Method for producing hemicellulose by treating straw by ammonia water steam explosion technology

A technical treatment, hemicellulose technology, applied in the field of biomass pretreatment, can solve the problems of long pretreatment time and production cycle, large environmental impact, limited application, etc., and achieve the benefits of subsequent utilization, simple equipment, and improved utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

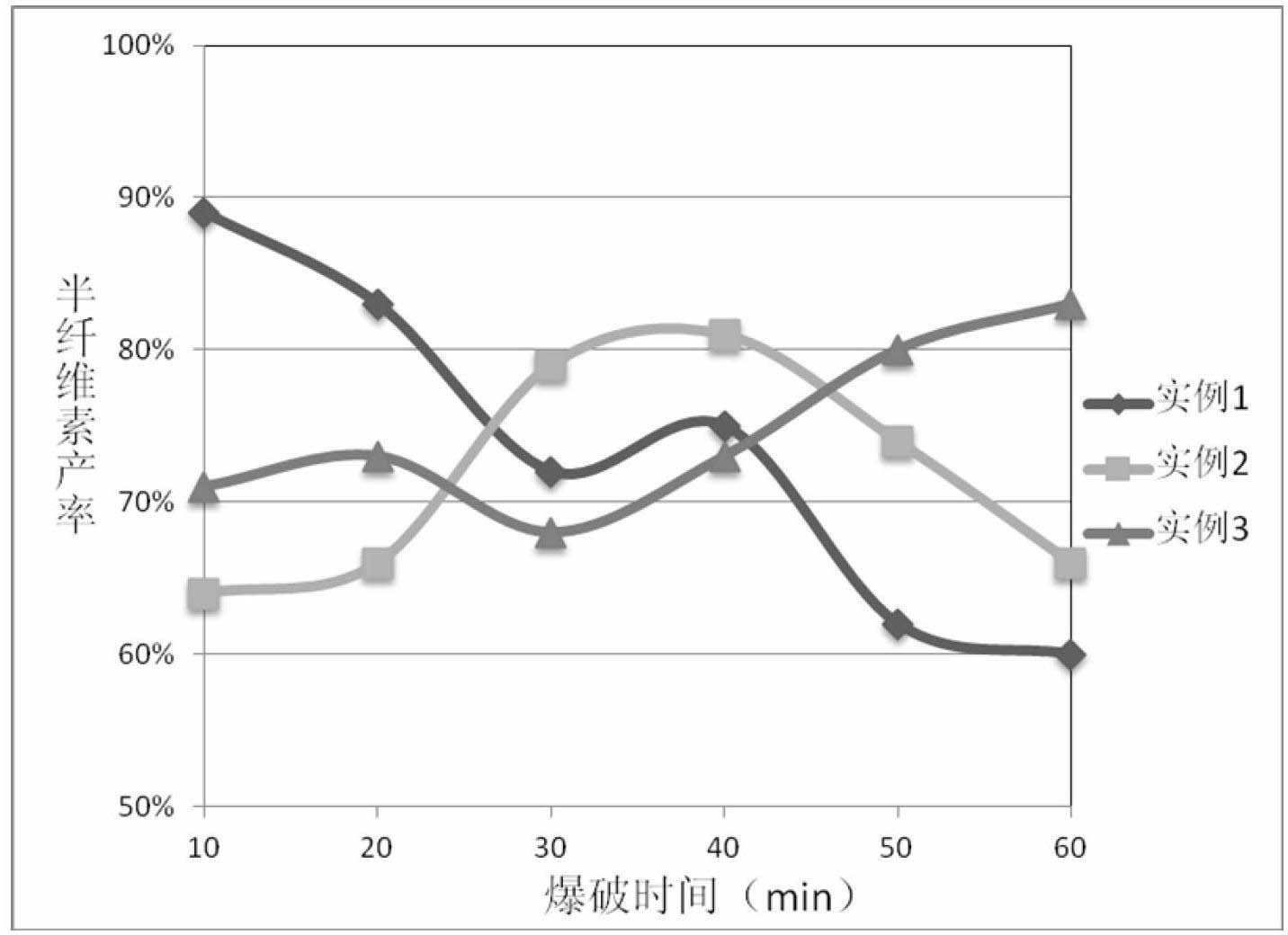

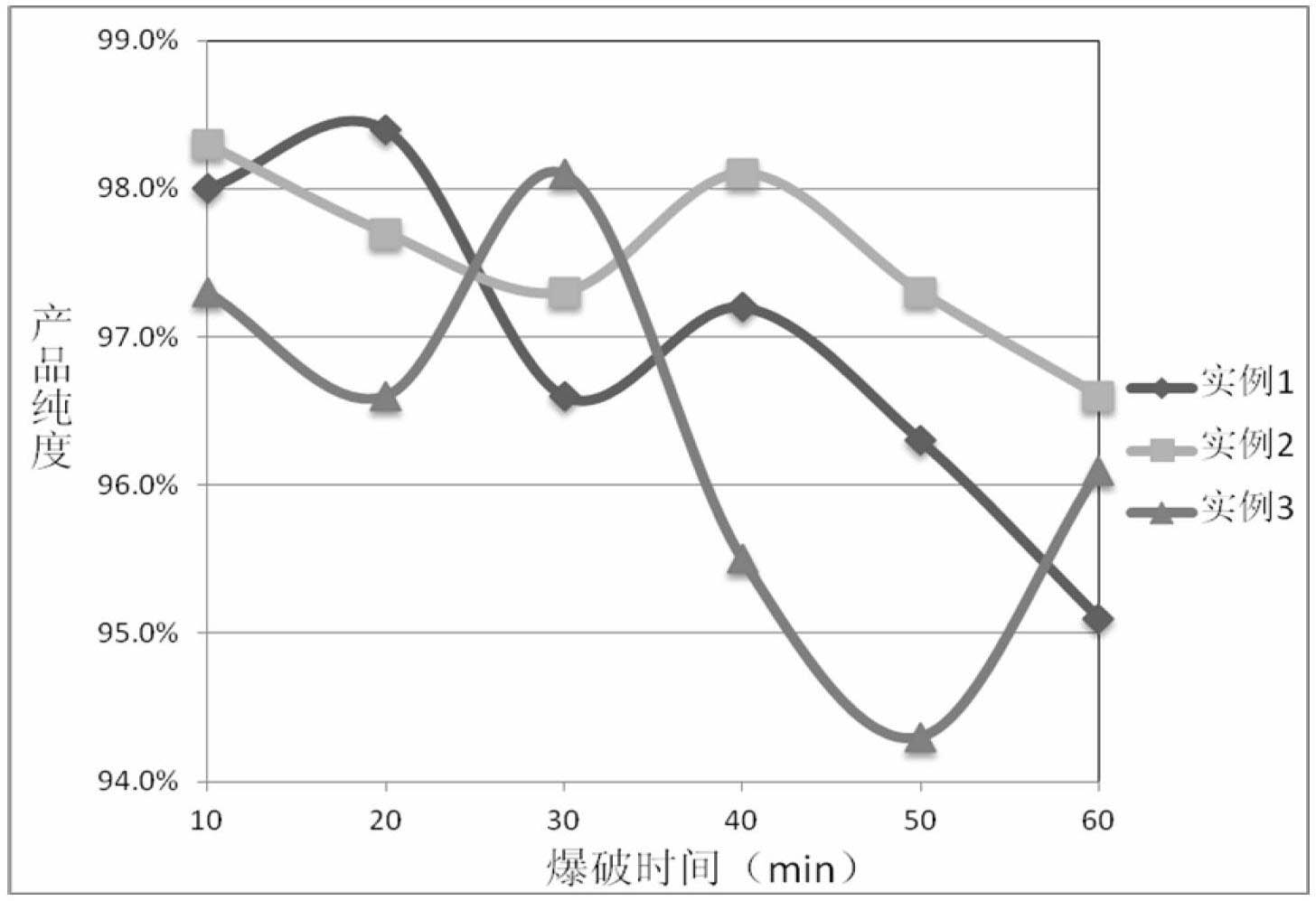

Embodiment 1

[0028] A method for producing hemicellulose by treating straw with ammonia steam explosion technology, the steps are as follows:

[0029] 1) Pulverize the straw into straw powder, the particle size is 100 mesh sieve;

[0030] 2) In the steam explosion reaction kettle, successively add straw scraps and ammonia solution with a concentration of 1% by weight, and the dosage ratio is 1g:15ml;

[0031] 3) Start the steam blaster, control the reaction temperature to 160°C, and hold the pressure at 0.6MPa for 10min before blasting;

[0032] 4) Take out the blasted material, filter it, dry it, and then seal it for storage, so as to obtain the pretreated straw raw material;

[0033] 5) Mix the pretreated straw raw material and the NaOH solution with a concentration of 10% by weight evenly, and the dosage ratio is 1g:75ml to obtain a mixture;

[0034] 6) The above mixture was reacted at a temperature of 50 °C for 2 hours, and the filtrate was obtained after filtration;

[0035] 7) The...

Embodiment 2

[0039] A method for producing hemicellulose by treating straw with ammonia steam explosion technology, the steps are as follows:

[0040] 1) Pulverize the straw into straw powder, the particle size is 100 mesh sieve;

