Refractive index sensor and detection method thereof

A refractive index sensor and sensor chip technology, applied in the field of optical measurement, can solve the problems of intensity fluctuation noise sensitivity, high cost, and inaccurate data measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

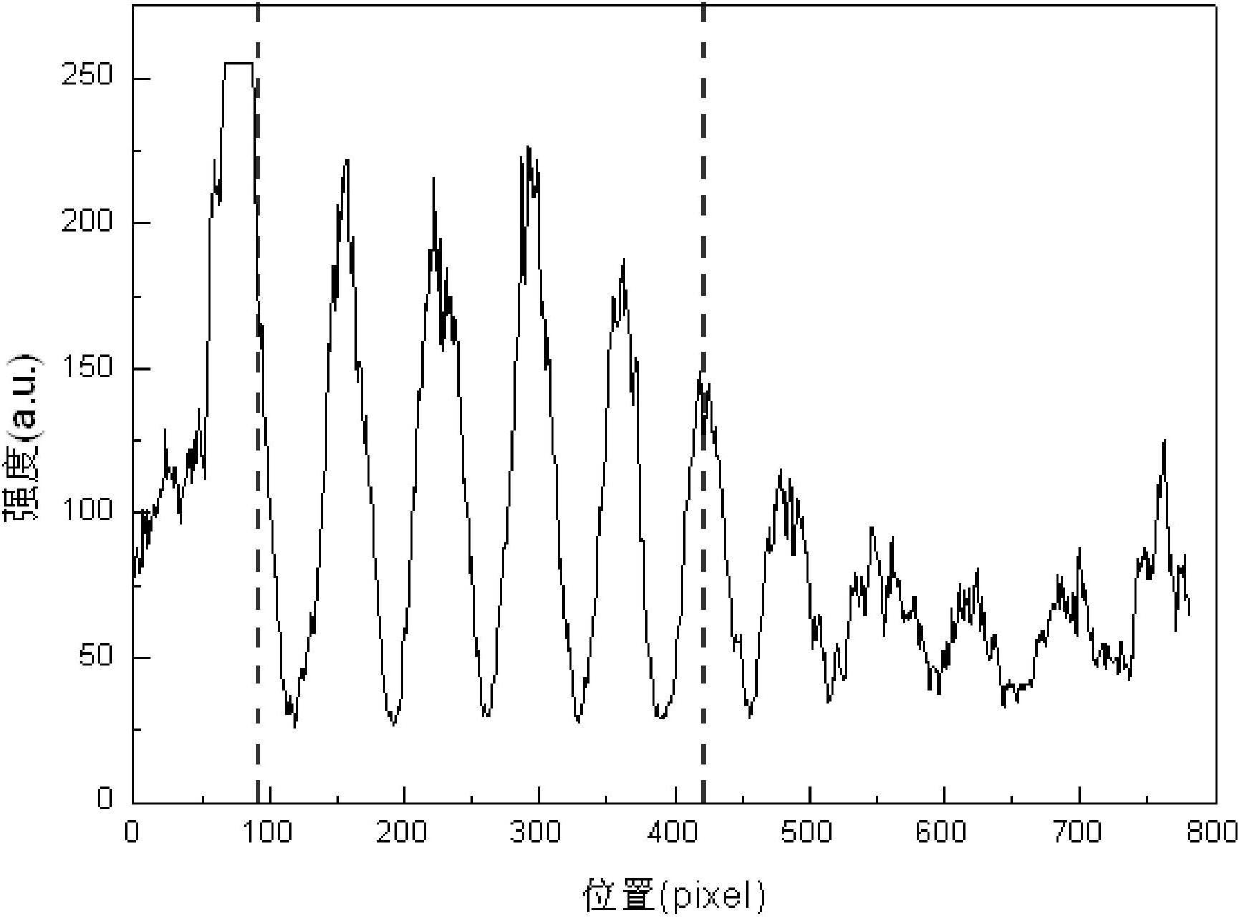

[0039] The specific implementation of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

