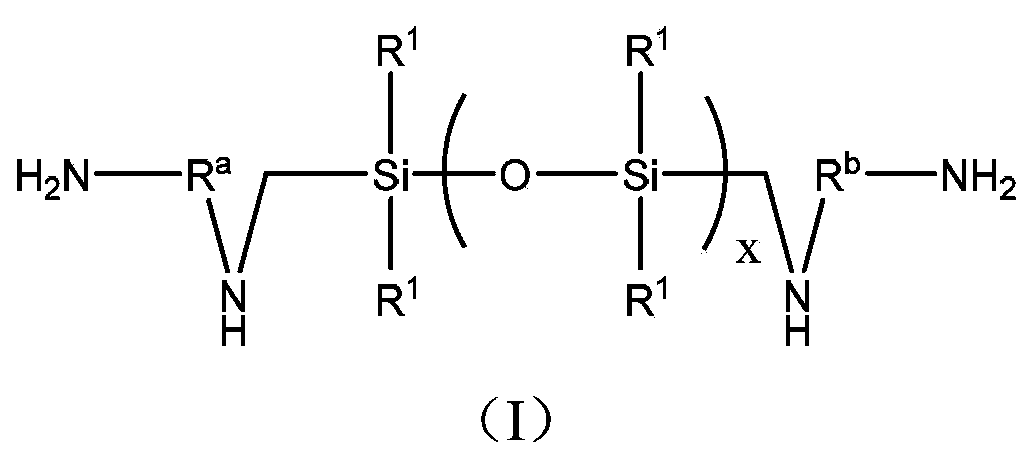

Organic silicon epoxy resin curing agent and epoxy curing system containing same

A technology of silicon epoxy resin and epoxy resin, which is applied in the field of epoxy curing system and silicone epoxy resin curing agent, can solve the problem of affecting the surrounding amino groups, large siloxane chain segments, and poor mechanical properties. Ideal and other issues, to achieve the effect of outstanding bonding performance and bending strength, wide application, and high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

