Water-cooled air atomizing spray gun suitable for denitration adopting SNCR method

An atomizing spray gun, cold air technology, applied in spray devices, separation methods, liquid spray devices and other directions, can solve the problems of unstable nozzle performance, short service life, poor reliability, etc., to achieve wide applicability and operability, Avoid high temperature corrosion and bonding, easy to replace and repair the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

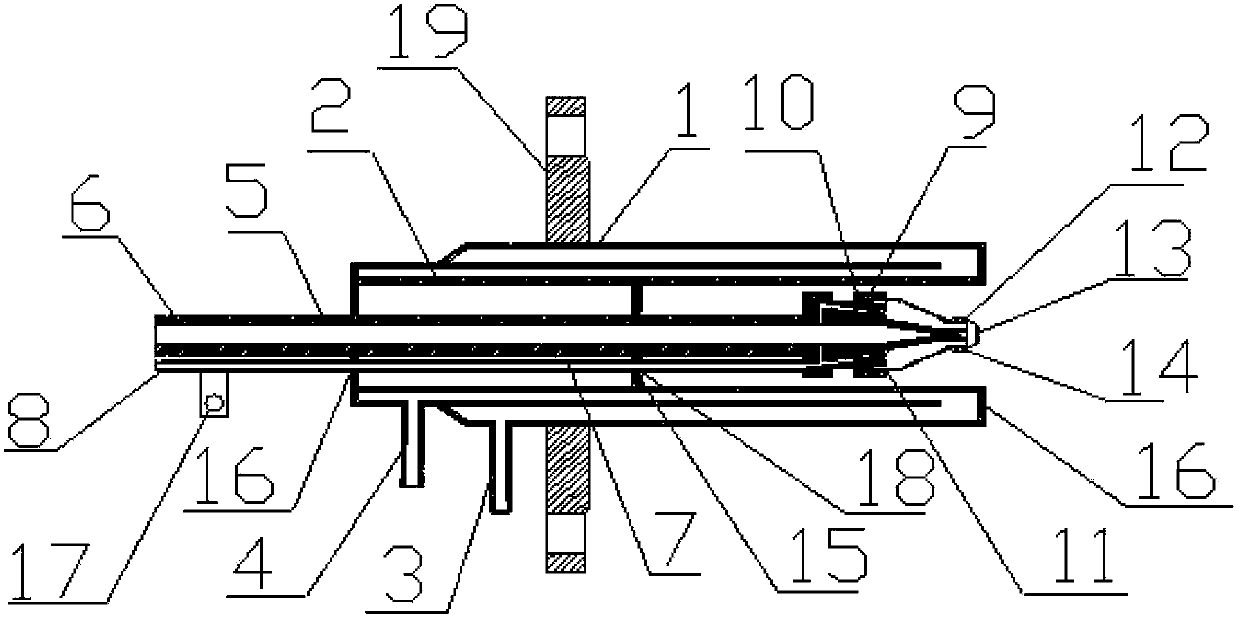

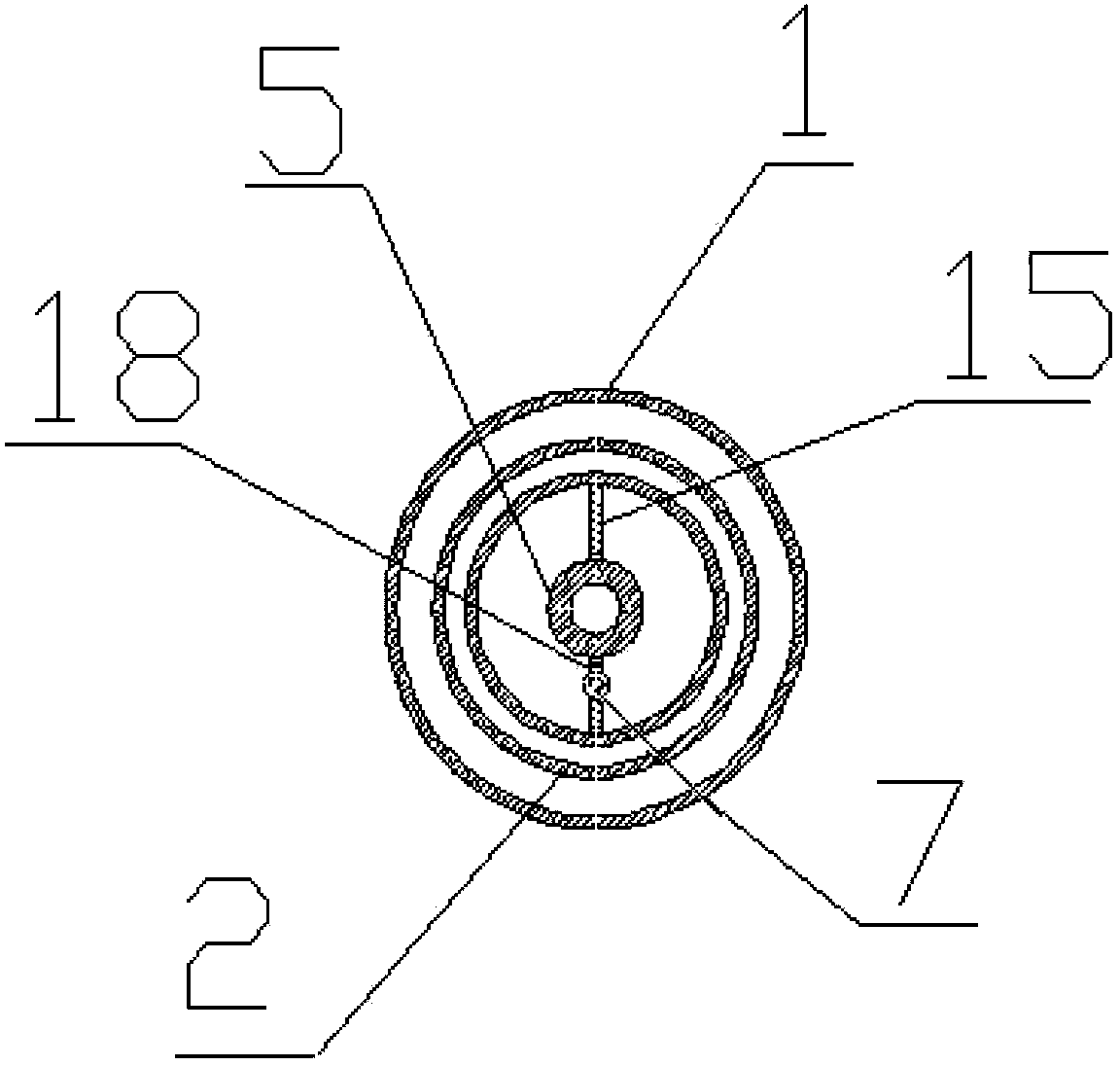

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] A water-cooled air atomization spray gun suitable for SNCR denitrification, including a spray gun body and a spray assembly, the spray gun body includes an outer sleeve 1, an inner sleeve 2, a cooling water inlet port 4, a cooling water outlet port 3, and a water pipe head 16 , supporting structure 15, supporting structure sealing gasket 18, kinematic connection mechanism 17 and fixed flange 19; the injection assembly includes aqueous solution pipe 5, aqueous solution pipe joint 6, air pipe 7, air pipe joint 8, nozzle joint 10, liquid cap 9, Liquid cap sealing gasket 11, air cap 12, air cap sealing gasket 14.

[0018] Outer casing 1 coated with high-temperature wear-resistant layer is provided with a fixed flange 19, the outer casing 1 and inner casing 2 are connected by welding, the inner casing 2 is provided with a cooling water inlet 4, and the outer casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com