[0041] 2) In the steam explosion reaction kettle, successively add straw scraps and ammonia solution with a concentration of 10% by weight, and the dosage ratio is 1g:150ml;

[0042] 3) Start the steam blaster, control the reaction temperature to 140°C, hold the pressure at 0.4MPa for 40min and then blast;

[0043] 4) Take out the blasted material, filter it, dry it, and then seal it for storage, so as to obtain the pretreated straw raw material;

[0044] 5) Mix the pretreated straw raw material and the NaOH solution with a concentration of 5% by weight evenly, and the dosage ratio is 1g:50ml to obtain a mixture;

[0045] 6) The above mixture was reacted at 90°C for 2h, and the filtrate was obtained after filtration;

[0046] 7) The filtrate obtained by filtr...

Embodiment 3

[0050] A method for producing hemicellulose by treating straw with ammonia steam explosion technology, the steps are as follows:

[0051] 1) Pulverize the straw into straw powder, the particle size is 100 mesh sieve;

[0052] 2) In the steam explosion reaction kettle, successively add straw scraps and ammonia solution with a concentration of 1% by weight, and the dosage ratio is 1g:100ml;

[0053] 3) Start the steam blaster, control the reaction temperature to 140°C, hold the pressure at 0.4MPa for 60min and then blast;

[0054] 4) Take out the blasted material, filter it, dry it, and then seal it for storage, so as to obtain the pretreated straw raw material;

[0055] 5) Mix the pretreated straw raw material and the NaOH solution with a concentration of 25% by weight evenly to obtain a mixture;

[0056] 6) The above mixture was reacted at a temperature of 40°C for 2 hours, and the filtrate was obtained after filtration;

[0057] 7) Adjust the pH of the filtrate obtained by f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com