Explosion-proof inspection hole lamp using LED (light-emitting diode) light source

A technology of LED light source and viewing hole, which is applied in the field of explosion-proof viewing hole lamps, can solve the problems of failing to meet explosion-proof requirements, not being able to correctly control the direction of light, and having no light distribution device, etc., to achieve dustproof, flammable, explosive and harmful gases Penetration, increase illuminance and light distribution accuracy, and improve the effect of explosion-proof grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

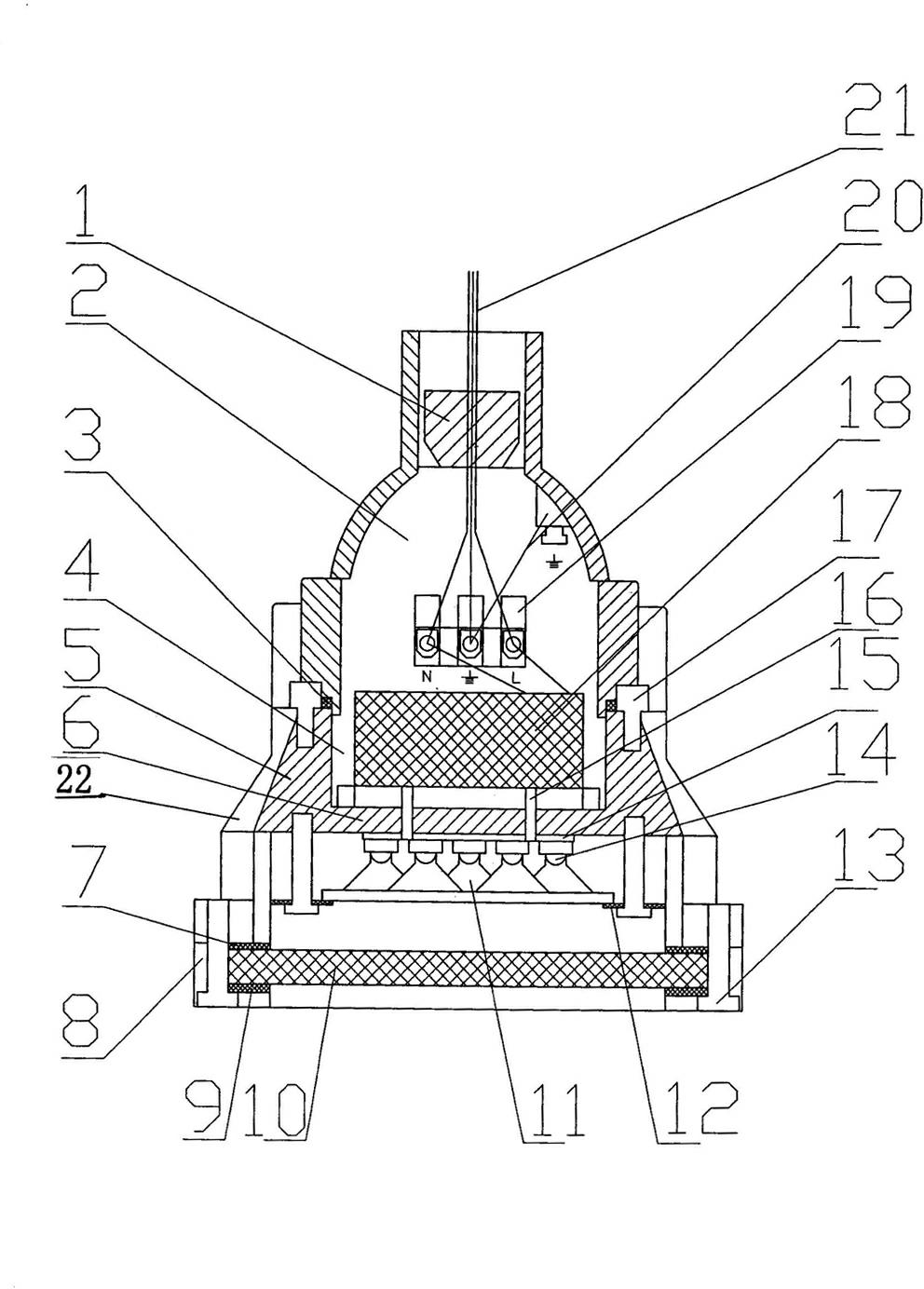

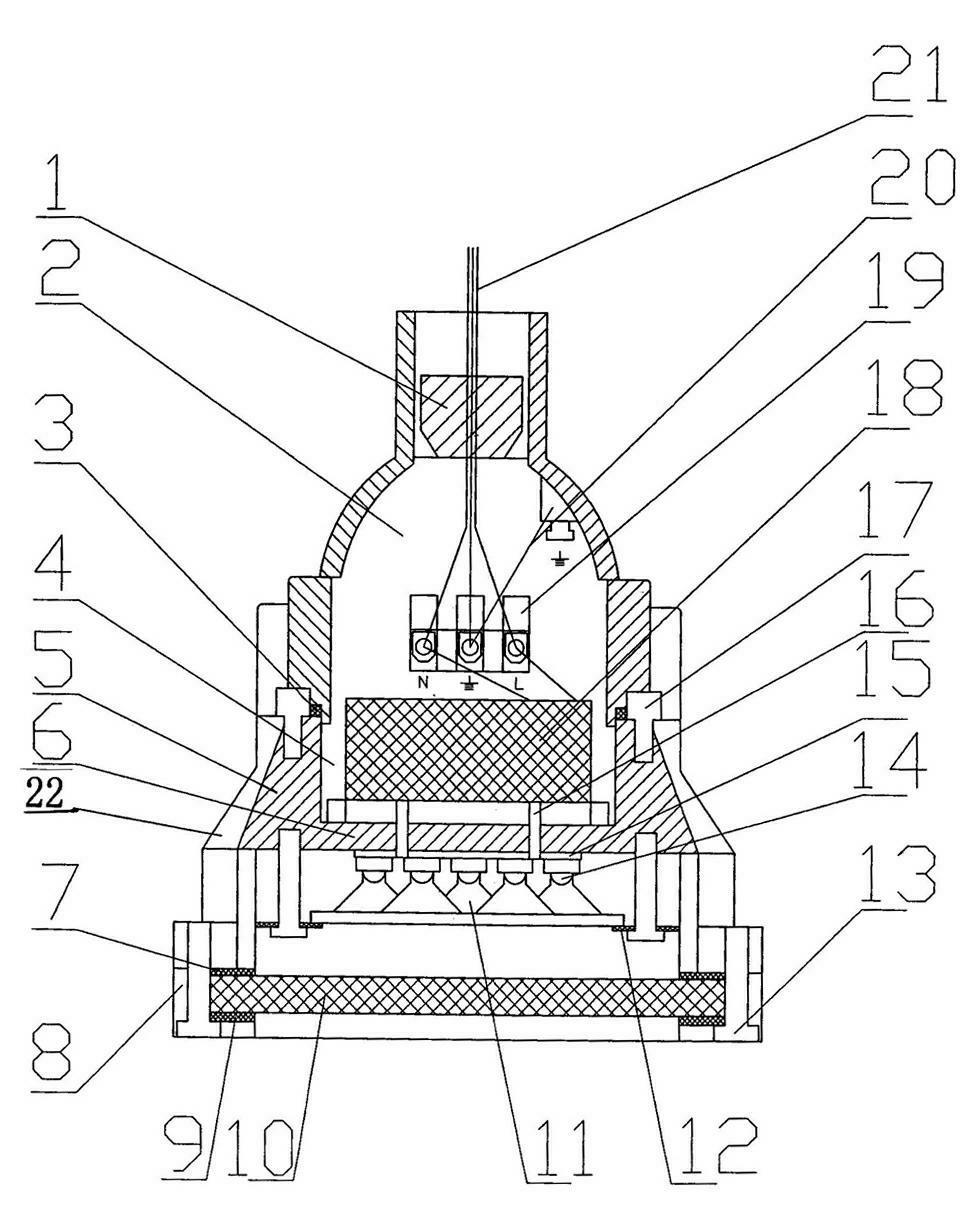

[0019] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail below in conjunction with the accompanying drawings in the form of embodiments, but none of the descriptions of the embodiments is a description of the present invention. Restriction of the technical solution of the invention, any equivalent transformation made according to the concept of the present invention which is only in form but not in substance shall be regarded as the scope of the technical solution of the present invention.

[0020] see figure 1 , The present invention relates to an explosion-proof sight hole lamp using LED light source, including a rubber seal 1, an upper end cover 2, a lamp body 5, a heat conducting plate 6, a lower end cover 8, an explosion-proof glass 10, a convex mirror 11, and a convex mirror pressure ring 12 , LED light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com