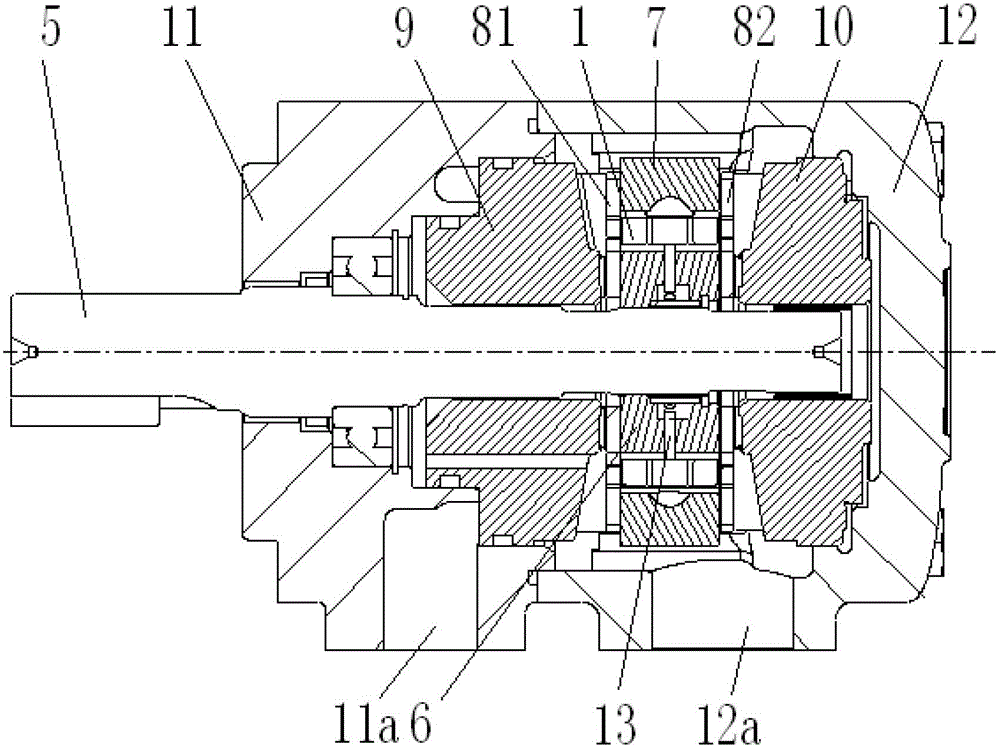

High-pressure anti-friction column pin type vane pump

A vane pump, grinding column technology, applied in the direction of rotary piston pump, pump, rotary piston/oscillating piston pump components, etc., can solve the surface wear of the vane and stator curve, the vane pump has poor wear reduction effect, and the vane pump Noise and other problems, to achieve the effect of simple structure, good wear reduction performance and large pump flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

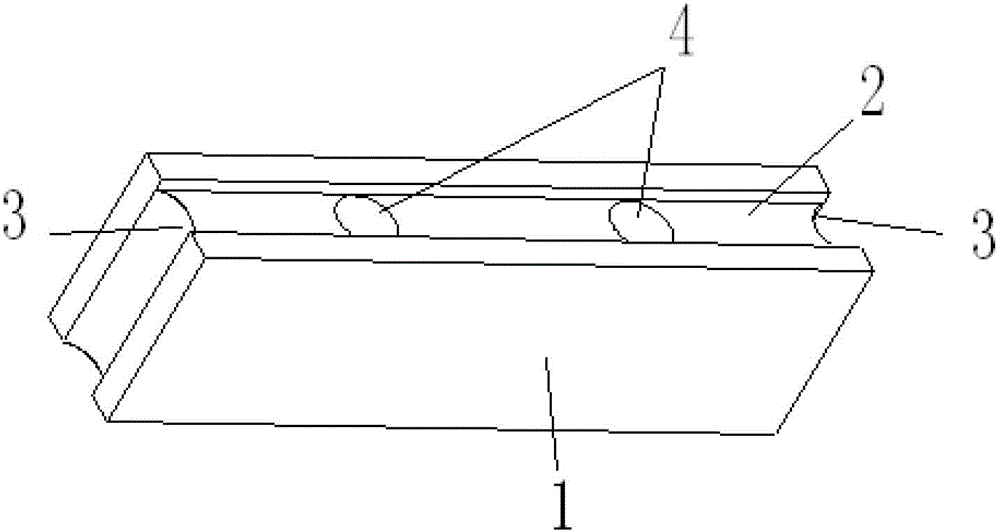

[0020] Such as Figure 2-5 As shown, the anti-friction blade of the present invention includes: a flat hexahedron blade 1; a first anti-friction oil groove 2 arranged on the top end surface of the blade 1; a second anti-friction oil groove 3 arranged on the left and right ends of the blade 1. Adopting the structure with anti-friction oil grooves on the three end surfaces, the hydraulic pressure of the anti-friction vane 1 and the oil distribution surface of the vane pump installed with the anti-friction vane 1 can be balanced during operation, and the anti-friction vane 1 can always be automatically Stable in the middle position where the friction force is the least, that is, the friction between the anti-friction blade 1 and the stator can be reduced; and a plurality of first pin holes 4 are arranged in the first anti-friction oil groove 2, adopting such a structure can make The pin passing through the pin hole bears against the wear-reducing vane 1, and makes the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com