Multi-section plate membrane sludge concentration process method

A technology of sludge concentration and process method, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of anaerobic phosphorus release, high pollutants that need to be reprocessed, easy sludge floating, etc., and achieve the reduction of floor space , delayed membrane fouling, easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

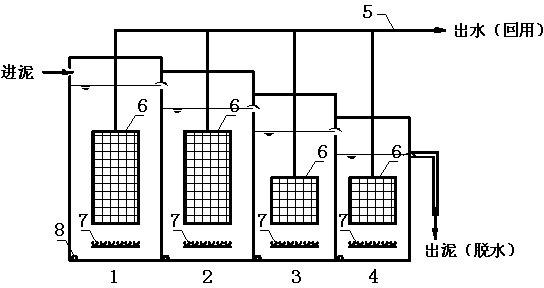

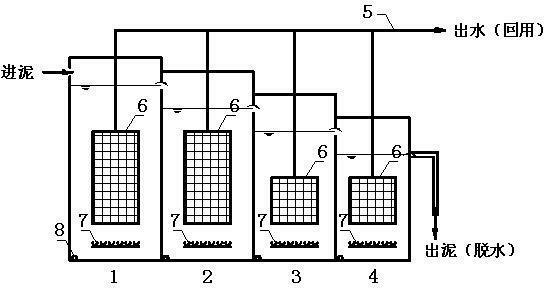

[0022] Example 1: figure 1 It is a schematic diagram of an embodiment of the present invention, and only takes four sections in series as an example, and does not limit the present invention.

[0023] The process of the present invention is set by the first reactor 1, the second reactor 2, the third reactor 3, and the fourth reactor 4 according to the push-flow operation mode of the liquid level difference, and the membrane water outlet system 5 and the flat plate are arranged in the above reactors. Membrane module 6 and aeration device 7, and a vent pipe 8 is set at the bottom of the reactor.

[0024] First of all, after the sludge enters the first reactor 1, the water in the sludge is separated by the membrane module 6, and is extracted out of the reactor by the membrane water outlet system 5, and the sludge is concentrated. At this time, due to the relatively high sludge concentration Low, the membrane effluent system 5 adopts a relatively large operating flux, and the aer...

Embodiment 2

[0029] The flat-panel membrane modules use PVDF and PAN, with a pore size of 0.2 μm. They are used to treat low-concentration residual activated sludge and are divided into four sections. The first reactor uses PAN flat-panel membrane modules, and the last three reactors use PVDF flat-panel membrane modules. 58 flat-plate membrane modules with a total membrane area of 42.34 m 2 . The membrane area of the first reactor is 11.68 m 2 , the membrane areas of the second, third and fourth reactors are all 10.22 m 2 . The amount of mud entering is 7.8 m 3 / d, the hydraulic retention time is 6.8 h, the sludge concentration is about 3.4 g / L, and the operating flux of the first reactor is 16 L / (m 2 h), the operating flux of the second reactor is 9 L / (m 2 h), the operating flux of the third reactor is 5 L / (m 2 h), the operating flux of the fourth reactor is 2.5 L / (m 2 h), all adopt the operation mode of pumping for 10 minutes and stopping for 2 minutes. The sludge concent...

Embodiment 3

[0031] The flat membrane module adopts PVDF with a pore size of 0.2 μm to treat high-concentration excess activated sludge. It is divided into four sections. The total area of the flat membrane module is 700 m 2 . The membrane area of the first reactor 1 and the second reactor 2 are both 218.8 m 2 , the membrane area of the third reactor 3 is 175 m 2 , the membrane area of the fourth reactor 4 is 87.6 m 2 . The amount of mud entering is 200 m 3 / d, the hydraulic retention time is 6.8 h, the sludge concentration is about 10 g / L, and the operating flux of the first reactor 1 is 18.3 L / (m 2 h), the operating flux of the second reactor 2 is 10.5 L / (m 2 h), the operating flux of the third reactor 3 is 8 L / (m 2 h), the operating flux of the fourth reactor 4 is 4 L / (m 2 h), all adopt the operation mode of pumping for 10 minutes and stopping for 2 minutes. The sludge concentration in the first reactor is maintained at 18 g / L, the sludge concentration in the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com