Composite sensing membrane composed of polypyrrole, fluorescein isothiocyanate and porous alumina as well as preparation method and application thereof

A technology of fluorescein isothiocyanate and porous alumina, which is applied in the fields of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems that cannot be used for other purposes, cannot be prepared, cannot be used, etc., and achieve the effect of excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The concrete steps of preparation are:

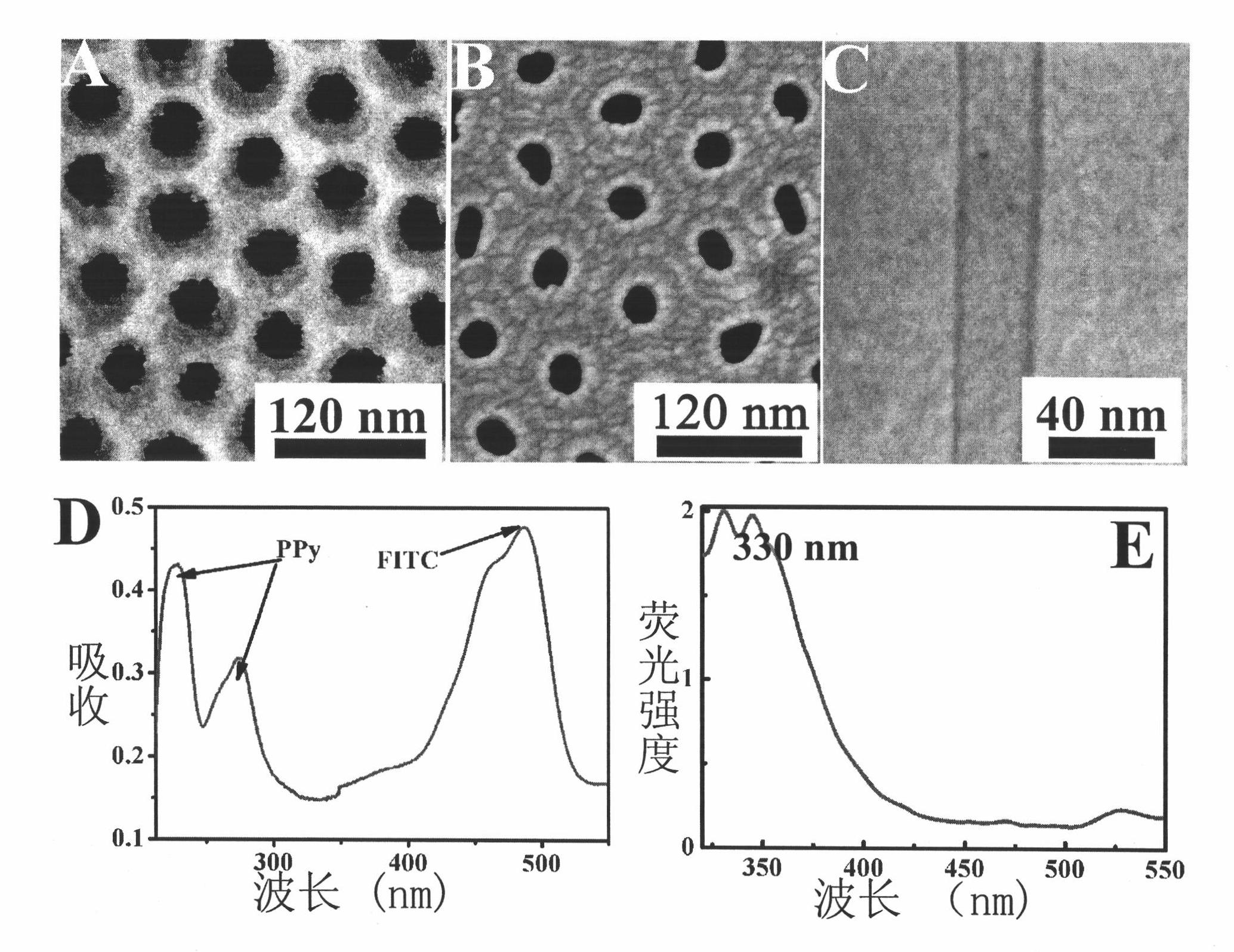

[0029] Step 1, first drop the 0.4M pyrrole ethanol aqueous solution and the 0.8M ferric chloride aqueous solution onto the porous alumina film successively; After the aluminum film was placed under a negative pressure of 0.06 MPa for 12 minutes, it was cleaned ultrasonically with deionized water and ethanol, and an approximate figure 1 B and figure 1 Its surface and hole inner wall shown in C are covered with the porous aluminum oxide film of polypyrrole.

[0030] Step 2, first soak the porous alumina film covered with polypyrrole on the surface and the inner wall of the hole for 1.2h in a concentration of 10-3M fluorescein isothiocyanate ethanol solution; then use ethanol to wash off the porous alumina film Fluorescein isothiocyanate on the surface, made approximately figure 1 D and figure 1 The composite sensing membrane composed of polypyrrole, fluorescein isothiocyanate and porous alumina shown in the curve in E.

Embodiment 2

[0032] The concrete steps of preparation are:

[0033] Step 1, first drip the 0.45M pyrrole ethanol aqueous solution and the 0.9M ferric chloride aqueous solution onto the porous alumina film successively; After the aluminum film was placed under a negative pressure of 0.07MPa for 11.5min, it was cleaned ultrasonically with deionized water and ethanol, and an approximate figure 1 B and figure 1 Its surface and hole inner wall shown in C are covered with the porous aluminum oxide film of polypyrrole.

[0034] Step 2, first place the porous alumina film covered with polypyrrole on the surface and the inner wall of the hole at a concentration of 0.5 × 10 -3 Soak in the fluorescein isothiocyanate ethanol solution of M for 1.2h; then use ethanol to wash off the fluorescein isothiocyanate on the surface of the porous alumina film, and obtain a product similar to figure 1 D and figure 1 The composite sensing membrane composed of polypyrrole, fluorescein isothiocyanate and porous ...

Embodiment 3

[0036] The concrete steps of preparation are:

[0037] Step 1, first drop the 0.5M pyrrole ethanol aqueous solution and the 1M ferric chloride aqueous solution onto the porous alumina film successively; After the film was placed under a negative pressure of 0.08MPa for 11 minutes, it was ultrasonically cleaned with deionized water and ethanol to obtain the following figure 1 B and figure 1 Its surface and hole inner wall shown in C are covered with the porous aluminum oxide film of polypyrrole.

[0038] Step 2, first place the porous alumina film covered with polypyrrole on the surface and the inner wall of the hole at a concentration of 10 -4 Soak in the fluorescein isothiocyanate ethanol solution of M for 1.1h; then use ethanol to wash off the fluorescein isothiocyanate on the surface of the porous aluminum oxide film to obtain the following figure 1 D and figure 1 The composite sensing membrane composed of polypyrrole, fluorescein isothiocyanate and porous alumina shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com