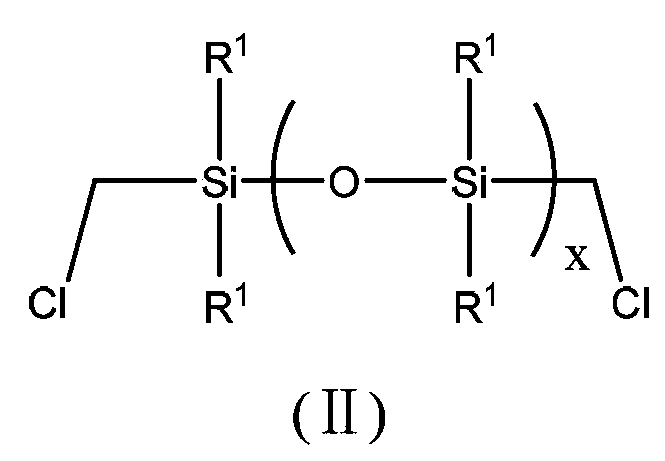

Problems solved by technology

Method used

Image

Examples

Embodiment 1

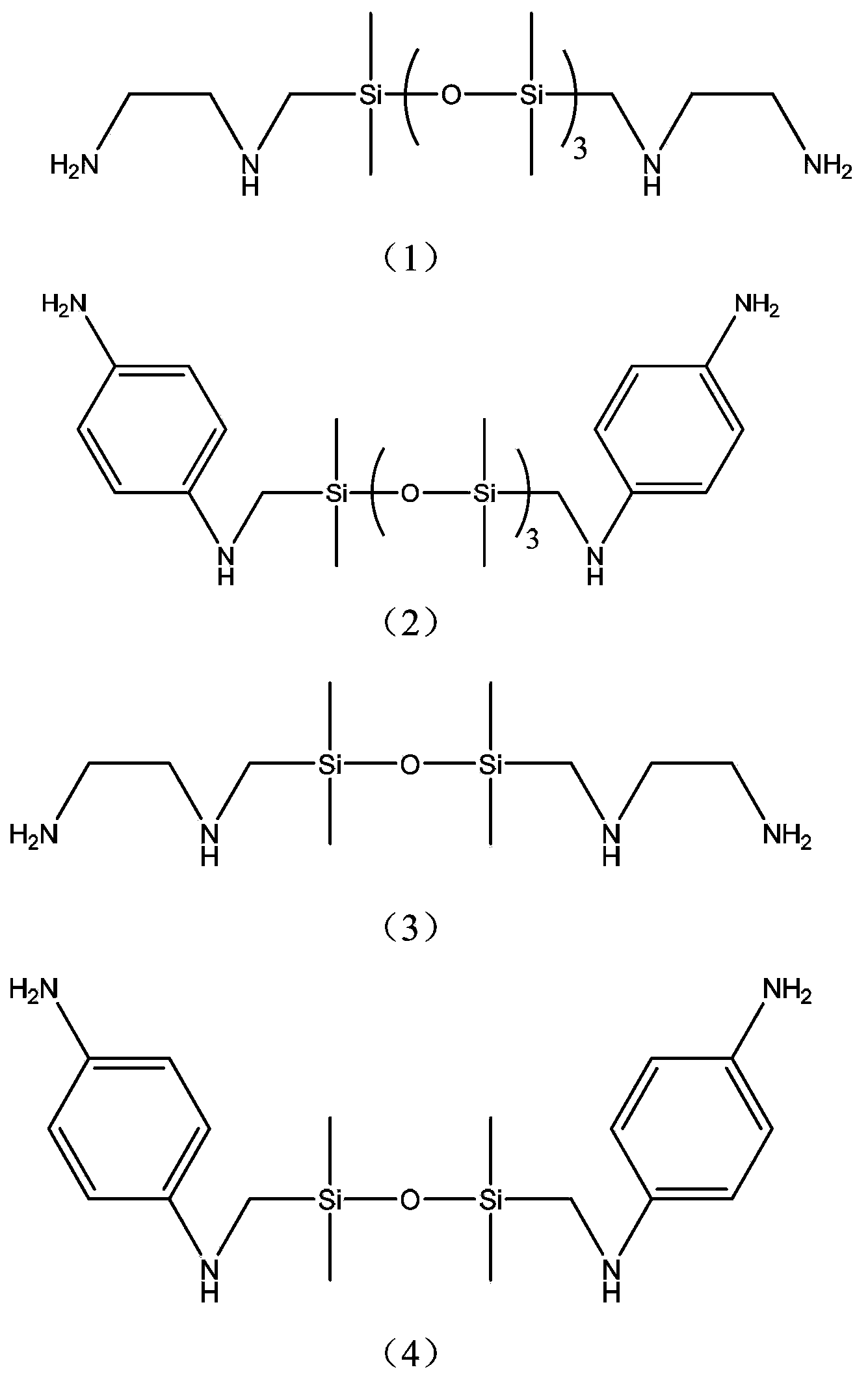

[0047] Using dichloromethyltetrasiloxane as raw material, it is directly added dropwise into ethylenediamine under stirring, the reaction temperature is controlled at 60-70°C, and the reaction time is 3h. After the reaction, the upper organic layer was separated and distilled under reduced pressure, and the fraction collected at 180-182° C. was the silicone epoxy resin curing agent represented by the above formula (1), with a yield of 93%.

[0048]Get 100 parts by weight of E-44 epoxy resin, 8 parts by weight of curing agent shown in formula (1), 0.4 parts by weight of 2-methylimidazole, stir for 1.5-2 hours and mix evenly, according to GB-T7124-1986 (adhesive tensile Shear strength test method) evenly spread on the surface of the steel sheet cleaned with acetone and fixed, cured at 80°C for 30 minutes, and cured at 150°C for 1.5 hours. The bond strength was tested to be 11.3MPa, and the tensile modulus at the bond was 2840MPa.

[0049] Stir the resin, curing agent, and curin...

Embodiment 2

[0051] Using dichloromethyltetrasiloxane as raw material, it is directly added dropwise into p-phenylenediamine under stirring, the reaction temperature is controlled at 60-70°C, and the reaction time is 3h. After the reaction, the upper organic layer was separated and distilled under reduced pressure, and the fraction collected at 210-212° C. was the silicone epoxy resin curing agent represented by the above formula (2), with a yield of 94%.

[0052] Get 100 parts by weight of E-51 epoxy resin, 10 parts by weight of curing agent shown in formula (2), 0.4 parts by weight of triethanolamine, stir for 1.5-2 hours and mix evenly, according to GB-T7124-1986 (adhesive tensile shear strength Test method) Evenly spread on the surface of the steel sheet cleaned with acetone and fix it, cure at 80°C for 30 minutes, and cure at 150°C for 1.5 hours. The bond strength was tested to be 13.2MPa, and the tensile modulus at the bond was 2720MPa.

[0053] Stir the resin, curing agent, and cur...

Embodiment 3

[0055] Using dichloromethyldisiloxane as a raw material, it is directly added dropwise into ethylenediamine under stirring, the reaction temperature is controlled at 60-70°C, and the reaction time is 3h. After the reaction, the upper organic layer was separated and distilled under reduced pressure, and the fraction collected at 160-162° C. was the silicone epoxy resin curing agent shown in formula (3), with a yield of 96%.

[0056] Take 100 parts by weight of E-39 epoxy resin, 10 parts by weight of curing agent shown in formula (3), 0.3 parts by weight of 2-methyl-4-ethylimidazole, stir for 1.5-2 hours and mix well, according to GB-T7124- 1986 (Test Method for Tensile Shear Strength of Adhesives) Spread evenly on the surface of a steel sheet cleaned with acetone and fix it, cure at 80°C for 30 minutes, and cure at 150°C for 1.5 hours. Its bonding strength is tested to be 10.2MPa, and the tensile modulus of the bonded part is 2250MPa.

[0057] Stir the resin, curing agent, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com