Exterior wall external insulation composite wall provided with support

A technology for external thermal insulation of external walls and composite walls is applied in the field of external thermal insulation composite walls of buildings, which can solve the problems of inconvenient construction, large quantity of prefabrication, large steel consumption, etc. The effect of low steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

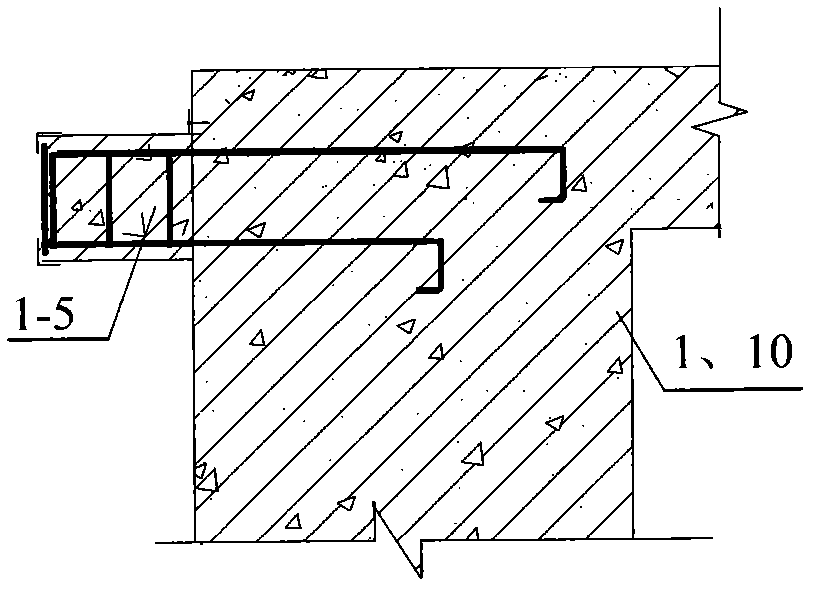

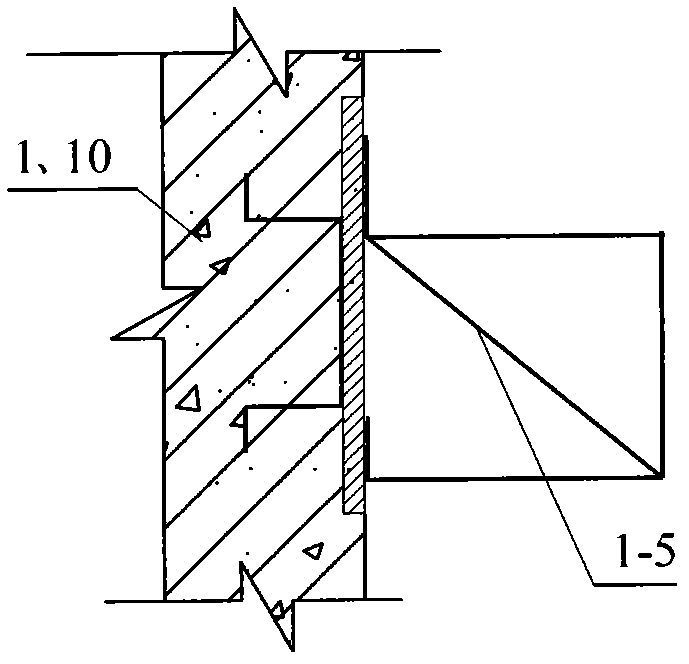

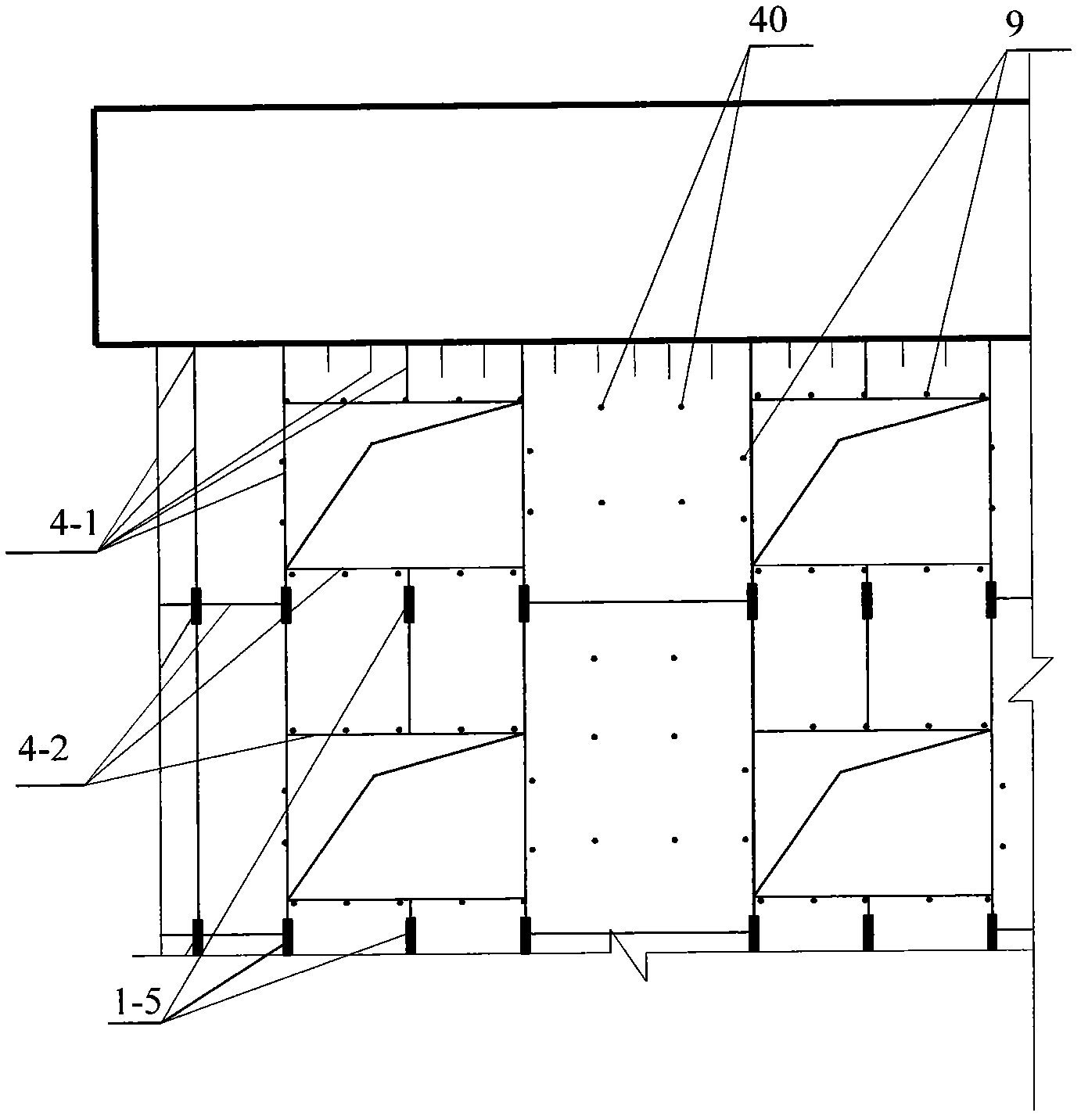

[0067] Embodiment one: see Figure 1 to Figure 8 , Figure 15, a kind of supporting external thermal insulation composite wall of the present embodiment is composed of base wall 1, steel truss cantilever beams 1-5, thermal insulation layer 3, mesh tensile material 5, steel bar 4, protective layer 8, It is composed of internally and externally connected steel wires 9 and a main building structure 10; the base wall 1 is a concrete wall, a load-bearing masonry wall, a non-load-bearing lightweight masonry filling wall or a wall made of steel and wood or bamboo and wood; the insulation layer 3 It is a polymer insulation material or a plant straw board or a paper honeycomb board or an inorganic insulation material; the steel bar 4 includes a vertical steel bar 4-1 and a horizontal steel bar 4-2; the mesh tensile material 5 is an alkali-resistant mesh cloth 5 -1 or metal mesh 5-2 or bamboo reinforcement mesh 5-3; the protective layer 8 is cement mortar or fine stone concrete, or mod...

Embodiment 2

