Device for simulating ground source heat pump

A technology of ground source heat pump and simulation device, which is applied in the direction of material thermal development to achieve the effect of complex and simplified geological structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

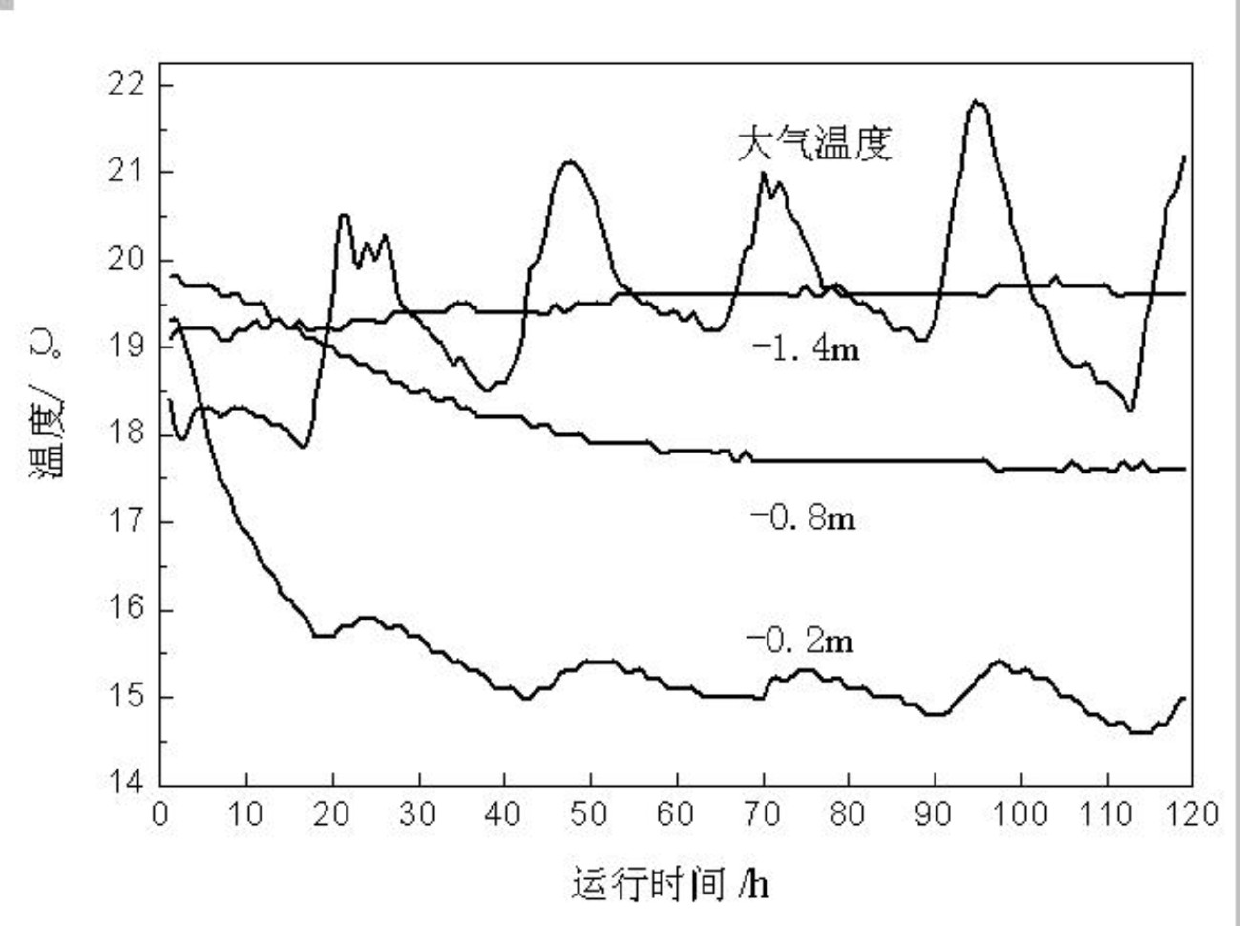

[0033] Refer to image 3 Using the present invention, under cooling conditions (the circulating water temperature is set to 0°C, and the flow rate is 3.3 L / min), the variation law of soil layer temperature at different depths with operating time is studied.

[0034] It can be seen from the figure that the surface soil (-0.2m) is most significantly affected by the heat exchange tubes and the outside world. The soil temperature drops sharply in the first 20 hours, and then changes little, and shows a phenomenon that fluctuates with atmospheric temperature fluctuations. . The figure shows that the temperature change of the surface soil lags behind the temperature change by 2 to 3 hours. As the soil depth increases, the drop in soil temperature decreases. After reaching the heat transfer equilibrium, the -0.8m temperature layer appears to be a stable state. For the bottom -1.4m soil, the average temperature is almost not affected by the heat exchange tube.

[0035] It can be seen th...

Embodiment 2

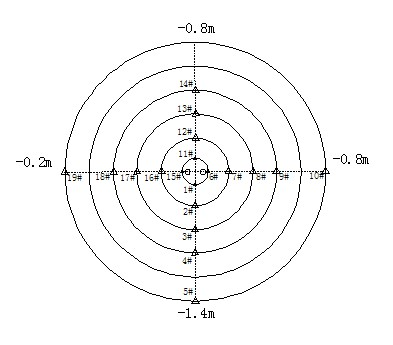

[0037] Refer to Figure 4 Using the present invention, under refrigerating conditions (the circulating water temperature is set to 0°C, and the flow rate is 3.3L / min), the variation law of different radial soil temperatures with operating time is studied.

[0038] The 0.195m soil layer in the radial direction closest to the heat exchange tube dropped sharply in the initial 20h, and later showed fluctuations and delays with the fluctuation of atmospheric temperature. The temperature of the middle two radial layers (0.335m, 0.470m) decreases slowly with the extension of running time, and tends to stabilize in the later stage. The 0.610m radial soil layer is the farthest away from the heat exchange tube, and with the effect of the polyurethane insulation material, it only shows its own heat storage and environment-dependent effects.

[0039] It can be seen that different radial soil layers have varying degrees of delay and attenuation with changes in atmospheric temperature; the close...

Embodiment 3

[0041] Using the present invention, under heating conditions (circulating water at 40°C, flow rate of 3.7L / min), run for 168h, and calculate the heat exchange model in the borehole according to the heat exchange results. The brief calculation process and results are as follows:

[0042] 1) One-dimensional heat conduction model in the borehole:

[0043] Thermal resistance term Calculated value (K·m / W) The proportion Thermal resistance from fluid to PE pipe0.013 7.39% PE pipe thermal resistance0.054 31.75% Grout thermal resistance0.104 60.86%

[0044] The thermal resistance calculation results of each part are shown in the table above. The total thermal resistance in the borehole is the sum of the three, which is 0.170 K·m / W. The thermal resistance of the grouting material accounts for the main part of the thermal resistance in the borehole, which also proves the importance of studying grouting materials. Estimate the borehole wall temperature T according to the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com