Miniature solid rocket engine

A solid rocket and motor technology, which is applied to rocket motor devices, machines/engines, mechanical equipment, etc., can solve the problems of difficult installation, high process requirements, small nozzle size, etc., and achieves convenient installation and operation, low process requirements, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

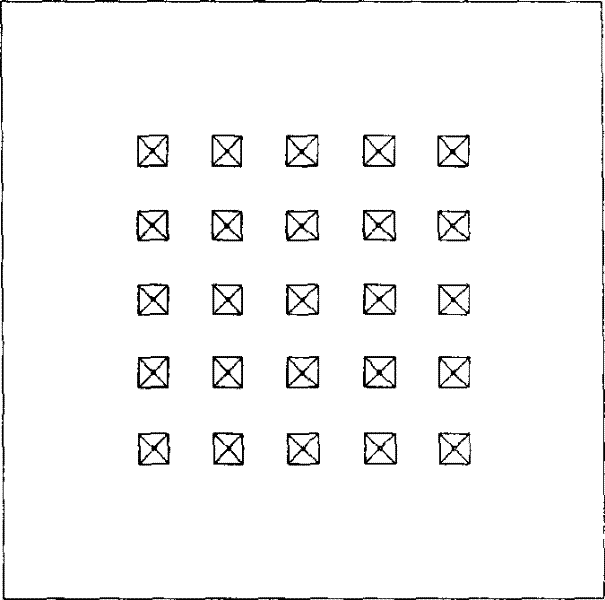

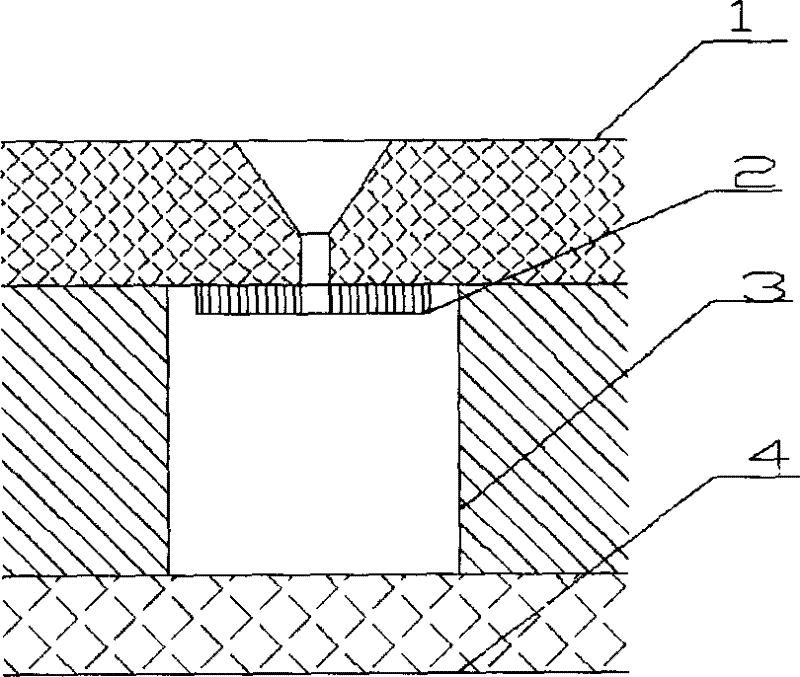

[0021] The present embodiment is a kind of miniature solid rocket motor. The micro solid rocket motor structure is composed of four parts, including: nozzle layer 1, ignition resistance wire 2, combustion chamber layer 3 and end cover layer 4; wherein, nozzle layer 1 and combustion chamber layer 3 are bonded together; ignition The resistance wire 2 and the nozzle layer are bonded together; the combustion chamber layer 3 and the end cover layer 4 are bonded together. The nozzle layer, the combustion chamber layer and the end cover layer are all made of silicon wafers through MEMS technology; a number of miniature solid rocket motors are integrated on a chip.

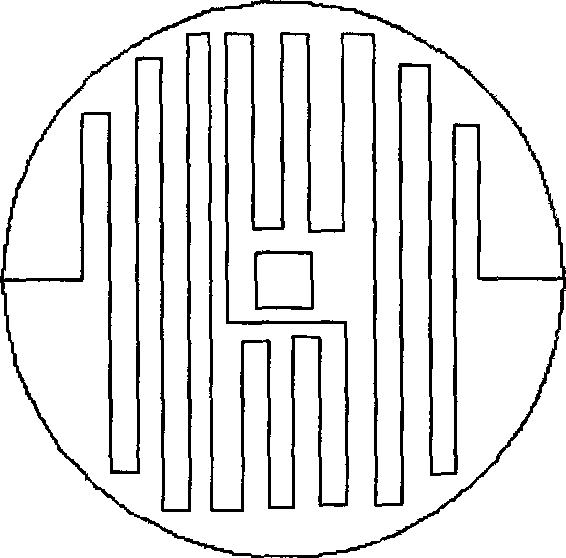

[0022] Such as figure 1 As shown, the ignition resistance wire 2 connection line of the miniature solid rocket motor of the present invention is embedded in the nozzle layer 1 rear end engraved with fine grooves and the position corresponding to the front end of the combustion chamber layer 3 along the diameter direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com