[0078] Embodiment two: see Figure 9 The difference between the present embodiment and the first embodiment is that the reinforcing bars 4 of the present embodiment are parallel double reinforcing bars, and the parallel reinforcing bars 4 are connected with the outer ends of the steel truss cantilever beams 1-5, and between the parallel reinforcing bars 4, Set steel bars to form a small truss structure or set steel plates or partially welded block-shaped steel to form a reinforced structure with parallel double steel bars, which is a supported external thermal insulation composite wall.

[0079] When installing anti-theft fences and heavy decorations on doors and windows, it is necessary to install steel plates on the steel bars of doors and windows so as to connect iron parts and steel plates for fixing. Therefore, the doors and windows are equipped with double steel bars, and steel plates are installed at the required positions between the double steel bars, so that the anti...

Embodiment 3

[0080] Embodiment three: see Figure 9 The difference between this embodiment and embodiment one or two is that the present embodiment welds steel plates at the outer ends of steel truss cantilever beams 1-5, and installs the shaped steel keel for hanging objects on external walls such as decorative curtain walls, billboards or solar photovoltaic panels. Connect with steel truss cantilever beams 1-5 outer end steel plates or / and with steel plates or block shaped steel on parallel steel bars 4 to form a supported external wall external thermal insulation composite wall and install decorative curtain walls, billboards or The structure of external wall hangings such as solar photovoltaic panels.

[0081] This embodiment is to solve the fire prevention problem of the composite thermal insulation wall curtain wall described in the background technology. In the cavity between the decorative curtain wall and the protective layer, fire isolation belts should also be set at a certain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com