Catalyst for catalyzing dimethyl sulfide and hydrogen sulfide to synthesize methyl mercaptan, and preparation method and application thereof

A technology of methyl sulfide and hydrogen sulfide, applied in the field of preparation of the catalyst, can solve the problems of low conversion efficiency of methyl sulfide, generation of by-products and the like, and achieve the effects of convenient industrial production, efficient catalysis and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

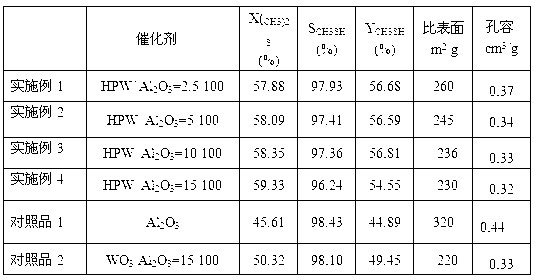

[0029] Weigh 0.78g of phosphotungstic acid (HPW), dissolve it in 18.0ml of distilled water, and stir on an electromagnetic stirrer for 1 hour to obtain a phosphotungstic acid impregnation solution; then weigh 15g of γ-alumina (γ-Al 2 o 3 ) into phosphotungstic acid impregnation solution for 8 hours, filtered, and recovered the filter residue to obtain the catalyst precursor; then the catalyst precursor was dried at 25°C, then baked at 120°C for 8 hours to constant weight, and then dried at 450°C Calcined at lower temperature for 3 hours to obtain a catalyst that catalyzes the synthesis of methyl mercaptan from methyl sulfide and hydrogen sulfide.

[0030] The weight ratio of the catalyst phosphotungstic acid and γ-alumina prepared in this example is 2.5:100, that is, HPW / Al 2 o 3 =2.5 / 100.

[0031] The activity evaluation of the catalyst was carried out on a fixed bed reaction system, the catalyst loading was 2mL, the particle size was 30 mesh, and the reaction raw material...

Embodiment 2

[0033] The preparation method of the catalyst that catalyzes the synthesis of methyl mercaptan from methyl sulfide and hydrogen sulfide is the same as in Example 1, except that 1.56 g of phosphotungstic acid is weighed, the stirring time is 2 hours, the immersion time is 4 hours, and the calcination temperature is 550°C .

[0034] The weight ratio of the catalyst phosphotungstic acid and γ-alumina prepared in this example is 5:100, that is, HPW / Al 2 o 3 =5 / 100.

[0035] The activity evaluation of the catalyst is the same as in Example 1, except that the molar ratio of the reaction raw material hydrogen sulfide to dimethyl sulfide is 6:1, that is, H 2 S / DMS=6, the particle size is 60 mesh, the reaction temperature is 320°C, the pressure is 0.9MPa, and the space velocity is 1200h -1 Under the condition of catalytic reaction, CH 3 SCH 3 Conversion and CH 3 The SH yield is shown in Table 1.

Embodiment 3

[0037] The preparation method of the catalyst that catalyzes the synthesis of methyl mercaptan from methyl sulfide and hydrogen sulfide is the same as in Example 1, except that 3.12 g of phosphotungstic acid is weighed, the stirring time is 1.5 hours, the immersion time is 6 hours, and the calcination temperature is 500°C .

[0038] The weight ratio of the catalyst phosphotungstic acid and γ-alumina prepared in this example is 10:100, that is, HPW / Al 2 o 3 =10 / 100.

[0039] The activity evaluation of catalyst is the same as embodiment 1, and difference is that reaction raw material hydrogen sulfide and methyl sulfide mol ratio are 1, i.e. H 2 S / DMS=1:1, the particle size is 50 mesh, the reaction temperature is 550°C, the pressure is 0.1MPa, and the space velocity is 5000h -1 Under the condition of catalytic reaction, CH 3 SCH 3 Conversion and CH 3 The SH yield is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com