Method for treating acid wastewater of 2-methyl-4-chlorophenoxyacetic acid through extraction, neutralization and distillation integration

A technology of dimethyltetrachloric acid and acidic wastewater, which is applied in chemical instruments and methods, extraction water/sewage treatment, natural water treatment, etc., can solve problems such as unfavorable environmental protection, loss of useful substances, etc., and achieves reduction of wastewater volume and energy consumption. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

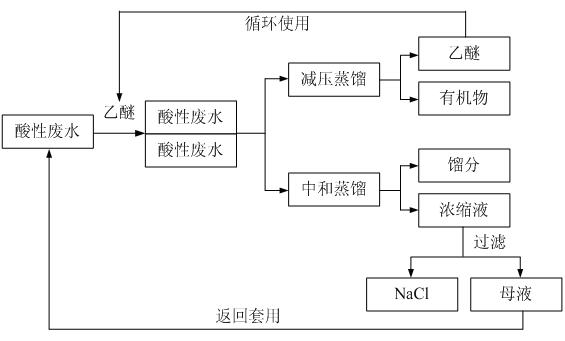

[0024] Embodiment 1, with reference to figure 1 As shown in the process flow chart, the raw material is the acidic wastewater in the production process of dimethyltetrachloride, which contains organic impurities and NaCl.

[0025] Take 250ml of raw acidic wastewater, and the extractant is 50ml of diethyl ether. Under normal temperature conditions, the acidic waste water is sent into the extractor and the inflowing extractant is fully stirred for liquid-liquid extraction, layered separation, and the extraction phase and the raffinate phase are in equilibrium. Take out the extract phase from the upper layer, distill under reduced pressure, collect ether, and use it as the next extractant recycling, and collect the remaining organic matters, whose weight accounts for about 0.4% of the total weight of the acidic wastewater. Add 1 g of NaOH to the lower aqueous phase and stir until neutral, then distill to concentrate the salt in the aqueous phase. After condensation, the distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com