Laser gas analyzer for multicomponent multiplexing measurement

A laser gas and multi-component technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of complex installation on site, multi-welded flange openings, and unavailability, so as to improve accuracy, avoid optical noise, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

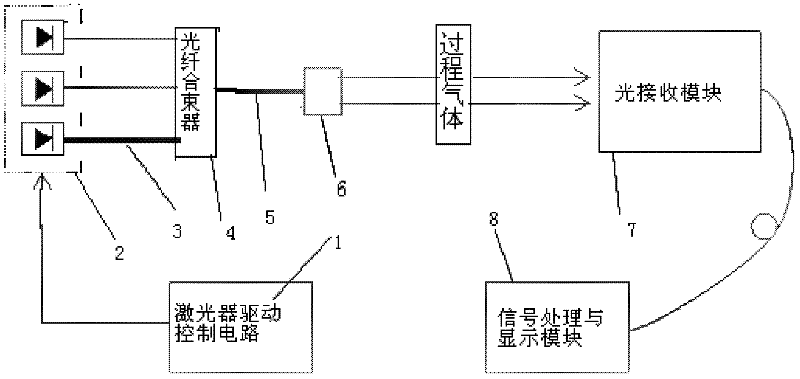

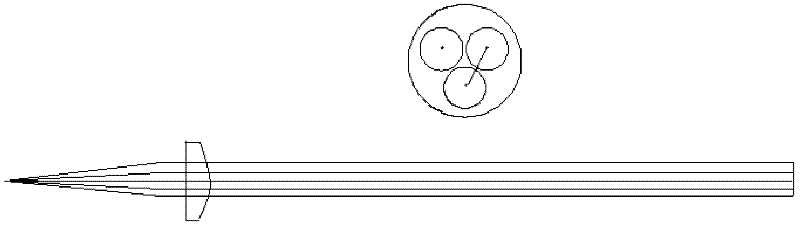

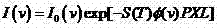

[0016] Such as figure 1 As shown, a laser gas analyzer for multi-component multiplexing measurement includes a laser drive control circuit 1, three packaged lasers 2, an optical fiber beam combiner 3, a collimator lens 6, a light receiving module 7 and signal processing and Display module 8, the first packaged laser measures the concentration of oxygen, the second and the third packaged laser measure the concentration of carbon monoxide and carbon dioxide respectively, and the laser drive control circuit 1 modulates and drives the three packaged lasers 2 to emit Lasers of different wavelengths, the wavelength of the laser emitted by the first packaged laser is 0.7 μm, the wavelength of the laser emitted by the second and third packaged lasers is 1.5 μm, and the pigtails of the three packaged lasers 2 are respectively connected to a single mode optical fiber 3, three single-mode optical fibers 3 are synthesized into an optical fiber bundle 5 after passing through the optical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com