Active energy ray curable transfer sheet and manufacturing method thereof

An active energy ray, curable technology, applied in chemical instruments and methods, temperature recording methods, coatings, etc., can solve the problem of unknown active energy ray curable transfer sheets, etc., to improve blocking resistance, improve no sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

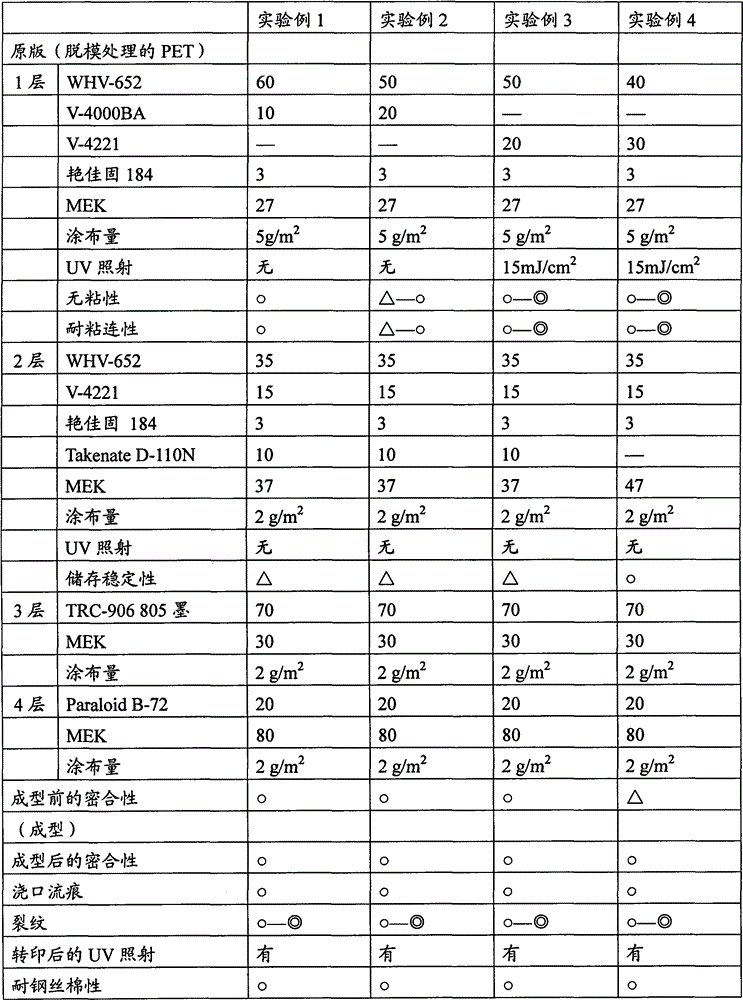

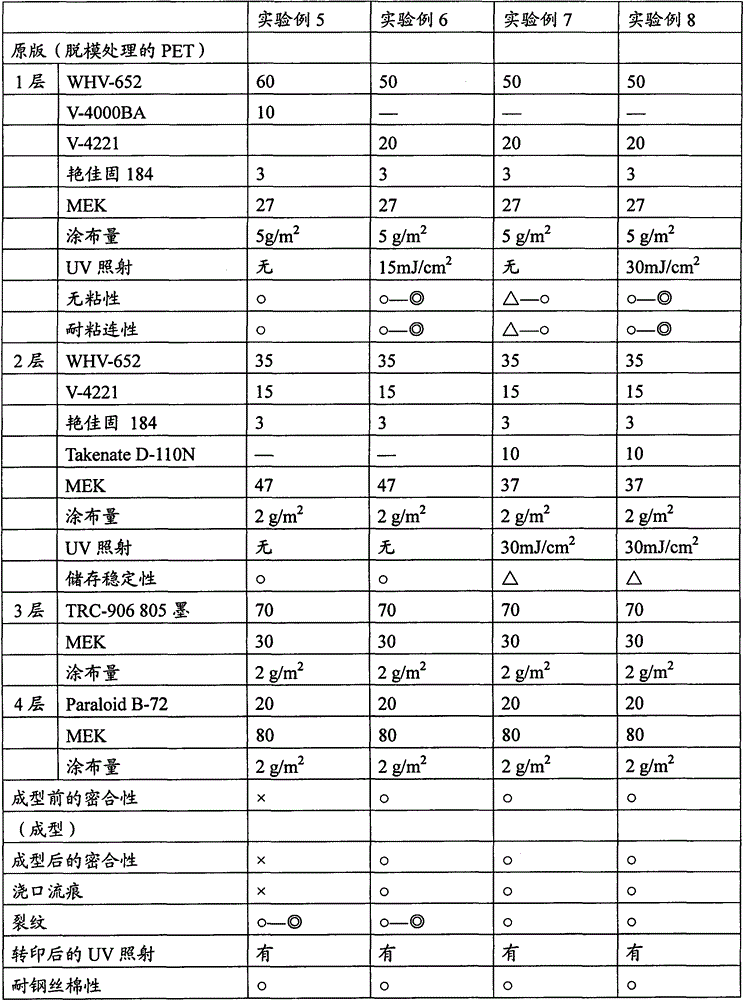

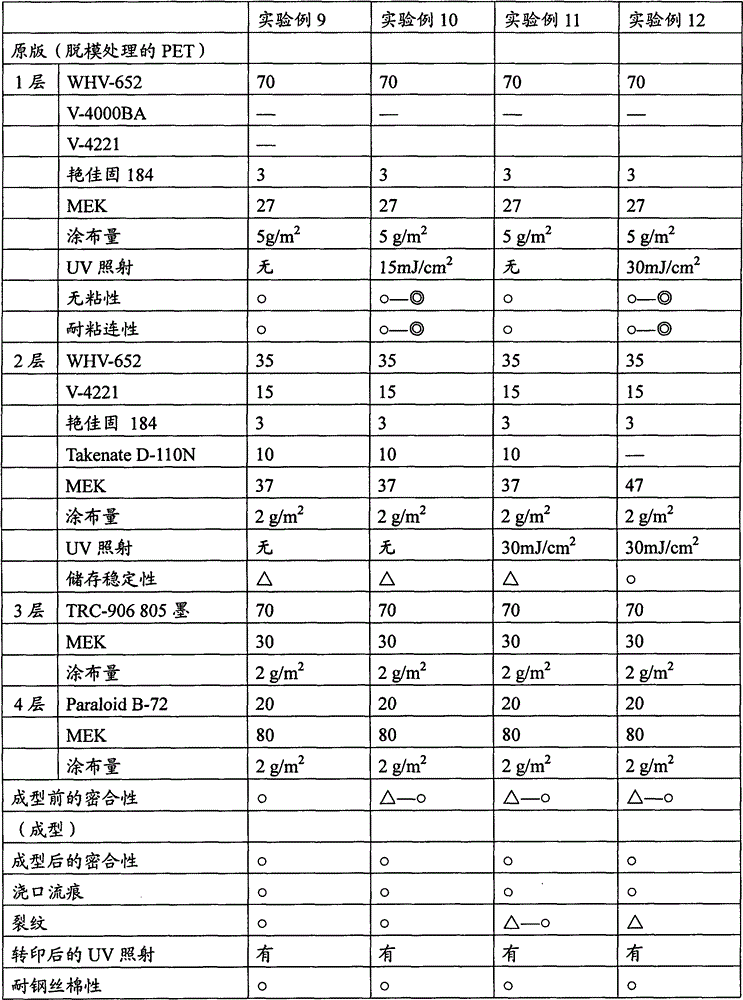

[0073] Next, the present invention will be described more specifically with reference to experimental examples. In addition, unless otherwise specified in this specification, "part" and "%" are a mass basis. Table 1 shows the coating film compositions and evaluation results of Examples and Comparative Examples.

[0074] (Preparation of Hard Coat Composition (1))

[0075] 60 parts of acrylic acrylate resin (WHV-652: produced by DIC company), 10 parts of urethane acrylate resin (UnidicV-4000BA: produced by DIC company), polymerization initiator (Yanjiagu 184: produced by Ciba Specialty Chemical Co., Ltd. 3 parts of preparation) and 27 parts of methyl ethyl ketone were mixed and stirred with a mixer to prepare the hard coating composition (1).

[0076] Here, WHV-652 produced by DIC Company has an acrylic acid double bond equivalent of 200-2500g / eq, a weight-average molecular weight of 50000-250000, a glass transition temperature of 40-130°C, and a hydroxyl value of 5-300 (mgKOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com