Synergist and medium for fermentation culture of hairy mould

A technology of fermentation culture and synergist, applied in the direction of microorganism-based methods, microorganisms, fungi, etc., can solve the problems of long fermentation time, low metabolic rate, unstable products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

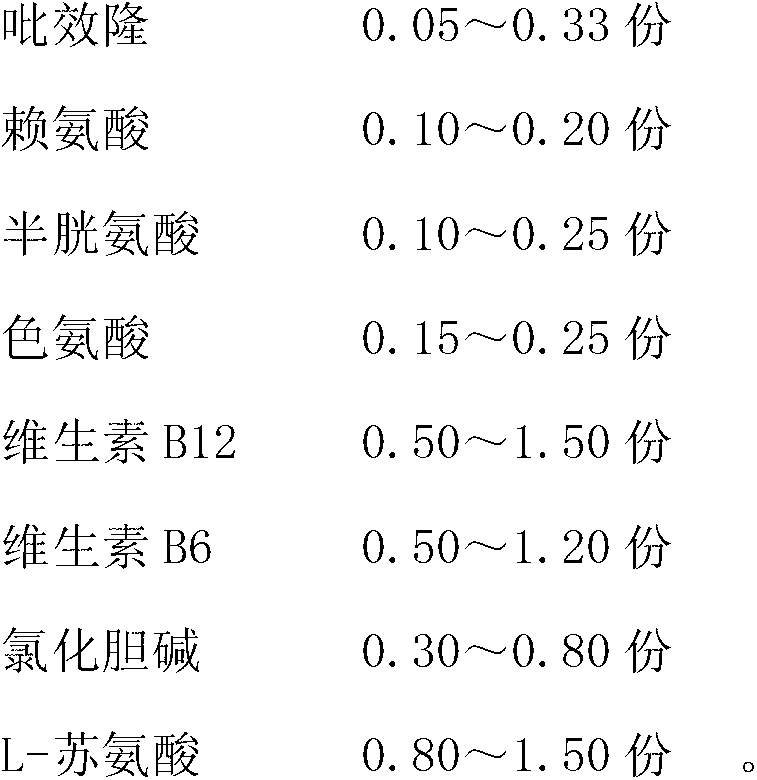

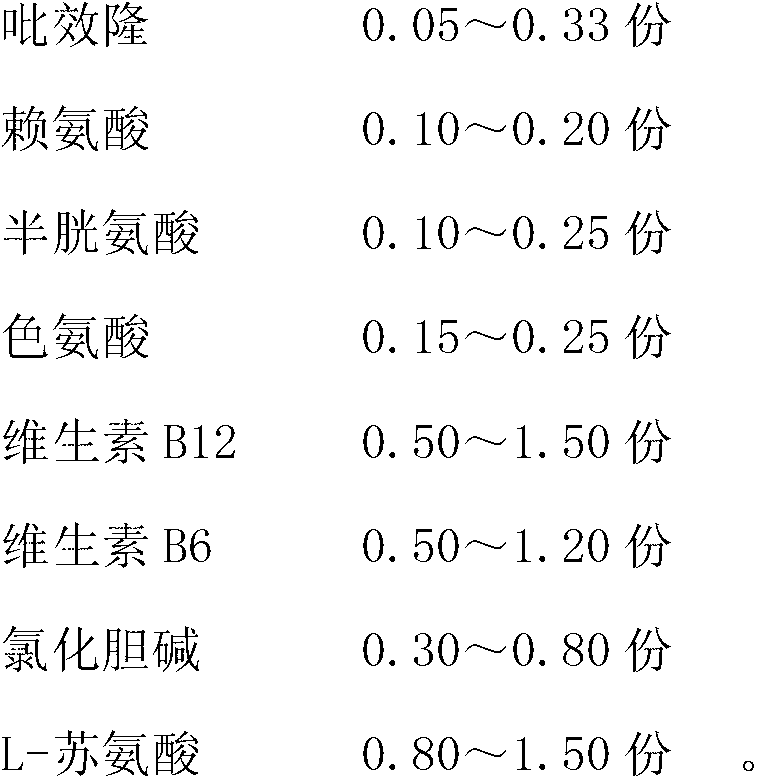

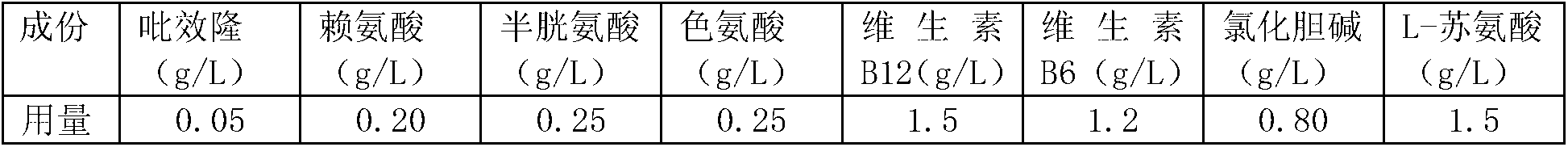

[0026]

[0027] Carry out the fermentation culture of Mucor:

[0028] 1. Prepare synergist and culture medium, then mix the two, the amount of synergist added is 1% of the total weight of the medium.

[0029] 2. The mucormycetes are selected from the mucormycetes, which are activated and inoculated into the culture medium. The culture temperature is 30 degrees Celsius, the culture time is 36 hours, and the song is turned every 4 hours.

[0030] 3. Purifying the fermentation broth in step 2, and performing an enzyme activity test on the separated product.

[0031] While performing steps 1-3, select the same mucormycetes to culture in the traditional medium for the same time, and the isolated product is also tested for enzyme activity.

Embodiment 2

[0033]

[0034] Carry out the fermentation culture of Mucor:

[0035] 1. Prepare synergist and medium, then mix the two, and the amount of synergist added is 0.75% of the total weight of the medium.

[0036] 2. Mucorus racemosa is selected for mucormycetes, and after activation, it is inoculated into the culture medium, the culture temperature is 40 degrees Celsius, the culture time is 36 hours, and the song is turned every 6 hours.

[0037] 3. Purifying the fermentation broth in step 2, and performing an enzyme activity test on the separated product.

[0038] While performing steps 1-3, select the same mucormycetes to culture in the traditional medium for the same time, and the isolated product is also tested for enzyme activity.

Embodiment 3

[0040]

[0041] Carry out the fermentation culture of Mucor:

[0042] 1. Prepare synergist and culture medium, then mix the two, the amount of synergist added is 0.5% of the total weight of the medium.

[0043] 2. The mucormycetes are selected from Mucor ruckeri, activated and inoculated into the culture medium, the culture temperature is 50 degrees Celsius, the culture time is 48 hours, and the song is turned every 5 hours.

[0044] 3. Purifying the fermentation broth in step 2, and performing an enzyme activity test on the separated product.

[0045] While performing steps 1-3, select the same mucormycetes to culture in the traditional medium for the same time, and the isolated product is also tested for enzyme activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com