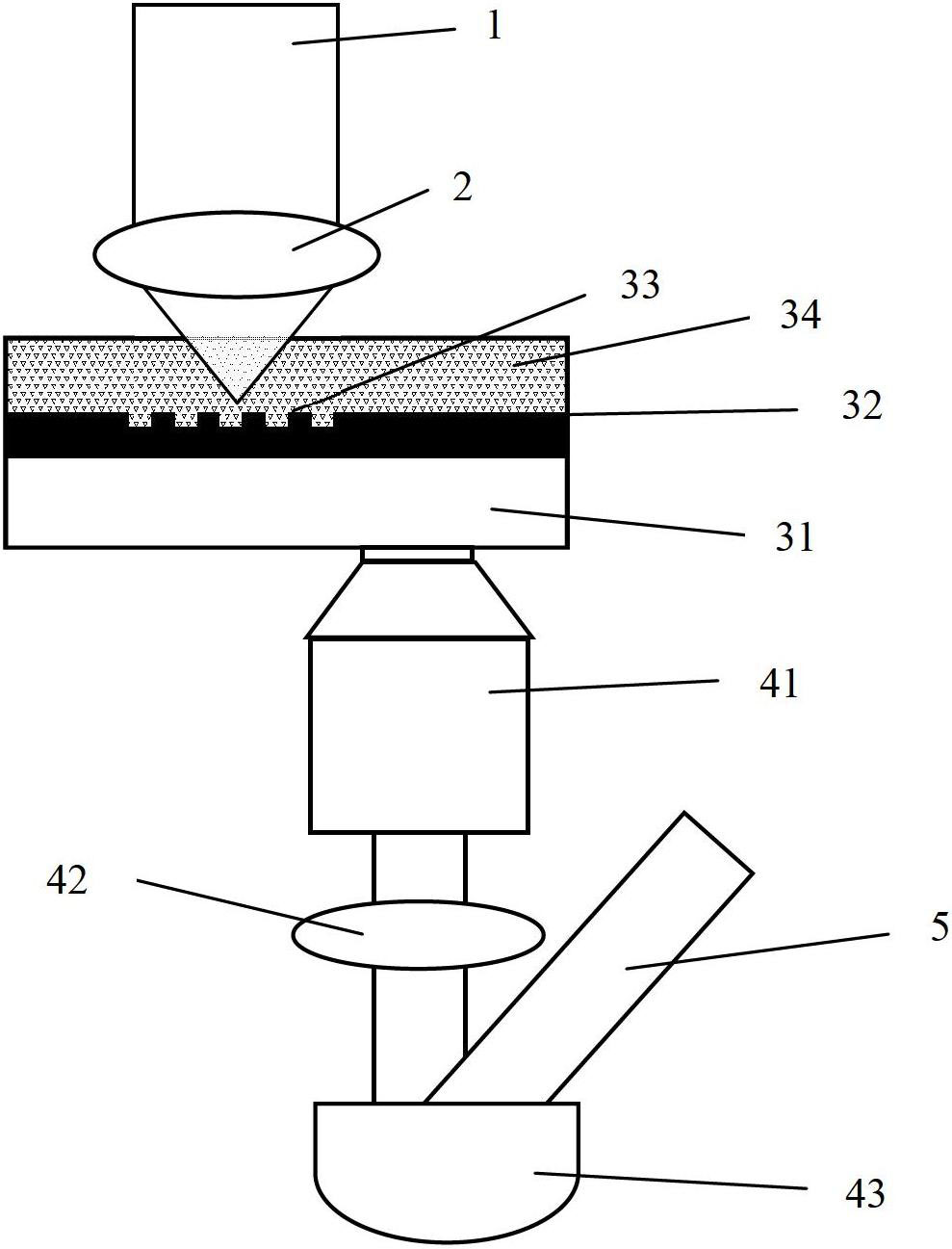

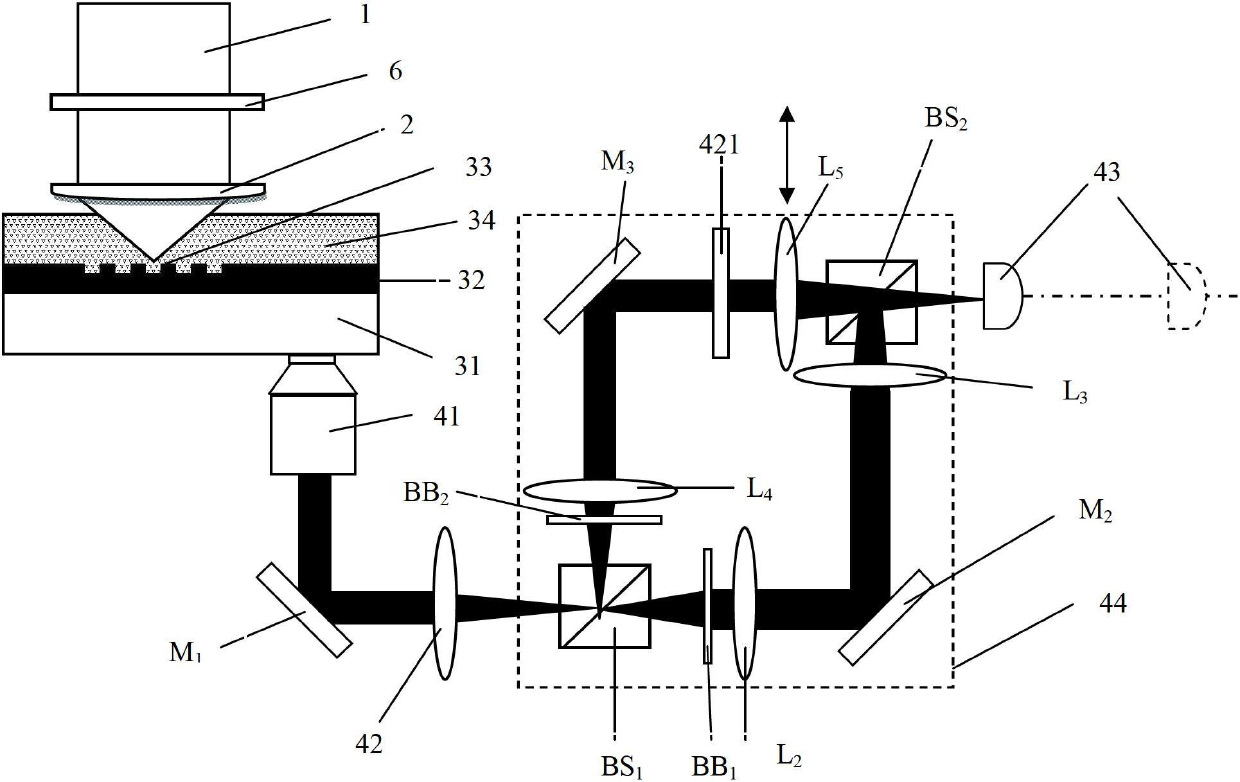

[0040] Such as figure 1 As shown, the refractive index sensor of the present invention includes: an excitation device and a leakage radiation microscope system; the excitation device includes a monochromatic light source 1, a focusing device 2 and a sensor chip; the radiation leakage microscope system includes an oil immersion objective lens 41, an imaging lens 42 and a CCD camera 43 ; the sensor chip further includes: a grating structure 33 is engraved on the metal film 32 , the sample 34 to be tested is placed on the metal film 32 , and the metal film 32 is plated on the transparent substrate 31 .

[0041] Among them, the size of glass as the transparent substrate 31 is 24mm×24mm, and the thickness is 0.17mm; the metal film 32 with a thickness of 50nm is plated on the transparent substrate by electron beam evaporati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com