Method for preparing human urinary kallidinogenase crude product

A technology for urinary kininogenase and crude products, which is applied in the field of urine protein extraction, can solve problems such as difficult separation and purification, and affect KN purification, and achieve the effects of improving specific activity, low production cost, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

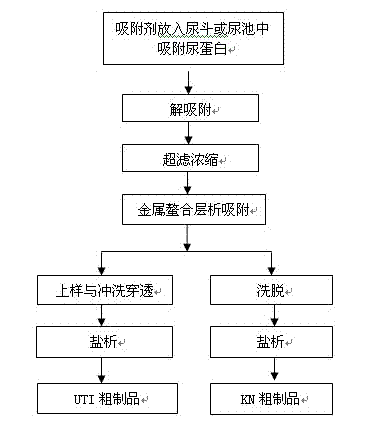

Method used

Image

Examples

Embodiment 1

[0036] 100 kg of macroporous anion exchange resin is used as the adsorbent. After regeneration treatment, the water is flushed to neutral, and put into a filter cloth bag with a pore size of 50 mesh. In the bucket or urinal, make urine or urine diluted with water flow through the resin, collect the resin that absorbs urine protein after 24 hours, wash the adsorbed resin with drinking water, and finally pack it into the column; use 0.1M NaCl was used for washing, 0.8M NaCl was used for elution, and the elution peaks were collected.

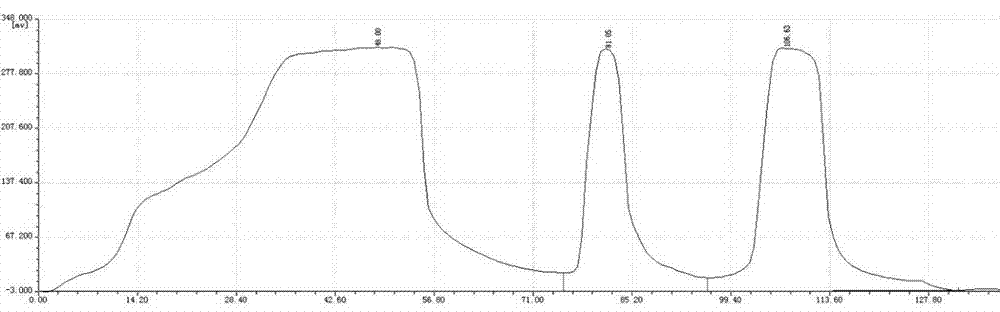

[0037] Use an ultrafiltration membrane with a molecular weight cutoff of 30K for ultrafiltration concentration, adjust the pH of the ultrafiltration concentrate to 8.0 and conductance to 2.2mS / cm, and the metal ion that has been balanced on the surface is Cu 2+ The metal chelating affinity chromatography column (Chelating sepharose FF); then use the balance solution (equilibrium solution formula: 0.02M phosphate buffer, 0.2M NaCl, pH8.0) to wash th...

Embodiment 2

[0043] 200 kg of macroporous anion exchange resin is used as the adsorbent. After regeneration treatment, the water is flushed to neutral, and put into a filter bag with a pore size of 50 mesh. In the bucket or urinal, make urine or urine diluted with water flow through the resin, collect the resin that absorbs urine protein after 24 hours, wash the adsorbed resin with drinking water, and finally pack it into the column; use 0.1M NaCl was used for washing; 0.8M NaCl was used for elution, and the elution peaks were collected.

[0044] Concentrate by ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 30K, adjust the pH of the ultrafiltration concentrate to 8.0 and conductance to 2.2mS / cm, and put the balanced Cu 2+ Metal chelate affinity chromatography column; then wash the metal chelate affinity chromatography column with equilibrium solution (equilibrium solution formula: 0.02M phosphate buffer, 0.2M NaCl, pH8.0), collect the sample penetration...

Embodiment 3

[0050] 100 kg of macroporous anion exchange resin is used as the adsorbent. After regeneration treatment, the water is flushed to neutral, and put into a filter cloth bag with a pore size of 50 mesh. In the bucket or urinal, make urine or urine diluted with water flow through the resin, collect the resin that absorbs urine protein after 24 hours, wash the adsorbed resin with drinking water, and finally pack it into the column; use 0.1M NaCl was used for washing, 0.5M NaCl was used for elution, and the elution peaks were collected.

[0051] Use an ultrafiltration membrane with a molecular weight cutoff of 30K for ultrafiltration concentration, adjust the pH of the ultrafiltration concentrate to 6 and the conductivity to 0.5mS / cm, and the metal ion that has been balanced on the surface is Zn 2+ The metal chelate affinity chromatography column; then use the balance solution (balance solution formula: 0.01M phosphate buffer, pH6.0) to wash the metal chelate affinity chromatography...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com