Field fast production method of lawn grass strengthening biological fertilizers

A technology of biological fertilizer and production method, applied in the direction of organic fertilizer and the like, can solve the problems of complex preparation method of turfgrass strengthening biological fertilizer, difficult to widely apply and popularize, time-consuming, etc., so as to improve photosynthesis efficiency and improve nutrient utilization effect. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

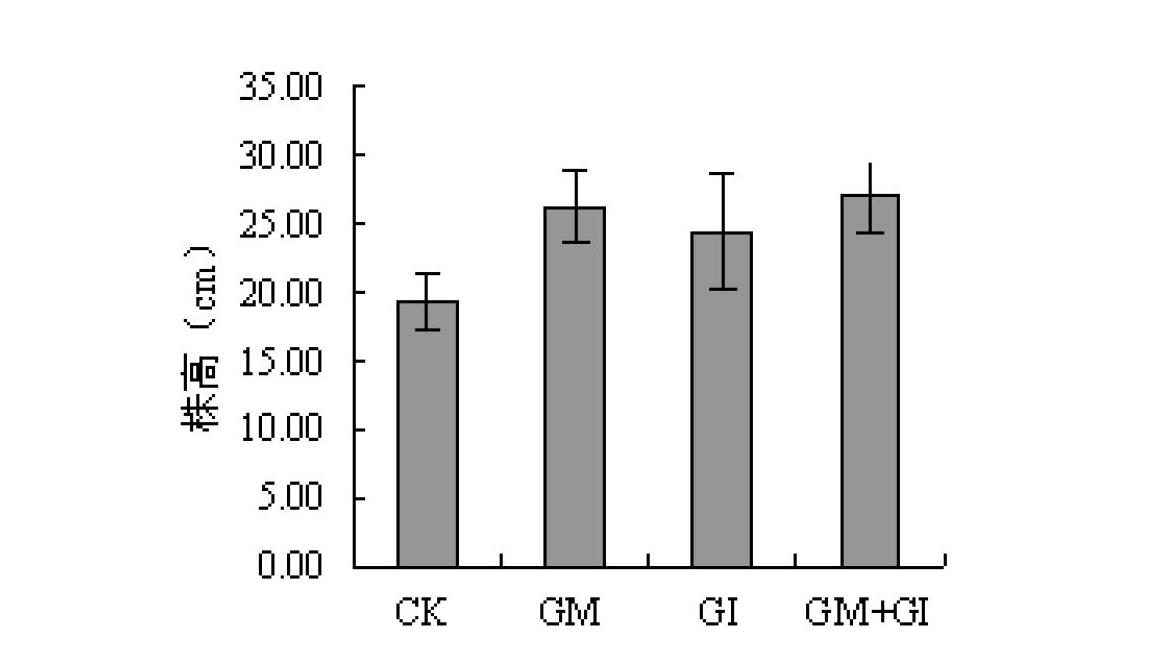

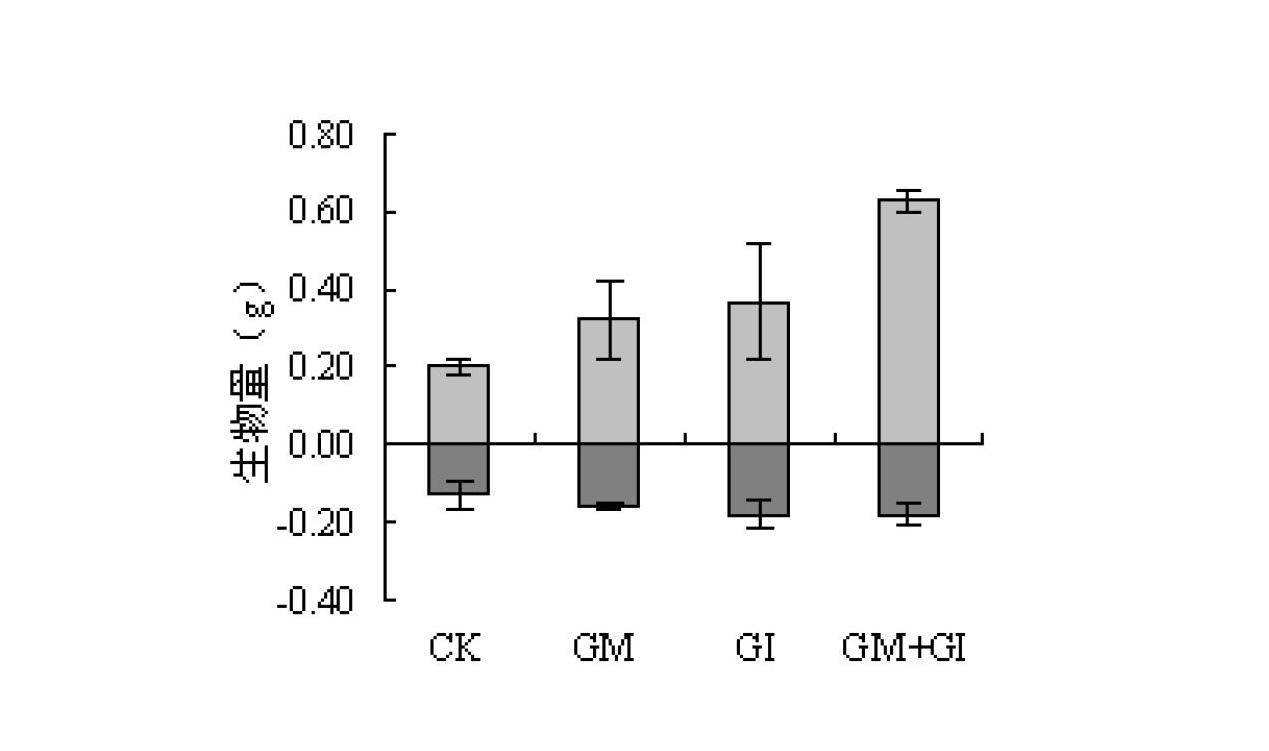

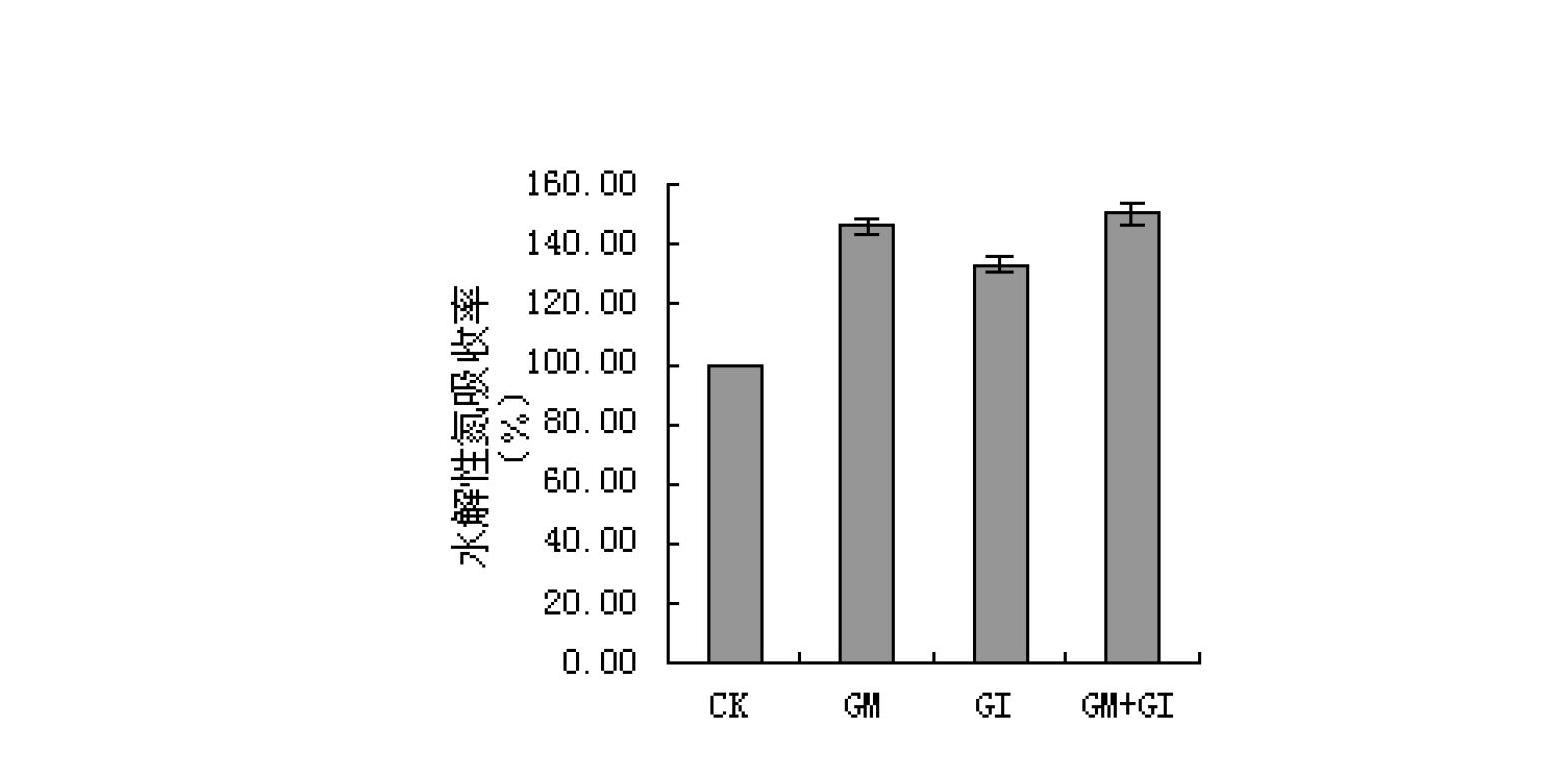

[0011] The specific embodiment one: the rapid production method in the field of the turfgrass strong biological fertilizer of the present embodiment, carry out according to the following steps: one, soil, river sand and vermiculite cross 10 mesh soil sieves respectively, then soil, river sand and vermiculite Mixed by volume ratio 2:5:3, as the substrate, the substrate was sterilized by high-pressure steam at 121°C for 2 hours, and the flower pot was washed and dried and then sterilized by ultraviolet light for 30 minutes; Soak in alcohol for 10 minutes, then rinse with distilled water for 3 times, and germinate at 30°C; 3. Put 2kg of sterilized substrate in each flower pot, spray sterile water until the water seeps out from the base of the flower pot, and put the Moses ball Cystis and Glomus intraradices are respectively inoculated into the matrix, and the inoculation amount is 20 spores for each flower pot, and then the germinated white clover seeds are evenly sprinkled; Spra...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: the pH value of the soil in step 1 is 7.5, the total nitrogen content is 7.34 g / kg, and the total phosphorus content is 16.83 g / kg. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of substrate and seeds in step 3 is 40:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com