Silver-tin eutectic thin film solder with copper thin layer introduced and preparation method of silver-tin eutectic thin film solder

A thin-layer and thin-film technology, which is applied in the field of silver-tin eutectic thin-film solder and preparation, can solve the problems that the electrical and thermal properties are difficult to adapt to the development trend of packaging technology, the reliability of solder joints is reduced, and the reliability of solder joints is poor. Reliability and solderability, low cost, and defect reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Substrate cleaning

[0027] For 6061 aluminum alloy as the substrate material, it was first ultrasonically cleaned in absolute ethanol at 50 Hz for 10 min, then rinsed with deionized water and dried, and then divided into two groups.

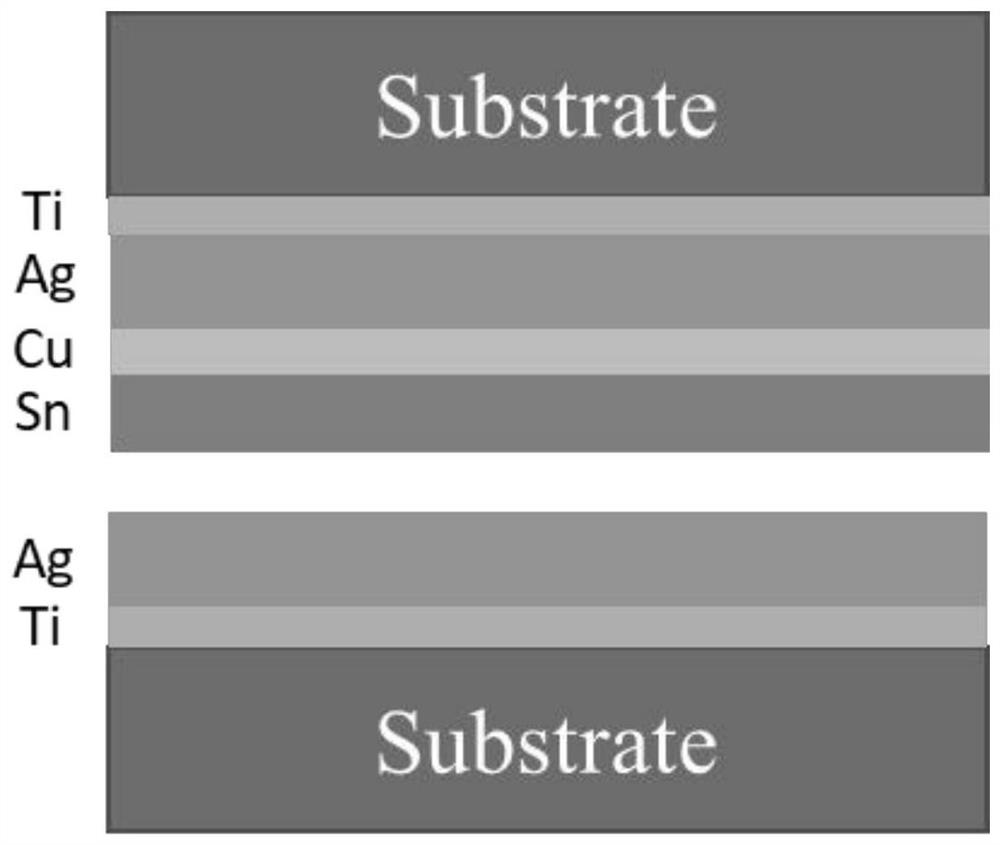

[0028] Step 2: Vacuum magnetron sputtering deposition process

[0029] The background vacuum in the magnetron sputtering chamber is 3.0×10 -4 Pa, 20sccm of Ar was introduced, and the working pressure was controlled to be 0.2Pa. Before deposition, the target was pre-sputtered for 10 minutes, and then a group of substrate materials were placed into the sputtering chamber. The DC sputtering power used for silver and copper targets The tin target is 100W, the tin target adopts RF sputtering power of 50W, and the substrate is biased at -50V, and deposits about 1μm silver, 20nm copper and 1μm tin successively. After the deposition is completed, the substrate material is taken out and placed into another set of substrate materials. Dep...

Embodiment 2

[0033] Step 1: Substrate cleaning

[0034] For 6061 aluminum alloy as the substrate material, it was first ultrasonically cleaned in absolute ethanol at 50 Hz for 10 min, then rinsed with deionized water and dried, and then divided into two groups.

[0035] Step 2: Vacuum magnetron sputtering deposition process

[0036] The background vacuum in the magnetron sputtering chamber is 3.0×10 -4 Pa, 30sccm of Ar was introduced, and the working pressure was controlled to be 0.3Pa. Before deposition, the target was pre-sputtered for 10 minutes, and then a group of substrate materials were placed into the sputtering chamber. The silver and copper targets were sputtered by DC sputtering. The power is 130W, the tin target adopts radio frequency sputtering power of 70W, and the substrate is biased at -60V. About 1.5μm silver, 200nm copper and 2μm tin are deposited successively. After the deposition is completed, the substrate material is taken out and placed into another set of substrate...

Embodiment 3

[0040] Step 1: Substrate cleaning

[0041] For SiC ceramics as the substrate material, they were first ultrasonically cleaned in absolute ethanol at 50 Hz for 10 min, then rinsed with deionized water and dried, and then divided into two groups.

[0042] Step 2: Vacuum magnetron sputtering deposition process

[0043] The background vacuum in the magnetron sputtering chamber is 3.0×10 -4 Pa, 40sccm of Ar was introduced, and the working pressure was controlled to be 0.4Pa. Before deposition, the target was pre-sputtered for 10 minutes, and then a group of substrate materials were placed into the sputtering chamber. The silver and copper targets were sputtered by direct current The power is 160W, the tin target adopts radio frequency sputtering power of 120W, the substrate is biased at -80V, and about 2μm silver, 300nm copper and 1.5μm tin are deposited successively. After the deposition is completed, the substrate material is taken out and placed into another set of substrate ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com