Power semiconductor module adopting double-sided cooling

A power semiconductor, double-sided cooling technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as difficult double-sided cooling, and no substrate design scheme for double-sided cooling, etc. Achieve the effects of improving reliability, excellent thermal management ability, and increasing flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The power semiconductor module in the embodiment of the present invention is a circuit structure in the form of a half bridge.

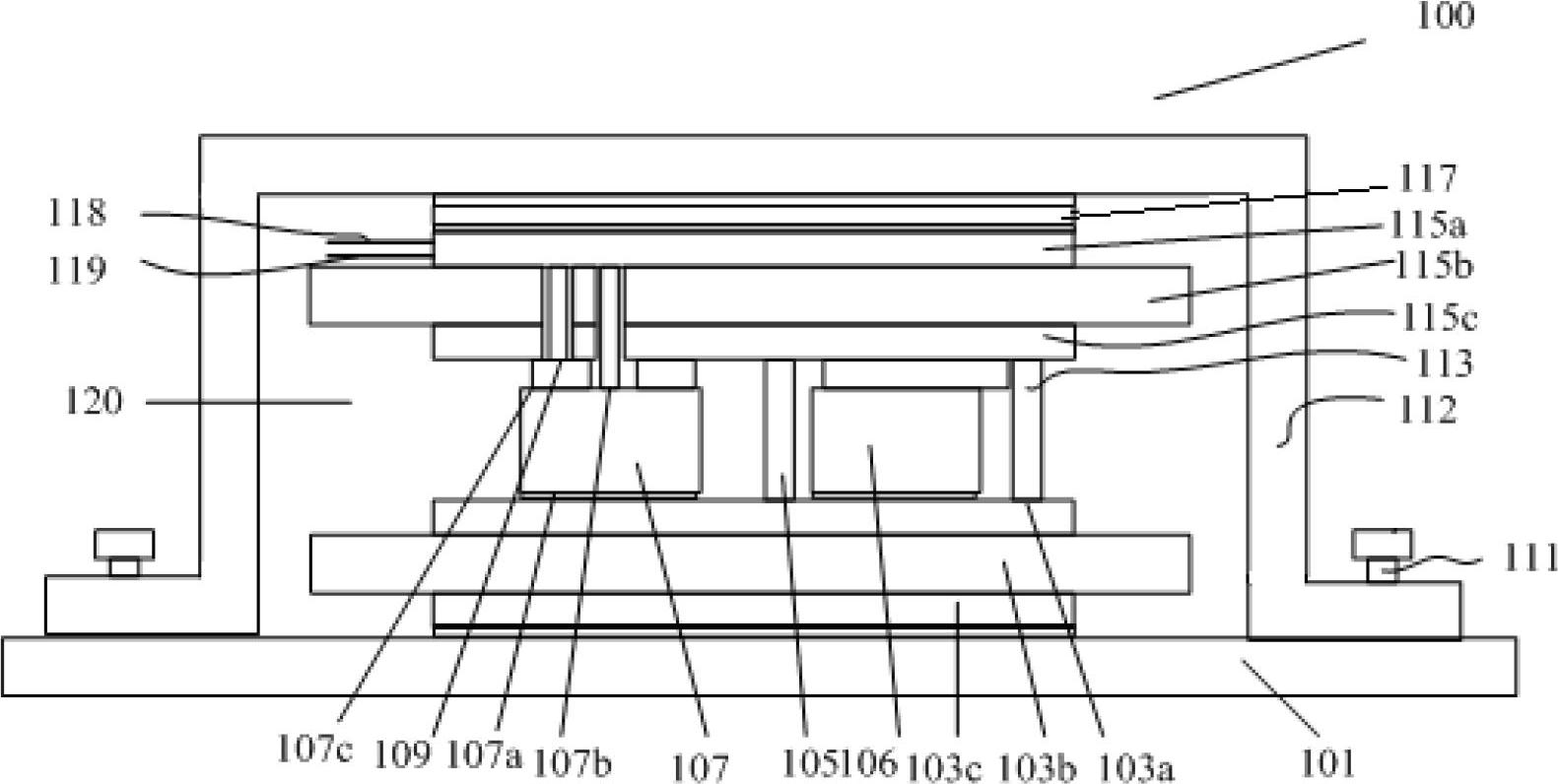

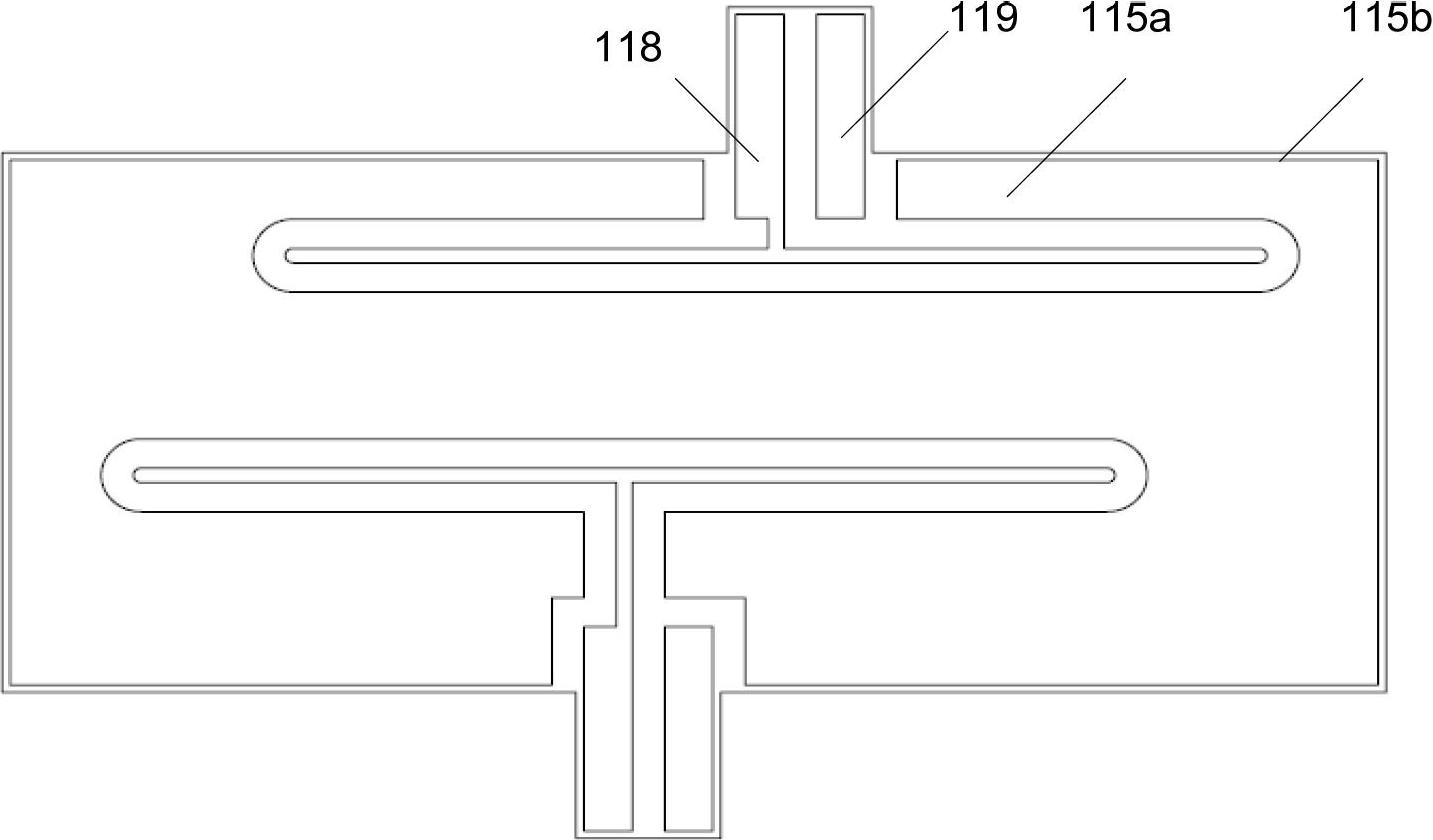

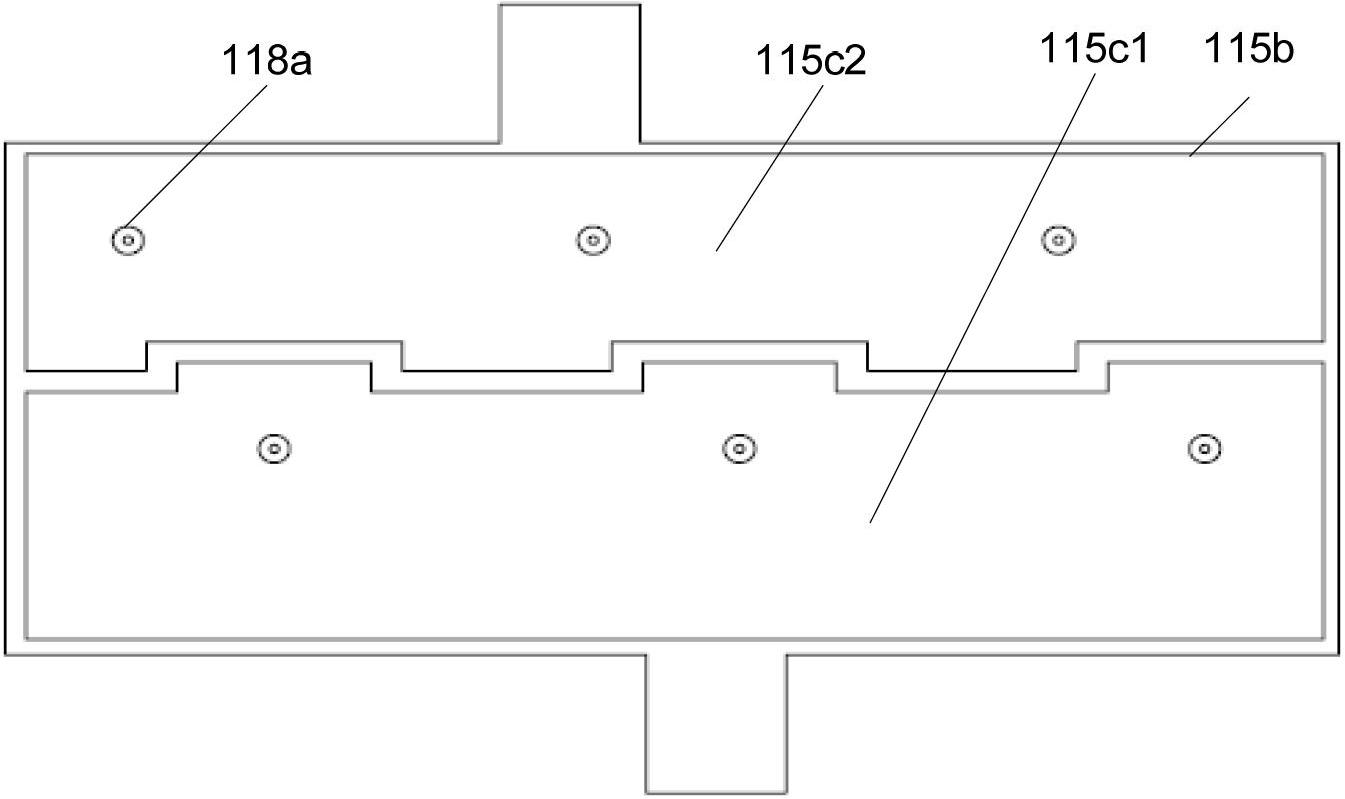

[0028] figure 1 and Figure 7 The power semiconductor module 100 shown is composed of power semiconductor chips 106, 107, substrates 103, 115 cooling plates 101, 112, insulating layer 117, positive