Polyolefin microporous membrane and preparation method thereof

A polyolefin microporous film, polyolefin technology, applied in the field of polyolefin materials, can solve the problems of poor product performance uniformity, affecting product quality, uneven dispersion, etc. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

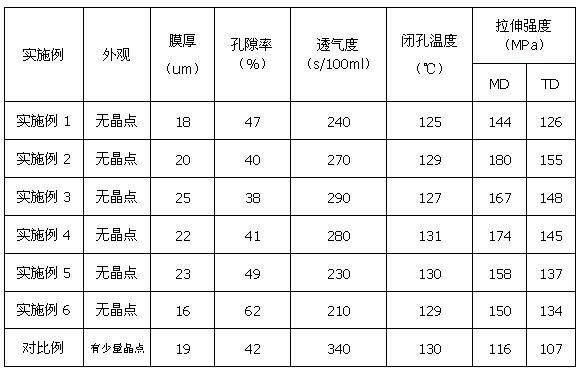

Examples

preparation example Construction

[0034] The preparation process of the modified ultra-high molecular weight polyolefin masterbatch is as follows:

[0035] Add 40-70% ultra-high molecular weight polyethylene resin, 10-25% modified resin, 15-25% additive and 5-10% lubricant into the mixer, and mix at a temperature of 200-260°C into a blend, extruded and granulated by a screw extruder to obtain a modified ultra-high molecular weight polyolefin masterbatch.

[0036] In the preparation of non-porous slabs, in order to achieve the purpose of mixing the modified ultra-high molecular weight polyolefin masterbatch with high-density polyolefin resin and plasticizer, before entering the twin-screw extruder, the present invention uses pre-mixed In the method of stirring and mixing these raw materials, after mixing and dispersing evenly, they are added to the twin-screw extruder.

[0037] In the present invention, the above-mentioned temperature of mixing and dispersing the raw materials in the mixer is not particularly ...

Embodiment 1

[0045] 1. At a temperature of 240°C, 7 kg of ultra-high molecular weight polyethylene resin with a weight average molecular weight of 5 million, 1 kg of polyethylene resin with a molecular weight of 5000, tetra{β-(3,5-di-tert-butyl-4- Add 1.5 kg of hydroxyphenyl) propionate} pentaerythritol ester and 0.5 kg of magnesium stearate into a mixer, mix evenly, extrude and granulate through a screw extruder to obtain a modified ultra-high molecular weight polyolefin masterbatch.

[0046] 2. At room temperature, add 10 kg of modified ultra-high molecular weight polyolefin masterbatch and 20 kg of high-density polyolefin resin with a weight-average molecular weight of 200,000 to the mixer, and add it to the twin-screw extruder after being uniform. At the same time, 70 kg of liquid paraffin was added, melted at a temperature of 210° C., extruded through a die, and cooled and solidified by a cooling roll at 40° C. to obtain a non-porous thick sheet.

[0047] 3. Simultaneously biaxially s...

Embodiment 2

[0051] 1. At a temperature of 260°C, 9 kg of ultra-high molecular weight polyethylene resin with a weight average molecular weight of 4 million, 2 kg of polyethylene resin with a molecular weight of 5000, 1 kg of dioctyl phthalate, and dioctadecyl pentaerythritol Add 1.5 kilograms of bisphosphite and 1.5 kilograms of polyethylene wax into a mixer, mix uniformly, and then extrude and granulate through a screw extruder to obtain modified ultra-high molecular weight polyolefin masterbatches.

[0052] 2. At room temperature, add 15 kg of modified ultra-high molecular weight polyolefin masterbatch and 30 kg of high-density polyolefin resin with a weight-average molecular weight of 800,000 into the mixer, and add it to the twin-screw extruder after being uniform. At the same time, 55 kg of liquid paraffin was added, melted at a temperature of 230° C., extruded through a die, and cooled and solidified by a cooling roll at 30° C. to obtain a non-porous thick sheet.

[0053] 3. Simulta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com