Preparation method of cocrystallized Al-Si alloy piston material

A technology of eutectic aluminum-silicon and aluminum alloy melts, which is applied in the field of preparation of eutectic aluminum-silicon alloy piston materials, can solve problems such as piston engine pistons that cannot adapt to the load and performance, broken ends of models, and cracks in combustion chamber ports. Achieve the effect of small thermal expansion coefficient, excellent high temperature performance, and promote heterogeneous nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

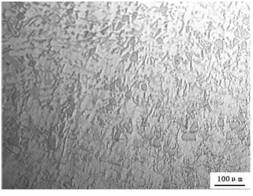

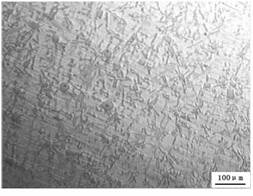

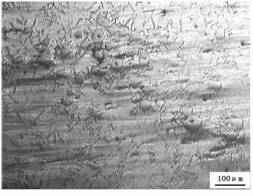

Image

Examples

Embodiment 1

[0057] (1) According to mass percentage Si: 12.3%, Cu: 4.2%, Mg: 0.8%, Ni: 2.8%, Zr: 0.060%, V: 0.060%, P: 0.010%, Al is the balance, weighed for remelting Aluminum ingots, magnesium ingots for remelting, industrial silicon, electrolytic copper, pure nickel plates and AlV5 (aluminum vanadium master alloy), AlZr10 ((aluminum zirconium master alloy), AlP3 (aluminum phosphorus master alloy); industrial silicon is broken Good 1~5cm 3 small pieces;

[0058] (2) Take the sodium-free refining agent by 0.15% of the total feeding mass;

[0059] (3) Put the industrial silicon, electrolytic copper, magnesium ingot for remelting, pure nickel plate, AlV5, AlZr10, ALP3, aluminum ingot for remelting and sodium-free refining agent in step (1), step (2) into the temperature Dry in a constant temperature preheating drying oven at 250°C for 3 hours;

[0060] (4) Put the dried industrial silicon, pure nickel plate, and aluminum ingot for remelting in step (3) into the CX-GR-150 industrial elec...

Embodiment 2

[0071] (1) Si: 12.5%, Cu: 4.4%, Mg: 0.8%, Ni: 3.0%, Zr: 0.065%, V: 0.065%, P: 0.010%, based on the mass percentage of the alloying elements in the aluminum-silicon alloy , and Al is the balance, respectively weigh the industrial silicon, electrolytic copper, magnesium ingots for remelting, pure nickel plate, AlV5, AlZr10, aluminum ingots for remelting and AlP3 master alloy; wherein industrial silicon is crushed 1 ~5cm 3 small pieces;

[0072] (2) take by weighing 0.15% of the total feeding quality of step (1) sodium-free refining agent;

[0073] (3) Put the industrial silicon, electrolytic copper, magnesium ingot for remelting, pure nickel plate, AlV5, AlZr10, AlP3, aluminum ingot for remelting and sodium-free refining agent in step (1), step (2) into the temperature Dry in a constant temperature preheating drying oven at 250°C for 3 hours;

[0074] (4) Put the dried industrial silicon, pure nickel plate and aluminum ingot for remelting in step (3) into the industrial elect...

Embodiment 3

[0084] (1) According to mass percentage Si: 12.5%, Cu: 4.0%, Mg: 0.9%, Ni: 3.0%, Zr: 0.07%, V: 0.07%, P: 0.014%, Al is the balance, and remelted Aluminum ingots, magnesium ingots for remelting, industrial silicon, electrolytic copper, AlNi20 (aluminum-nickel master alloy), AlV5 (aluminum-vanadium master alloy), AlZr10 ((aluminum-zirconium master alloy), AlP3 (aluminum-phosphorus master alloy); Industrial silicon is crushed 1~5cm 3 small pieces;

[0085] (2) Take the sodium-free refining agent by 0.16% of the total feeding mass;

[0086] (3) Put the industrial silicon, electrolytic copper, magnesium ingots for remelting, AlNi20, AlV5, AlZr10, AlP3, aluminum ingots for remelting and sodium-free refining agent in step (1) and step (2) at a temperature of 250°C Dry in a constant temperature preheating drying oven for 2 hours;

[0087] (4) Put the dried industrial silicon and aluminum ingots for remelting in step (3) into the CX-GR-150 industrial electric furnace, and set the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| High temperature tensile strength | aaaaa | aaaaa |

| High temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com