Method for manufacturing composite prestress enhanced ceramic cylinder sleeve

A manufacturing method and prestressing technology, applied to cylinders, engine components, mechanical equipment, etc., can solve the problems of high processing accuracy, lower combustion chamber temperature, incompleteness, etc., achieve low processing accuracy requirements, and reduce heat dissipation loss , The effect of heat dissipation loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

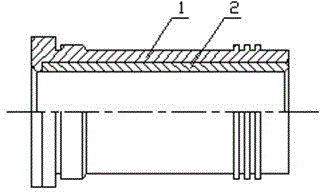

[0021] Embodiment 1: prepare as figure 1 The composite prestressed ceramic-lined cylinder liner shown has the following structure: it includes a metal outer shell 1 and a ceramic inner liner 2, and the ceramic inner liner 2 is cast in the metal outer shell 1; wherein, the wall thickness of the ceramic inner liner 2 is 5mm, and the ceramic inner liner 2 The material of the lining 2 is silicon nitride ceramics.

[0022] The preparation method of the above-mentioned composite prestressed reinforced ceramic liner liner specifically includes the following steps:

[0023] 1) The ceramic lining 2 is manufactured and processed by the manufacturing and processing method of industrial ceramics, so that the inner surface and size meet the requirements of the cylinder liner, the thickness is uniform, and the outer surface is smooth and clean;

[0024] 2) Make a molten metal casting sand mold and place the ceramic lining 2 in it so that the centerline of the ceramic lining coincides with ...

Embodiment 2

[0029] Embodiment 2: Prepare composite prestressed reinforced ceramic liner cylinder liner, the structure is: comprise metal outer shell 1 and ceramic inner liner 2, ceramic inner liner 2 is cast in metal outer shell 1; Wherein, the wall thickness of ceramic inner liner 2 is 10mm , the material is alumina ceramics.

[0030] The preparation method of the above-mentioned composite prestressed reinforced ceramic liner liner specifically includes the following steps:

[0031] 1) Manufacture and process the ceramic lining 2 so that its inner surface and size meet the requirements of the cylinder liner, with uniform thickness and smooth outer surface;

[0032] 2) Make a metal casting sand mold and place the ceramic lining 2 in it, and place the center position accurately;

[0033] 3) Heat the ceramic lining 2 to 900°C and wait for casting;

[0034] 4) Pour the molten metal from the casting port into the sand mold with the ceramic lining as the inner mold. The molten metal is coole...

Embodiment 3

[0037] Embodiment 3: basically the same as Embodiment 1, the difference is the requirements of the ceramic lining and the temperature for heating the ceramic lining in step 3) during preparation;

[0038] Among them, the ceramic lining is made of silicon oxide ceramics, and its wall thickness is 8mm;

[0039] During preparation, in step 3), the ceramic lining is heated to 800°C and then cast.

[0040] Compared with similar models, the invention can reduce the heat dissipation loss of the cylinder liner by 20%, increase the temperature of the combustion chamber of the cylinder by 200°C, and increase the heat engine efficiency by 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com