Preparation method for sago starch modified by xanthan gum

A technology of xanthan gum and starch, which is applied in the field of starch preparation, can solve the problems of insolubility in cold water, poor shear ability and acid resistance of sago starch, and achieve the effect of not easy to break, easy to break, and good film-forming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

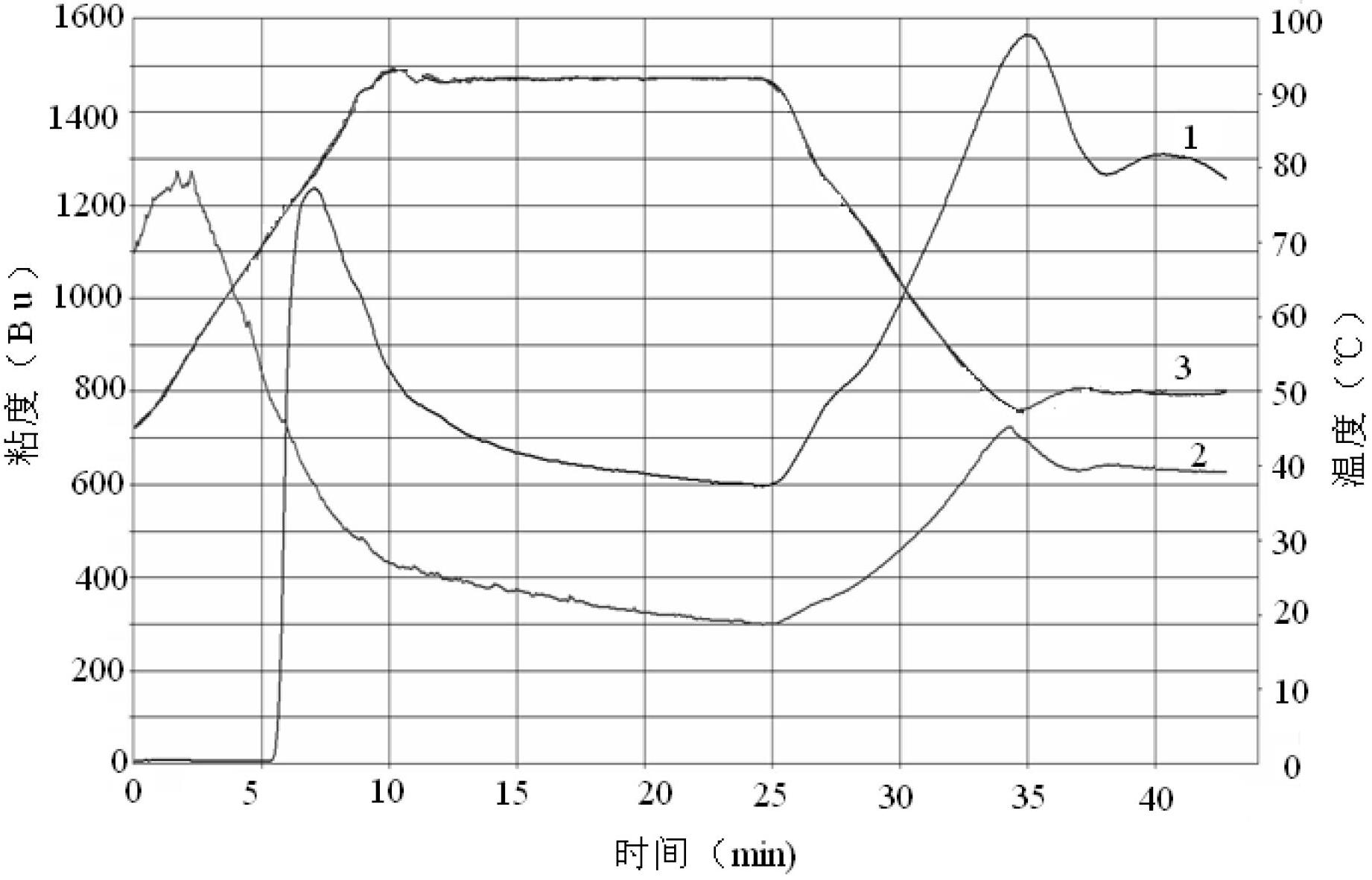

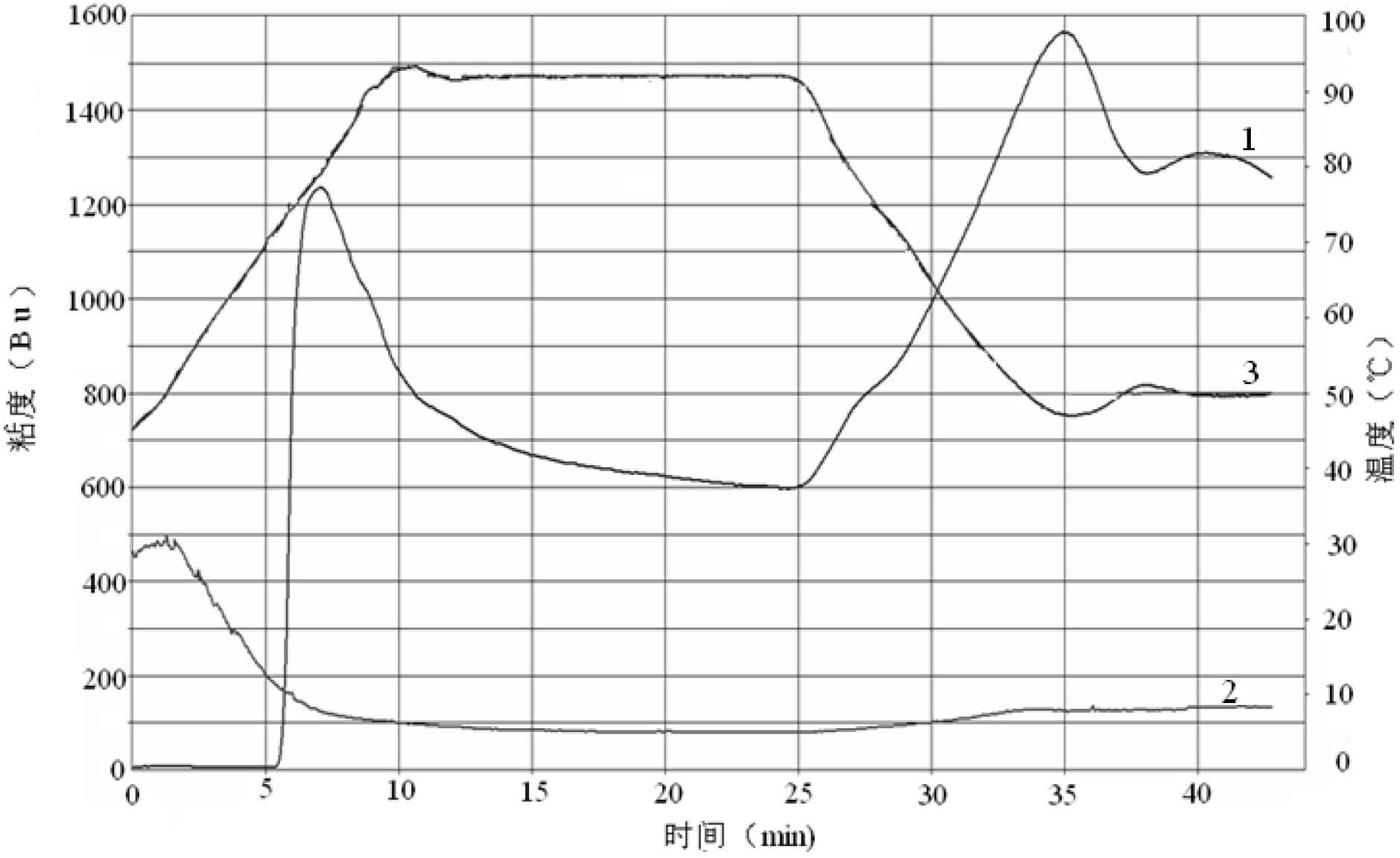

[0010] Specific embodiment one: the preparation method of a kind of xanthan gum modified sago starch of the present embodiment is carried out according to the following steps: one, the ratio of xanthan gum and pure water is 1g:10~15mL by mass volume ratio After mixing and stirring for 10-15 minutes, the xanthan gum solution is obtained; 2. After the sago starch and the xanthan gum solution obtained in step 1 are uniformly mixed in a ratio of 1g to 1-2mL by mass to volume, a mixed solution is obtained; 3. The mixed solution obtained in step 2 is pregelatinized, then pulverized, and sieved through a 40-mesh sieve to obtain xanthan gum modified sago starch.

[0011] The xanthan gum modified sago starch obtained in this embodiment has the characteristics of complete dissolution in normal temperature water, shear resistance, and acid resistance, which improves the shear resistance and acid resistance of sago starch, and can better meet the requirements of sago starch in Application...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the xanthan gum and pure water described in step 1 have a mass-to-volume ratio of 1 g: 12 mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 to 2 is that the sago starch and xanthan gum solution described in step 2 is 1 g: 1.2 mL by mass volume ratio. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

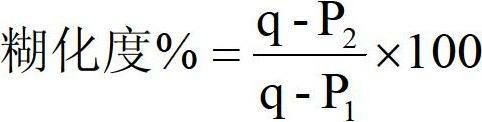

| gelatinization degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com