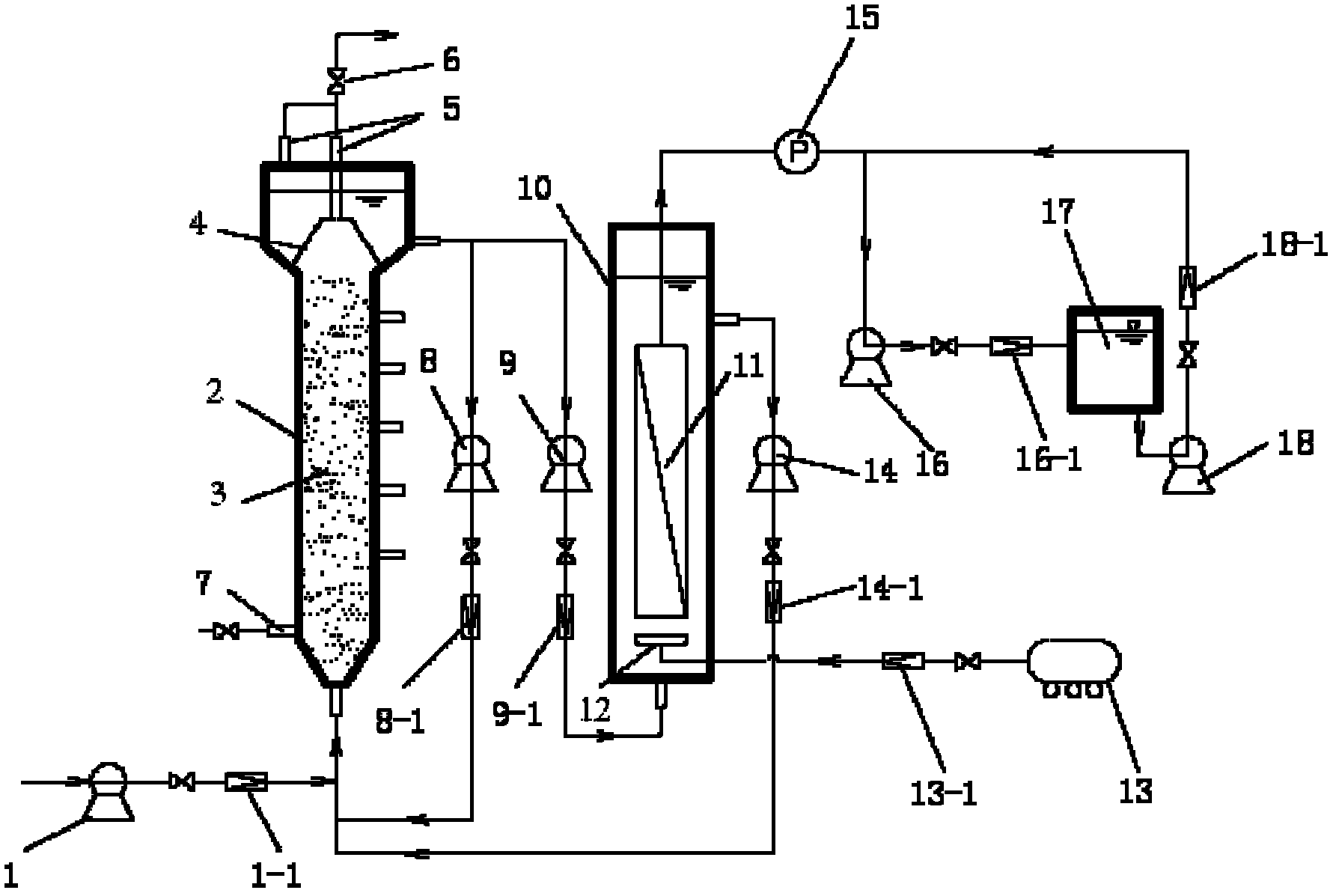

[0015] Specific embodiment one: the sewage treatment system of the anaerobic fluidized bed-microaerobic membrane bioreactor in the present embodiment, it is made up of anaerobic fluidized bed and microaerobic membrane bioreactor connected in series, includes sewage into Water pump 1, anaerobic fluidized bed 2, zeolite carrier 3, three-phase separator 4, gas collection system 5, exhaust valve 6, sludge discharge system 7, return pump 8, water inlet pump 9, membrane bioreactor 10, membrane Component 11, aeration system 12, blower 13, effluent suction pump 16 and clear water tank 17; zeolite carrier 3 fills the middle and lower parts of anaerobic fluidized bed 2, and three-phase separator 4 is arranged above zeolite carrier 3, The collection end of the gas collection system 5 is connected to the gas output end of the three-phase separator 4, the exhaust end of the gas collection system 5 is connected to the upper top of the anaerobic fluidized bed 2, the outlet of the sewage inlet...

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the system also includes a backwash pump 18, a sewage return pump 14 and a vacuum pressure gauge 15, and the inlet of the backwash pump 18 is communicated with the clear water pool 17. The outlet of the flushing pump 18 penetrates the upper part of the membrane bioreactor 10 and communicates with the cavity of the membrane module 11, and the water outlet on the upper side of the membrane bioreactor 10 communicates with the inlet at the bottom of the anaerobic fluidized bed 2 through the sewage return pump 14 ; The vacuum pressure gauge 15 is set on the water outlet of the membrane module 11 . Other structures and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the zeolite carrier 3 inside the anaerobic fluidized bed 2 is zeolite with a particle size of 0.5-1mm, and the activated sludge microorganisms are adsorbed on the surface of the zeolite. Finally, a biofilm will be formed on its surface, and the diameter of the entire particle is 2 to 3 mm. Other structures and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com