Method for producing alkali protease from highland bacillus

A technology of bacillus uplander and protease, applied in the biological field, can solve the problems of unsatisfactory hydrolyzate, increased enzyme use cost, low unit enzyme activity, etc., and achieve the effects of simplified production technology, low production cost and fast fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

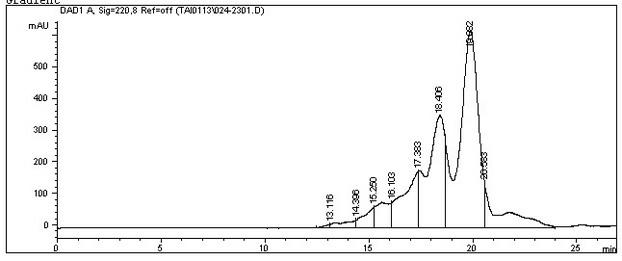

Image

Examples

Embodiment 1

[0018] A kind of method utilizing bacillus uplander to produce alkaline protease, specifically:

[0019] Select Bacillus uplander as the alkaline protease fermentation strain, and adopt the culture medium formula to contain: 50 grams of soybean meal, 50 grams of sucrose, 0.5 grams of Tween-80, 20 grams of glucose, and 0.7 grams of calcium chloride , Magnesium sulfate 0.4 grams, potassium chloride 0.3 grams. The fermentation conditions are as follows: the culture temperature is 37°C, the initial pH value is pH10.0, the stirring speed is 300 rpm, the aeration speed is 1vvm, and the fermentation time is 3 days. The fermented liquid is then filtered by a filter press, concentrated by ultrafiltration, added with stabilizers and preservatives, and packaged to obtain commercial alkaline protease.

Embodiment 2

[0021] A kind of method utilizing bacillus uplander to produce alkaline protease, specifically:

[0022] Select bacillus uplander to be the alkaline protease fermentation strain, and adopt the culture medium formula to contain: soybean meal 60 grams, sucrose 70 grams, Tween-80 0.7 grams, glucose 20 grams, calcium chloride 0. 7 grams, magnesium sulfate 0.4 grams, potassium chloride 0.3 grams. The fermentation conditions are as follows: the culture temperature is 37°C, the initial pH value is pH10.0, the stirring speed is 300 rpm, the aeration speed is 1vvm, and the fermentation time is 3 days. The fermented liquid is then filtered by a filter press, concentrated by ultrafiltration, added with stabilizers and preservatives, and packaged to obtain commercial alkaline protease.

Embodiment 3

[0024] A kind of method utilizing bacillus uplander to produce alkaline protease, specifically:

[0025] Select Bacillus uplander to be the alkaline protease fermentation strain, adopt the culture medium formula to contain: soybean meal 70 grams, sucrose 30 grams, Tween-80 0.4 grams, glucose 20 grams, calcium chloride 0. 7 grams, magnesium sulfate 0.4 grams, potassium chloride 0.3 grams. The fermentation conditions are as follows: the culture temperature is 37°C, the initial pH value is pH10.0, the stirring speed is 300 rpm, the aeration speed is 1vvm, and the fermentation time is 3 days. The fermented liquid is then filtered by a filter press, concentrated by ultrafiltration, added with stabilizers and preservatives, and packaged to obtain commercial alkaline protease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com