Method for improving hardness of Al-Si alloy

A technology of aluminum-silicon alloy and hardness, which is applied in the field of metal materials, can solve the problems of limited hardness of aluminum-silicon alloy, and achieve the effects of low cost, elimination of pores, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The aluminum-silicon alloy whose chemical composition (mass fraction wt%) is Al 93.03%, Si 4.63%, Cu 1.47%, Mg0.51%, Mn0.36 is placed in a KLX-12B box-type resistance furnace for solid solution treatment, The heating temperature is 520°C, the holding time is 120min, and the furnace is water-cooled. Then put the aluminum-silicon alloy after the above solid solution treatment on a CS-IIB six-sided top press for high-pressure treatment, the pressure is 1GPa, the heating temperature is 180°C, the holding time is 150min, and the power is turned off and the pressure is kept and cooled to room temperature. . The hardness test results are shown in Table 1.

Embodiment 2

[0014] The aluminum-silicon alloy whose chemical composition (mass fraction wt%) is Al 94.5%, Si 4.0%, Cu 1.0%, Mg0.3%, Mn0.2 is placed in a KLX-12B box-type resistance furnace for solid solution treatment, The heating temperature is 515°C, the holding time is 130min, and the furnace is water-cooled. Then put the aluminum-silicon alloy after the above solid solution treatment on a CS-IIB six-sided top press for high-pressure treatment, the pressure is 3GPa, the heating temperature is 200°C, the holding time is 120min, and the power is turned off and the pressure is kept and cooled to room temperature. . The hardness test results are shown in Table 1.

Embodiment 3

[0016] The aluminum-silicon alloy whose chemical composition (mass fraction wt%) is Al 90.6%, Si 6.0%, Cu 2.0%, Mg0.7%, Mn0.7 is placed in a KLX-12B box-type resistance furnace for solid solution treatment, The heating temperature is 525°C, the holding time is 150min, and the furnace is water-cooled. Then put the aluminum-silicon alloy after the above solid solution treatment on a CS-IIB six-sided top press for high-pressure treatment, the pressure is 2GPa, the heating temperature is 190°C, the holding time is 140min, and the power is turned off and the pressure is kept and cooled to room temperature. . The hardness test results are shown in Table 1.

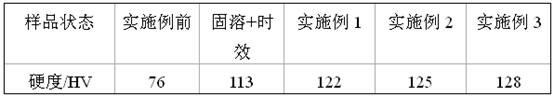

[0017] Table 1 Hardness test results of Al-Si alloys in different states

[0018]

[0019] Note: The solid solution + aging process is: heating at 520°C for 120 minutes, water cooling, and then holding at 180°C for 150 minutes.

[0020] The above experimental results show that the aluminum-silicon alloy has higher hardness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com