Method for realizing seismic reinforcement of pier by the aid of carbon fibers

A carbon fiber and carbon fiber cloth technology, used in bridge reinforcement, bridges, bridge parts, etc., can solve the problems of imperfect improvement of the overall mechanical performance of the structure, complicated process construction, etc., and achieve remarkable reinforcement effect, simple construction process, and ideal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

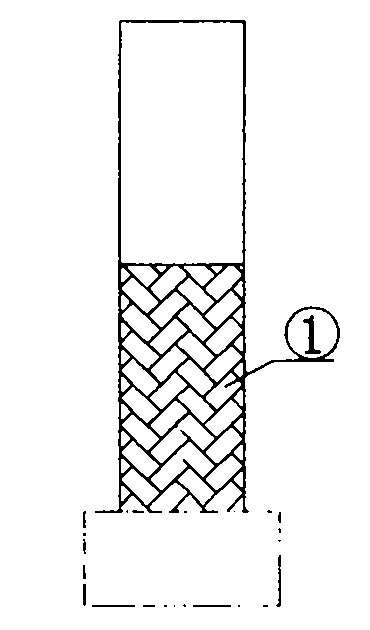

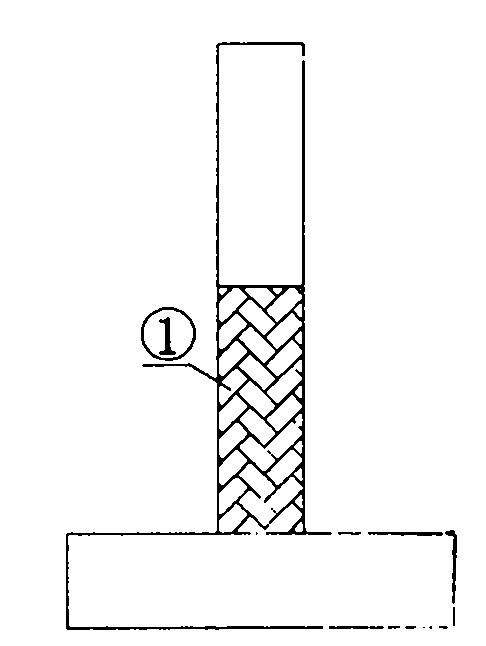

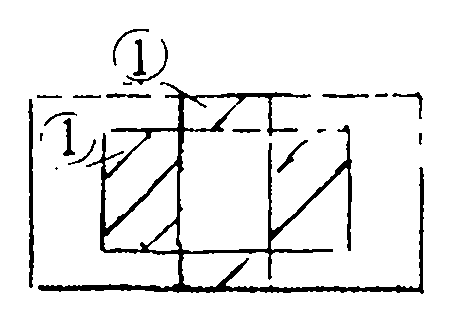

[0026] A method of carbon fiber seismically reinforced bridge pier, comprising:

[0027] ① Pier body surface treatment

[0028] Grind and smooth the surface of the pier where carbon fiber is to be pasted. Determine the scope of reinforcement according to the seismic design code. Within the scope of reinforcement, if there are large unevenness on the surface or wide cracks, it should be filled with high-strength mortar containing fibers. In the case of concrete crushing at the root of the pier, the Smash the root concrete and fill it with high-strength mortar. If it is a rectangular pier, the four corners should be ground into 2-3cm rounded corners to facilitate the sticking and force bearing of carbon fiber cloth. And ensure a minimum 20cm overlap length of carbon fiber cloth on the surface of the platform to ensure that the carbon fiber at the root will not peel off under load

[0029] ② Brush primer

[0030] After the surface treatment of the pier body, a layer of primer...

experiment example

[0044] In the test, the pier before reinforcement had obvious cracks when it was loaded to 40KN, the concrete at the bottom of the pier was crushed at 80KN, and reached the ultimate horizontal bearing capacity at 91KN. If the bridge pier reinforced with carbon fiber cloth is loaded to 60KN, some carbon fibers will start to peel off, and the cap will have tiny cracks, and the maximum horizontal bearing capacity will reach 177KN. From Figure 5 The force-displacement skeleton curve diagram (dotted line is before reinforcement, and solid line is after reinforcement) can be seen: the present invention can obviously improve the seismic bearing capacity and the ductility of bridge piers.

[0045] Figure 6 is the force-displacement hysteretic curve of the unreinforced pier, Figure 7 is the force-displacement hysteresis curve of the reinforced pier. Figure 6 and Figure 7 From the comparison, it can be clearly seen that the force-displacement hysteresis curve of the reinforced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com