Method for purifying ethylene glycol product

A technology for ethylene glycol and products, applied in the field of ethylene glycol product purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

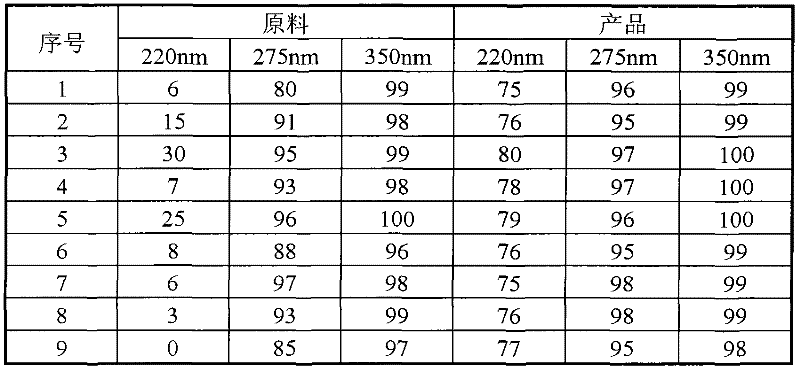

[0018] Load 100 grams of 35% Cu+5% Zn / SiO by catalyst weight in a fixed bed reactor 2 The copper-containing solid oxide catalyst is passed into the ethylene glycol product raw material obtained by the hydrogenation of dimethyl oxalate, and the purity is 99.8% (the ultraviolet transmittance of the raw material is as shown in Table 1), at a temperature of 150 ° C, a pressure of 2.0 MPa, airspeed 10 hours -1 , under the condition that the hydrogen / alcohol molar ratio is 5:1, pass through the copper-containing solid oxide catalyst, contact with the catalyst, and obtain the purified ethylene glycol effluent, and the result after rectification is shown in the following table:

[0019] Table 1

[0020]

Embodiment 10~18

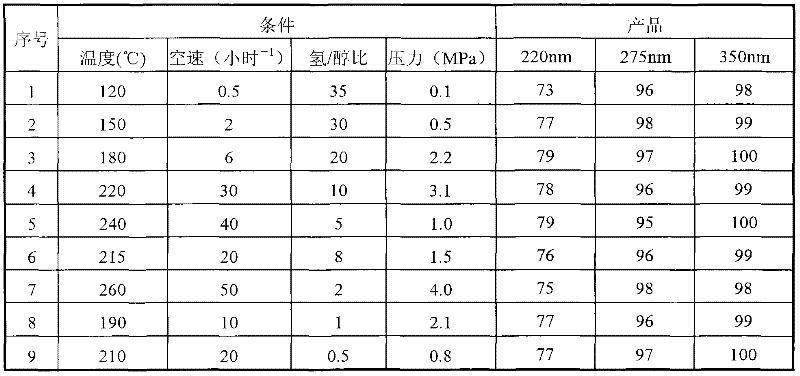

[0022] Load 100 grams of 40% Cu+10% Zn / SiO by catalyst weight in a fixed bed reactor 2 The copper-containing solid oxide catalyst is passed through the ethylene glycol product obtained by the hydrogenation of dimethyl oxalate as a raw material, and the purity is 99.8% (the ultraviolet transmittance of the raw material is 6 at 220nm, 91 at 275nm, and 91 at 350nm. 96), the results obtained under different reaction conditions are shown in the table below:

[0023] Table 2

[0024]

Embodiment 19

[0026] Load 100 grams of 20% Cu+5% Ni / SiO by catalyst weight in a fixed bed reactor 2 The copper-containing solid oxide catalyst is passed through the ethylene glycol product obtained by hydrogenation of diethyl oxalate as a raw material, and the purity is 99.9% (the ultraviolet transmittance of the raw material is 3 at 220nm, 92 at 275nm, and 92 at 350nm. is 97), at a temperature of 190°C, a pressure of 2.0MPa, and a space velocity of 5 hours -1 , under the condition that the hydrogen / alcohol molar ratio is 2:1, pass through a copper-containing solid oxide catalyst, contact with the catalyst to obtain purified ethylene glycol effluent, and the result after rectification is: the ultraviolet transmittance is at 220nm 78, 96 at 275nm, and 100 at 350nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com