Continuous-casting casting powder comprehensive heat transfer heat flow testing method

A technology for continuous casting mold flux and heat transfer heat flow, which is applied in calorimeters, measuring devices, measuring heat and other directions to achieve the effects of high data accuracy, convenient preparation, and accurate and controllable temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

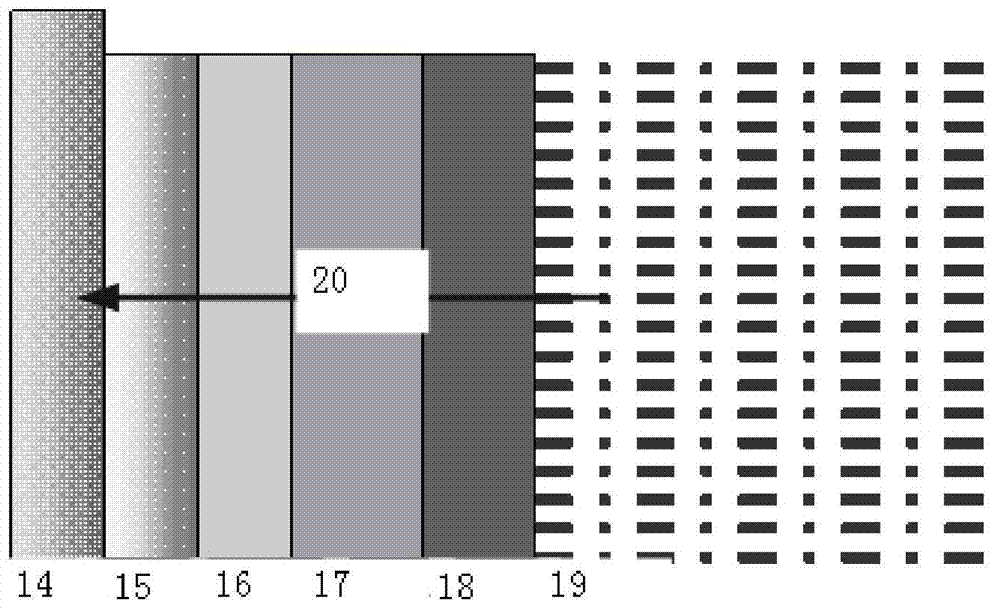

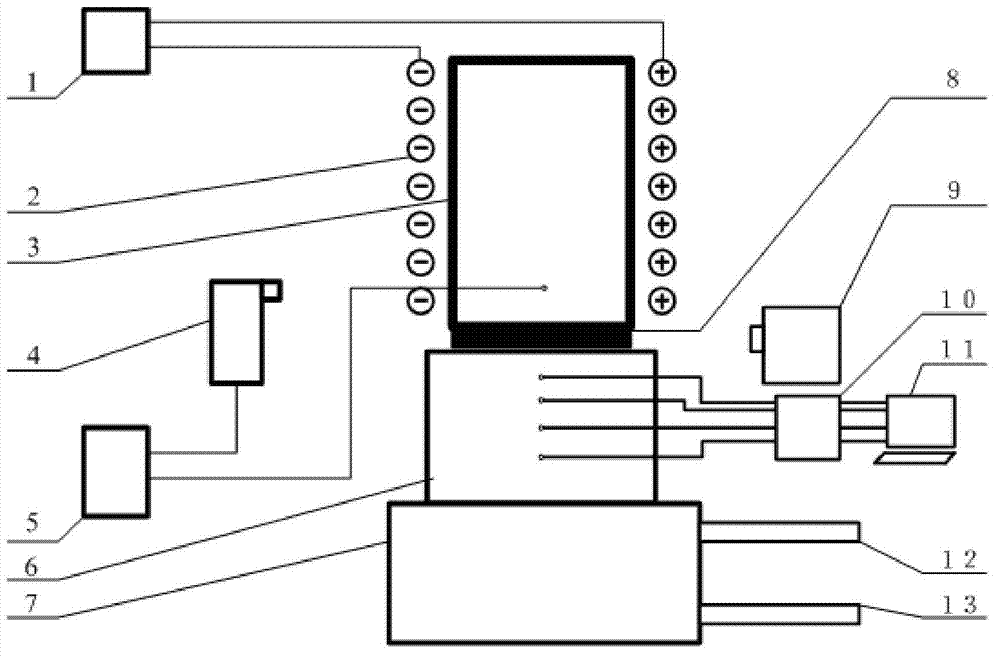

[0018] Such as figure 1 As shown, the heat transfer and heat flow simulation test device of an embodiment of the present invention includes a blank shell 3, a copper mold crystallizer 6, a computer 11, a base 7, two temperature collectors 4 and 10, two temperature control modules 1 and 5, copper The mold mold 6 is fixed on the base 7, the base shell 3 is fixed above the copper mold mold 6, a mold slag sample 8 is fixed between the copper mold mold 6 and the blank shell 3, and a camera 9 is installed on one side of the mold slag sample 8 The two sides of the billet shell 3 are provided with an induction furnace 2, the induction furnace 2 is connected to the first temperature control module 1, a thermocouple is inserted in the billet shell 3 and the copper mold crystallizer 6, and the second temperature control module 5 is respectively connected to the billet The thermocouple in the shell 3 is connected to the first temperature collector 4, the thermocouple in the copper mold cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com