Heat flow simulation test device of crystallizer meniscus horizontal heat transfer

A heat transfer heat flow and simulation test technology is applied in the field of a mold meniscus horizontal heat transfer heat flow simulation test device to achieve the effects of accurate and controllable shell temperature, low manufacturing cost, and convenient equipment use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

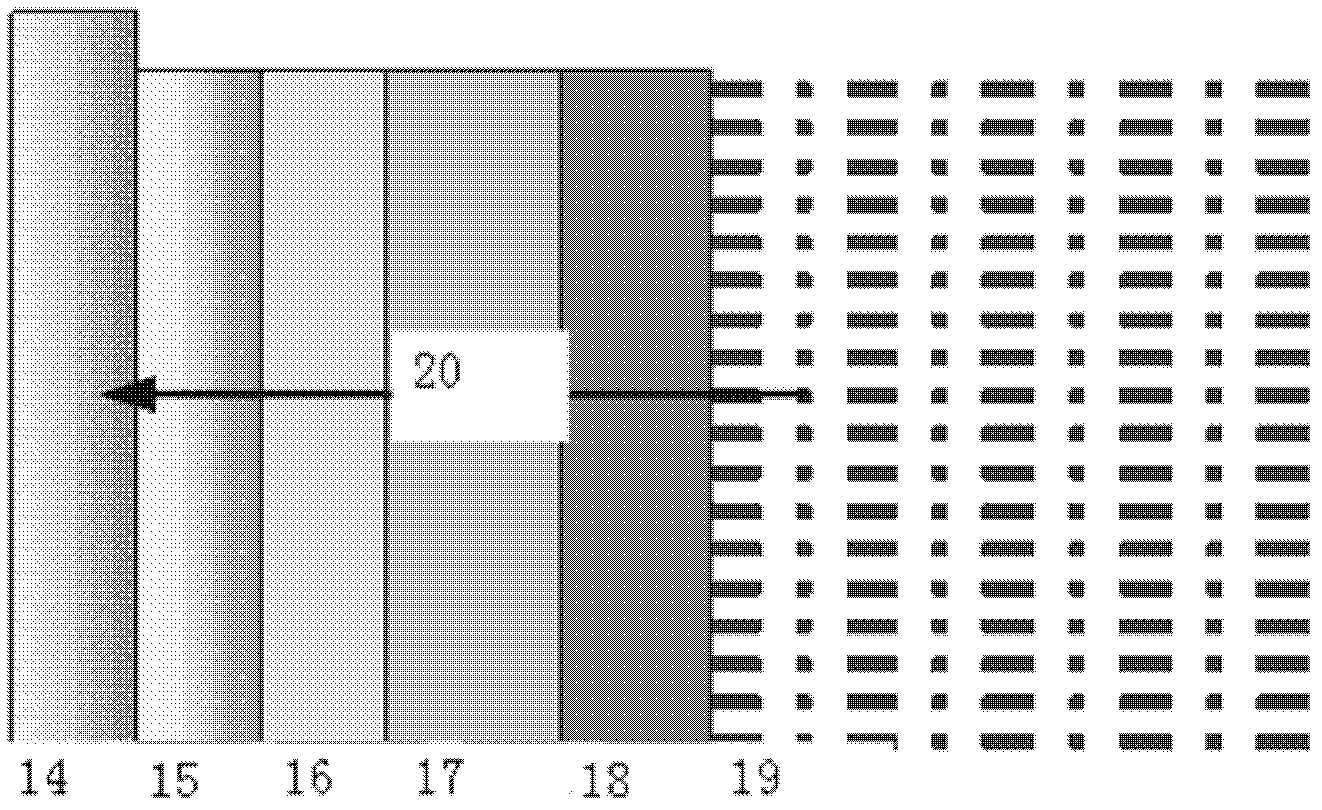

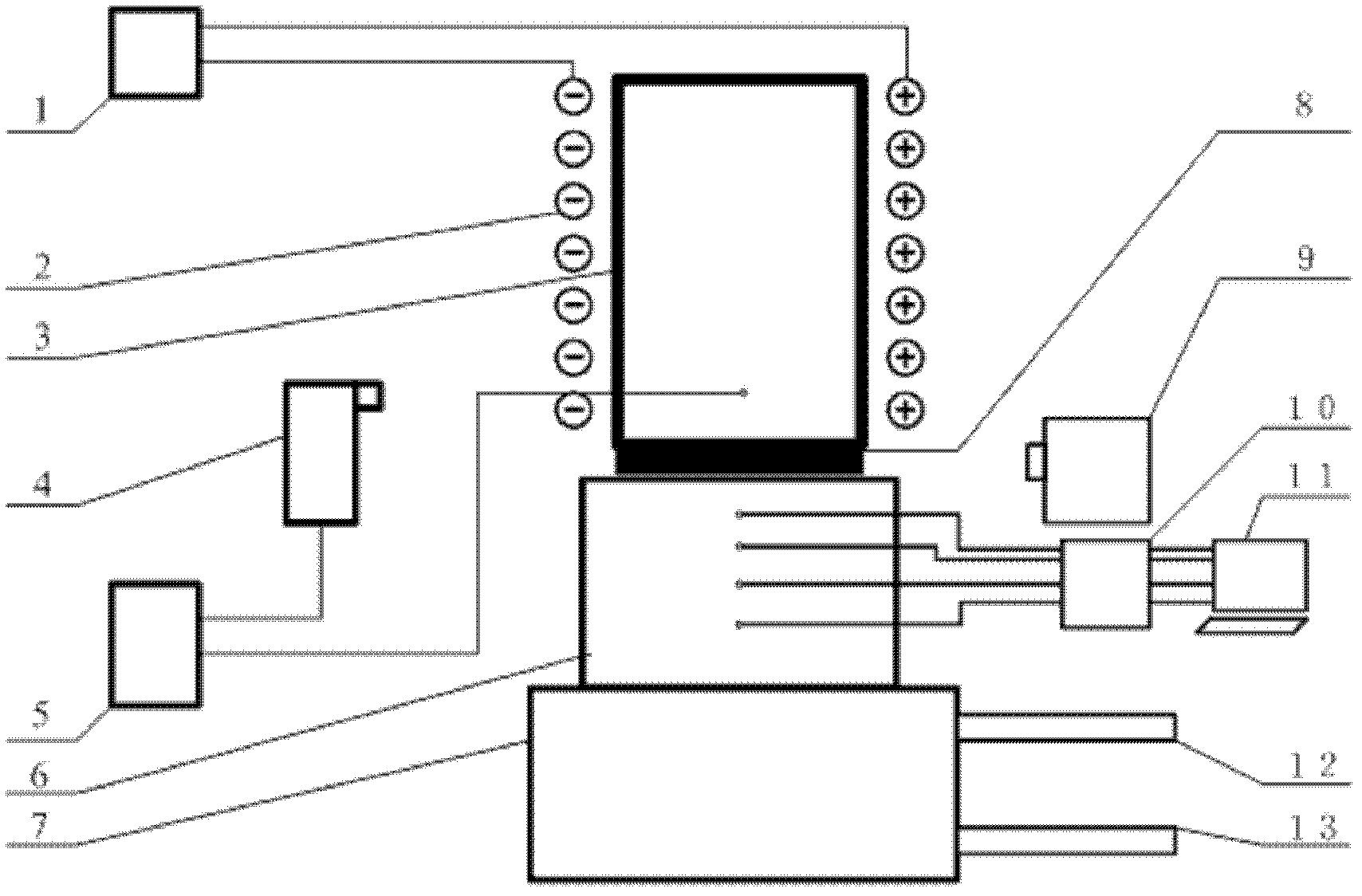

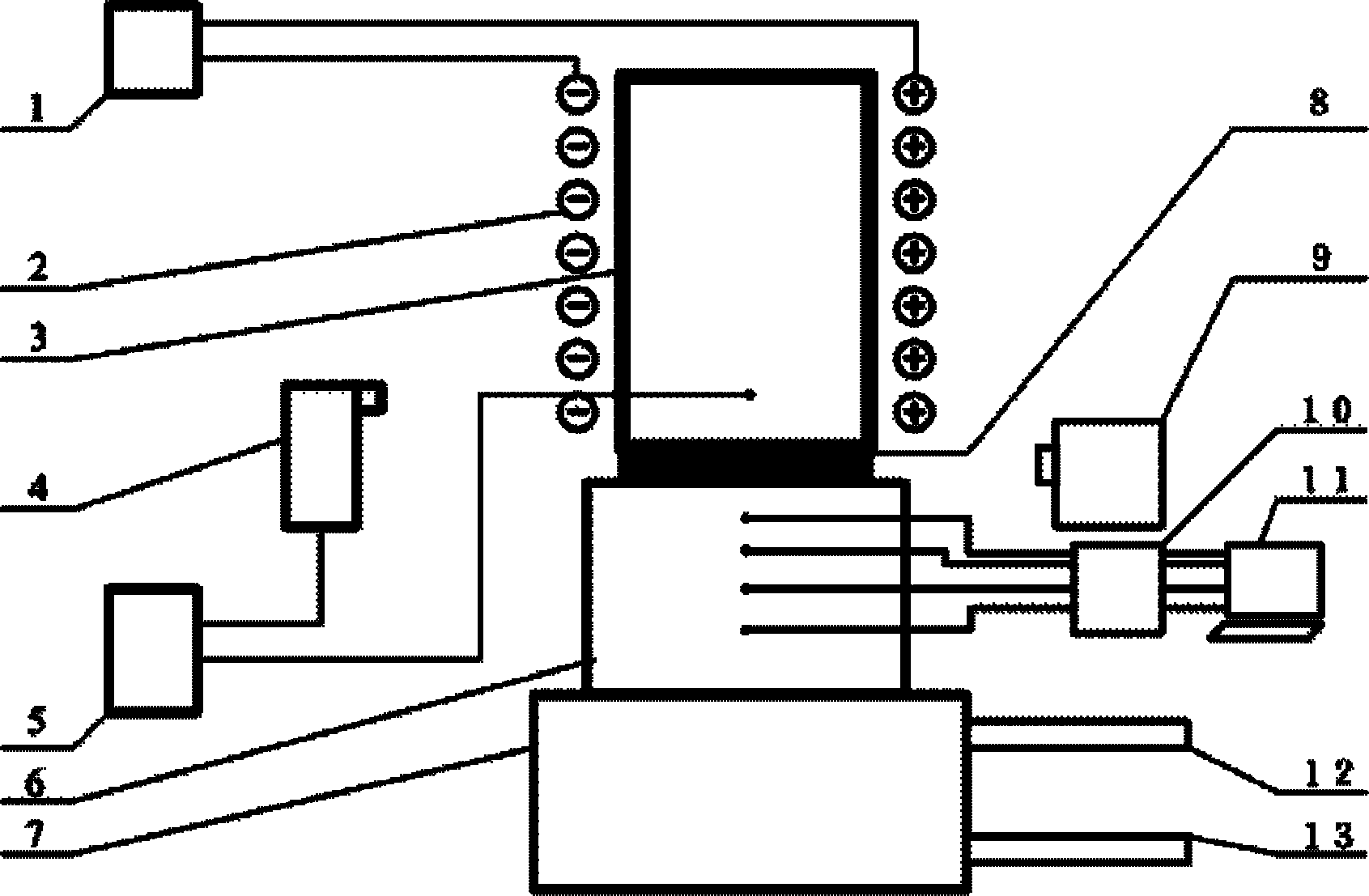

[0013] Such as figure 2 As shown, an embodiment of the present invention includes a blank shell 3, a crystallizer 6, a computer 11, a base 7, two temperature collectors 4 and 10, two temperature control modules 1 and 5, and the crystallizer 6 is fixed on the base 7, The mold shell 3 is fixed above the mold 6, and a mold slag sample 8 is fixed between the mold 6 and the mold shell 3. A camera 9 is installed on one side of the mold slag sample 8, and an induction heating coil 2 is installed on both sides of the mold shell 3. The heating coil 2 is connected to the first temperature control module 1, the thermocouple is inserted in the blank shell 3 and the crystallizer 6, and the second temperature control module 5 is respectively connected to the thermocouple in the blank shell 3 and the first temperature collector 4 Connection, the thermocouple in the crystallizer 6 is connected with the computer 11 through the second temperature collector 10, and the base 7 is provided with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com