terminal 121, negative terminal 123, AC output terminal 122, grid lead-out terminal 118, and The emitter lead-out terminal 119 is formed. The power semiconductor chip includes a fully-controlled power semiconductor chip 107 and an anti-parallel uncontrolled power semiconductor chip 106, and the fully-controlled power semiconductor chip 107 and anti-parallel uncontrolled power semiconductor chip 106 are located in the second between the substrate 103 and the first substrate 115 . Among the two substrates, the first substrate is composed of the first metal layer 115a, the first insulating layer 115b and the second metal layer 115c; the second subst...

Embodiment 2

[0036] Figure 8 to Figure 11 Shown is an embodiment of the second half-bridge structure composed of power semiconductor modules according to the present invention.

[0037] Figure 8 The power semiconductor module 200 shown is composed of power semiconductor chips 205, 206, substrates 203, 215, cooling plates 201, 212, positive terminal 221, negative terminal 223, AC output terminal 222, gate lead-out terminal 218, and emitter lead-out terminal 219 compositions. The power semiconductor chip includes a fully controlled power semiconductor chip 205 and an anti-parallel uncontrolled power semiconductor chip 206 . The full-controlled power semiconductor chip 205 and the anti-parallel uncontrolled power semiconductor chip 206 are located between the first substrate 215 and the second substrate 203 . Among the two substrates, the first substrate is composed of the first metal layer 215a, the first insulating layer 215b and the second metal layer 215c; the second substrate is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com