Heat treatment device for gradient of disk component

A technology for heat treatment devices and disc-shaped parts, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of small temperature gradients and low treatment temperatures, and achieve the effects of large temperature gradients, increased treatment temperatures, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

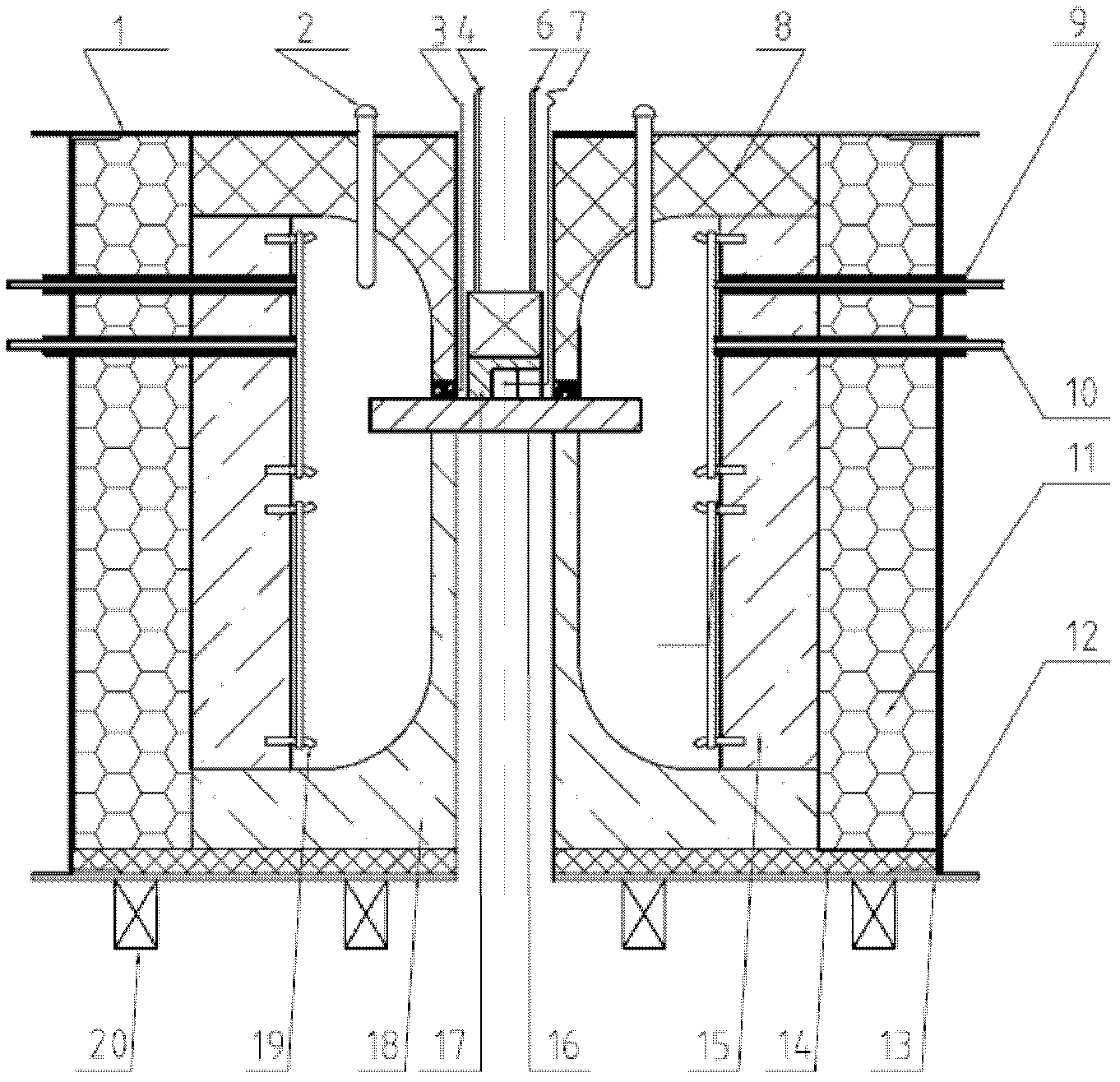

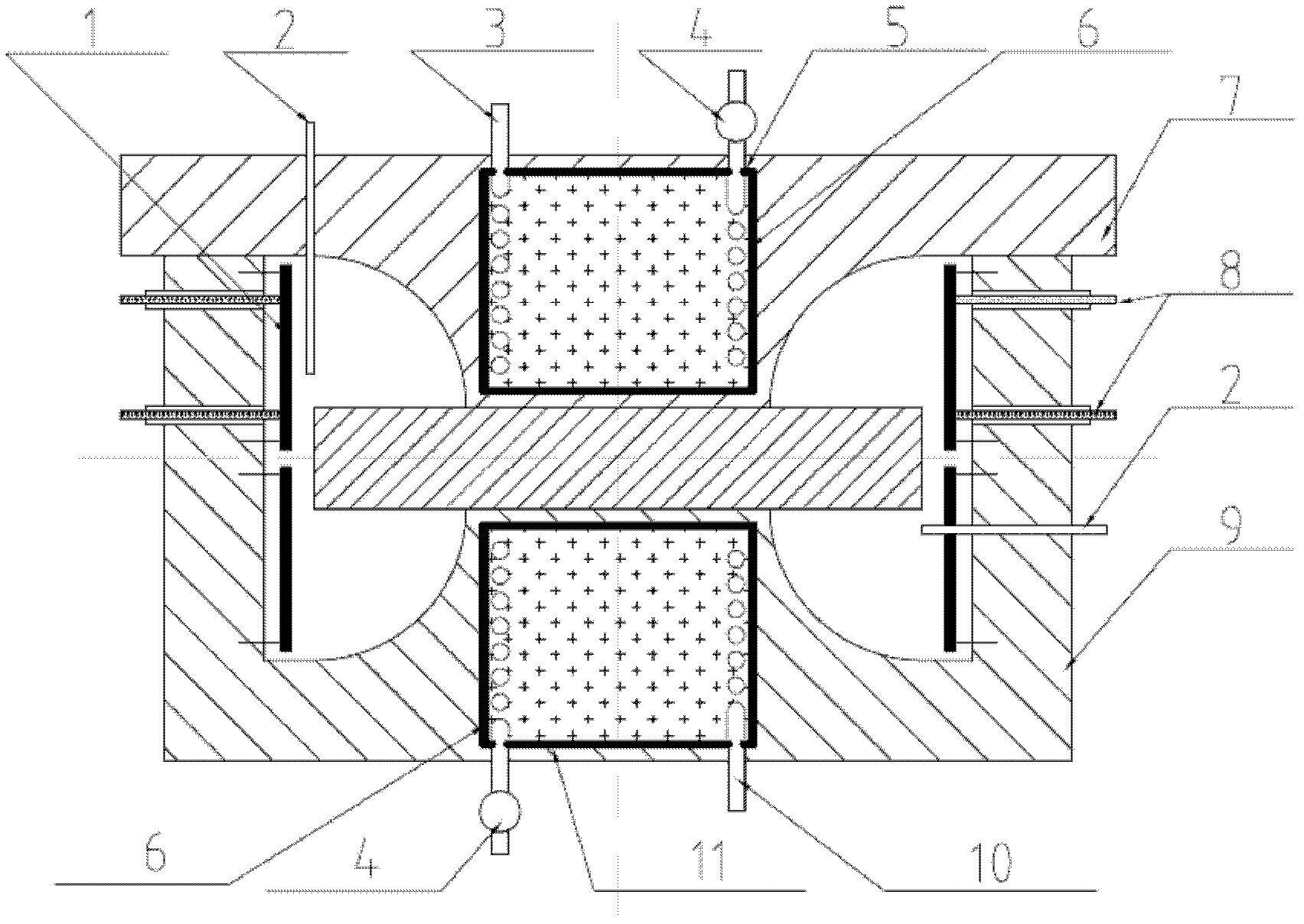

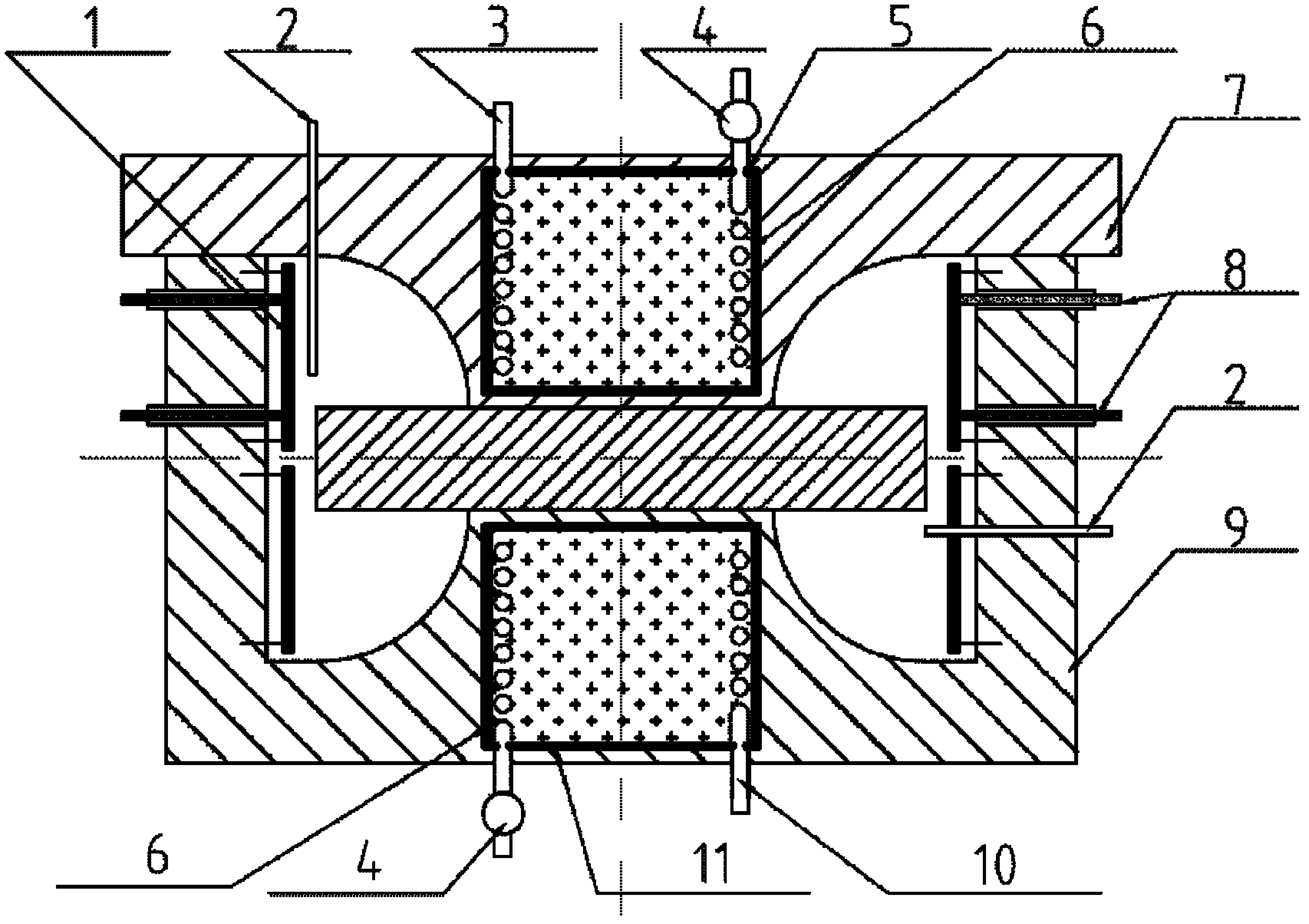

[0014] Refer to attached figure 2 , the present invention includes a resistance band 1, a thermocouple 2, an upper cooling pipe 3, a circulation pump 4, an upper cooling box 5, a heat conduction salt 6, an upper furnace body 7, a terminal post 8, a lower furnace body 9, a lower cooling pipe 10 and a lower Cooling box 11. Among them, thermocouple 2, upper cooling box 5, upper cooling pipeline 10, heat conduction salt 6 and circulation pump 4 are arranged on upper furnace body 7; , heat conduction salt 6 and circulating pump 4, high-performance resistance band 1 (0Cr27Al7Mo2 iron chromium aluminum resistance band, rated heating temperature 1400 ° C, rated heating rate 10 ° C / s) is also arranged, and the edge of the disc-shaped part is tested. Radiant heating. Both the upper cooling box 3 and the lower cooling box 11 are filled with heat conducting salt 6, and the specific composition is BaCl with a mass ratio of 50%. 2 , 30% KCl and 20% NaCl, and arrange cooling pipes to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com