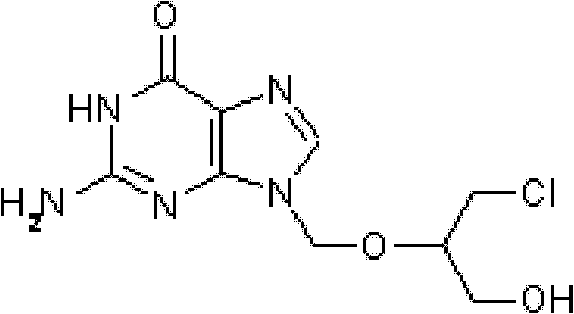

Refining method of ganciclovir

A technology of ganciclovir and refining method, which is applied in the field of chemical refining, can solve the problems of reducing the impurity content of monocloganciclovir, etc., and achieve the effects of short refining period, high yield and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Put 30 g of crude ganciclovir with a monocloganciclovir content of 0.27%, 180 ml of water and 180 ml of DMF into a reaction flask, stir and heat to 93°C to dissolve, slowly cool to 70-80°C, keep stirring for 1 hour, and then Slowly cool to 40-50°C, stir for 1 hour, then cool to 20-30°C, stir for 2 hours, filter with suction, wash the filter cake with an appropriate amount of water, dry the crystallized product, and obtain 26.7g of ganciclovir fine product, single Chlorine impurity 0.048%.

Embodiment 2

[0016] Put 30g of crude ganciclovir with a monocloganciclovir content of 0.27%, 150ml of water and 210ml of DMF into the reaction bottle, stir and heat to dissolve at 100°C, slowly cool to 70-80°C, keep stirring for 1 hour, and then slowly Cool to 40-50°C, stir for 1 hour, then cool to 20-30°C, stir for 2 hours, filter with suction, wash the filter cake with an appropriate amount of water, take the crystallized product and dry to obtain 27.0g of ganciclovir fine product, monochlorinated Impurities 0.08%.

Embodiment 3

[0018] Put 30g of crude ganciclovir with a monocloganciclovir content of 0.27%, 300ml of water and 300ml of DMF into the reaction bottle, stir and heat to dissolve, slowly cool to 70-80°C, keep stirring for 1 hour, and then slowly cool to 40-50°C, stirred for 1 hour, then cooled to 20-30°C, stirred for 2 hours, filtered with suction, soaked in an appropriate amount of water to wash the filter cake, dried the crystallized product, and obtained 25.9 g of ganciclovir fine product, monoclonal impurity 0.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com