Miniature gas chromatographic column integrated chip with rapid separation function

A micro-gas chromatography and integrated chip technology, which is applied in the field of micro-gas chromatographic column integrated chips, can solve the problems of insensitivity to temperature response, affecting the separation performance of the chromatographic column, and low heating temperature, so as to improve the separation speed and performance, Effect of Rapid Separation Overall Separation Performance, Rapid Temperature Separation Speed, and Separation Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

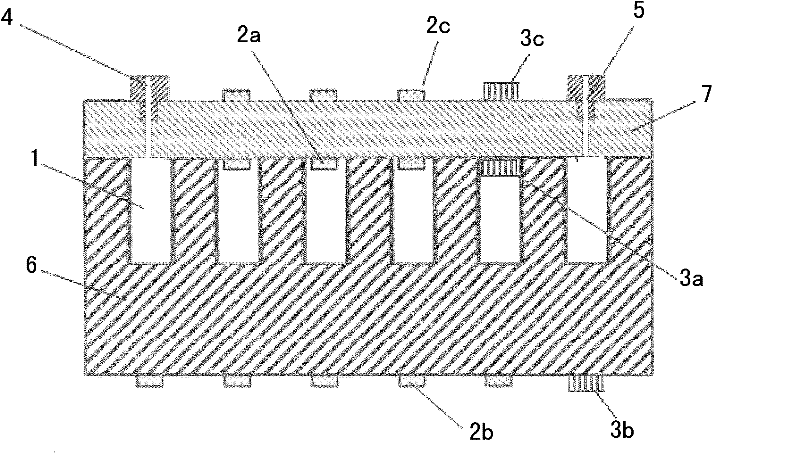

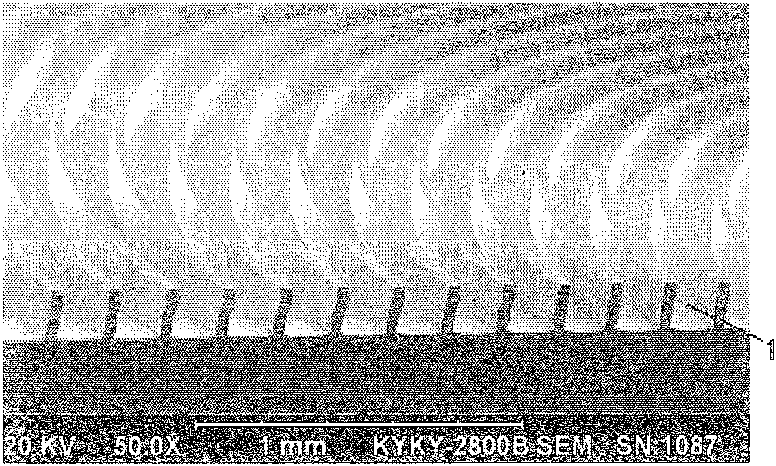

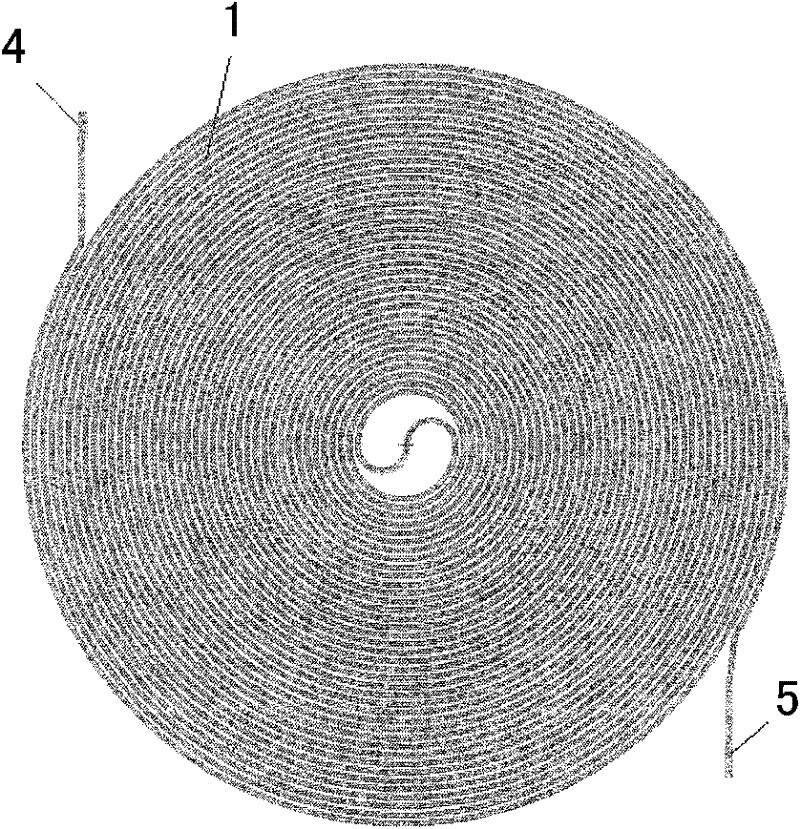

[0044] To clean N-type or P-type double-sided polished single crystal silicon wafers, first deposit a layer of 2000 on the silicon substrate 6 Aluminum (aluminum thickness range can be in 1000 -7000 Select) film, then positive resist AZ1500 photolithography and wet etching to remove aluminum, expose the chromatographic channel, and then use deep etching technology to etch to obtain the channel of the micro-chromatographic column, (channel width can be 100-300 microns, length 0.5-6 meters, the depth is 50-150 microns to choose), and then use H 3 PO 4 The mask (aluminum) is removed by wet etching, and the channel 1 of the micro-chromatographic column is obtained after cleaning and drying the channel of the micro-chromatographic column.

Embodiment approach 2

[0046] Clean N-type or P-type double-sided polished single-crystal silicon wafers; first, grow a layer of 4000 by LPCVD or PECVD on the silicon substrate 6 Silicon nitride (the thickness of silicon nitride can be 2000-7000 Select) as insulating layer and mask, then positive resist AZ1500 photolithography, then reactive ion etching to remove silicon nitride, expose the channel of the micro-column, and then use KOH buffer chemical etching to obtain the channel of the micro-column ( The channel width can be selected from 100-300 microns, the length is 0.5-6 meters, and the depth is 50-150 microns). Finally, the channel 1 of the micro-chromatographic column is obtained after cleaning and drying the channel of the micro-chromatographic column.

[0047] The preparation process of the combined micro heater:

[0048] Embodiment of the preparation process of the first micro heater 2a:

[0049] With glass as the substrate 7, firstly, a layer of AZ1500 positive photoresist is coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com