Processing device for preventing inner plastic bag electrostatic adsorption

An adsorption treatment, plastic technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of filling failure, opening of plastic bags, wrong filling of materials, etc., and achieve the effect of fast filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

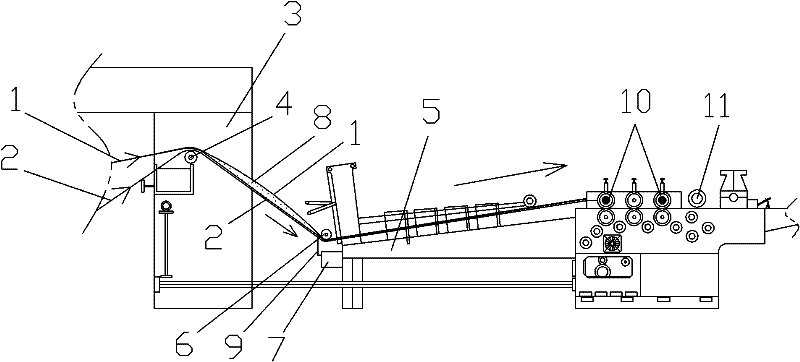

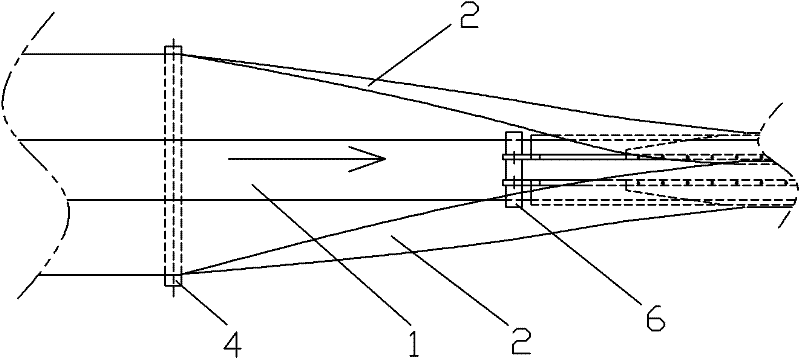

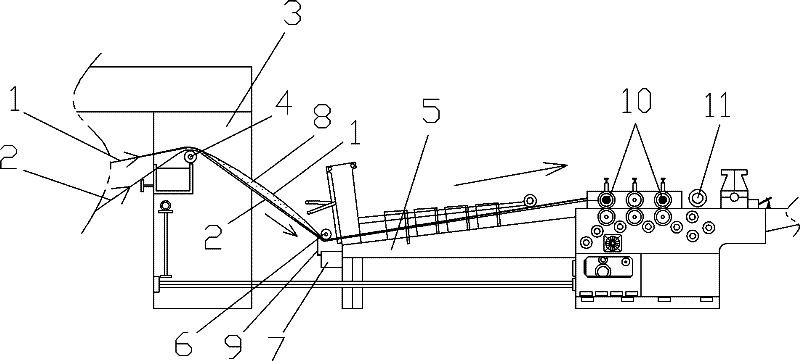

[0010] Such as figure 1 with figure 2 As shown, the anti-plastic inner bag adsorption treatment device of the present invention includes a combined stacking workstation 3, a combined stacking roll 4, a forming mechanism 5, a guide roll 6, a cylinder 7, an air gun 9, a traction roll 10, and a cutting knife 11. The inner bag 1 and paper 2 are installed on the bag making equipment, and are transported from unwinding, layering, dispensing and other mechanisms all the way to the upper figure 1 Combination superimposition workstation 3, combination superposition roller 4 is installed on the vertical wall of combination superposition workstation 3, forming mechanism 5 is installed in the rear of combination superposition workstation 3, and this forming mechanism 5 is to roll the flat paper into the specified widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com