Complementary metal oxide semiconductor (CMOS) image sensor and manufacturing method thereof

A technology of image sensor and manufacturing method, which is applied in radiation control devices and other directions, can solve problems such as crosstalk of CMOS image sensors, and achieve the effect of avoiding crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

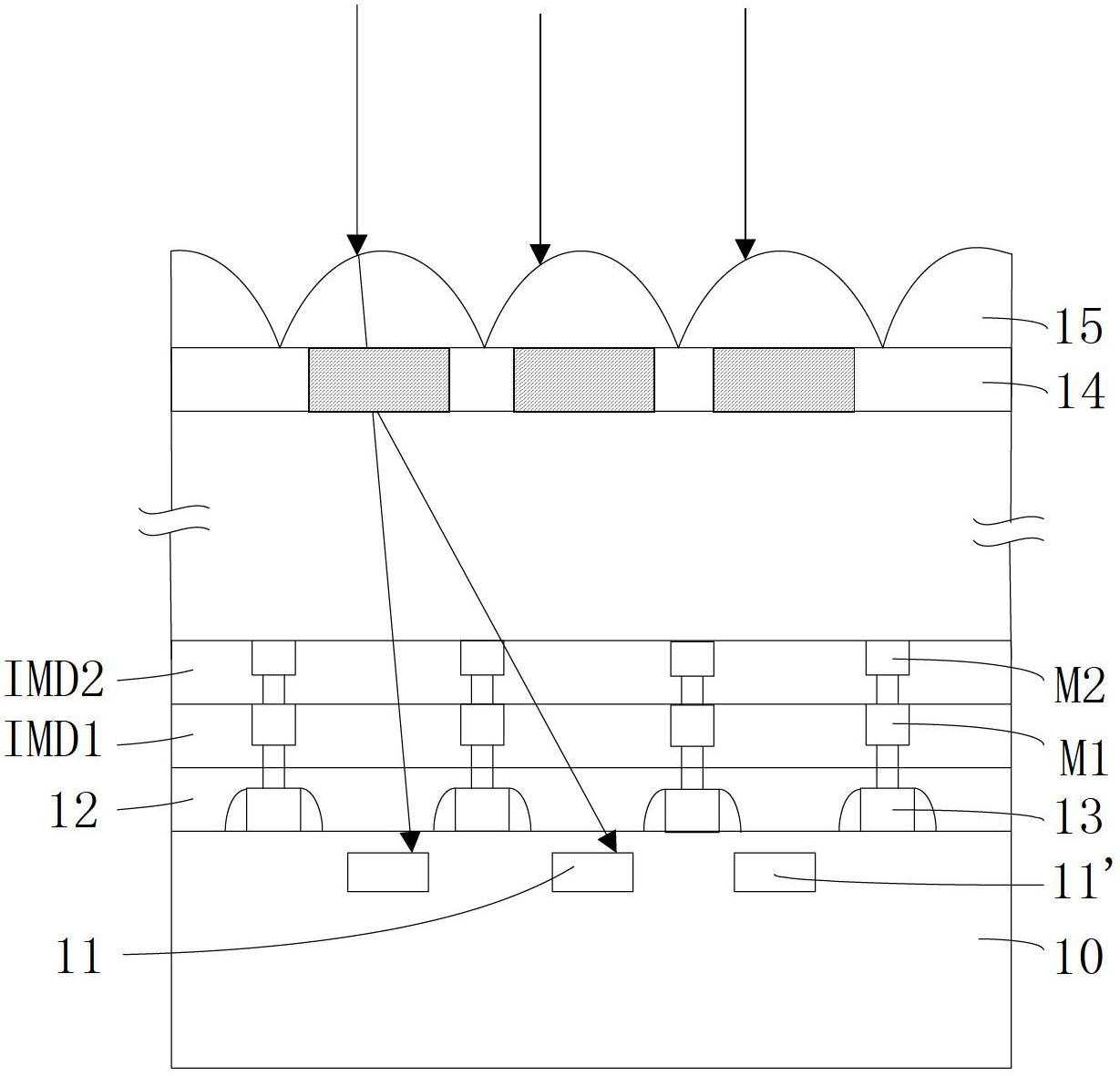

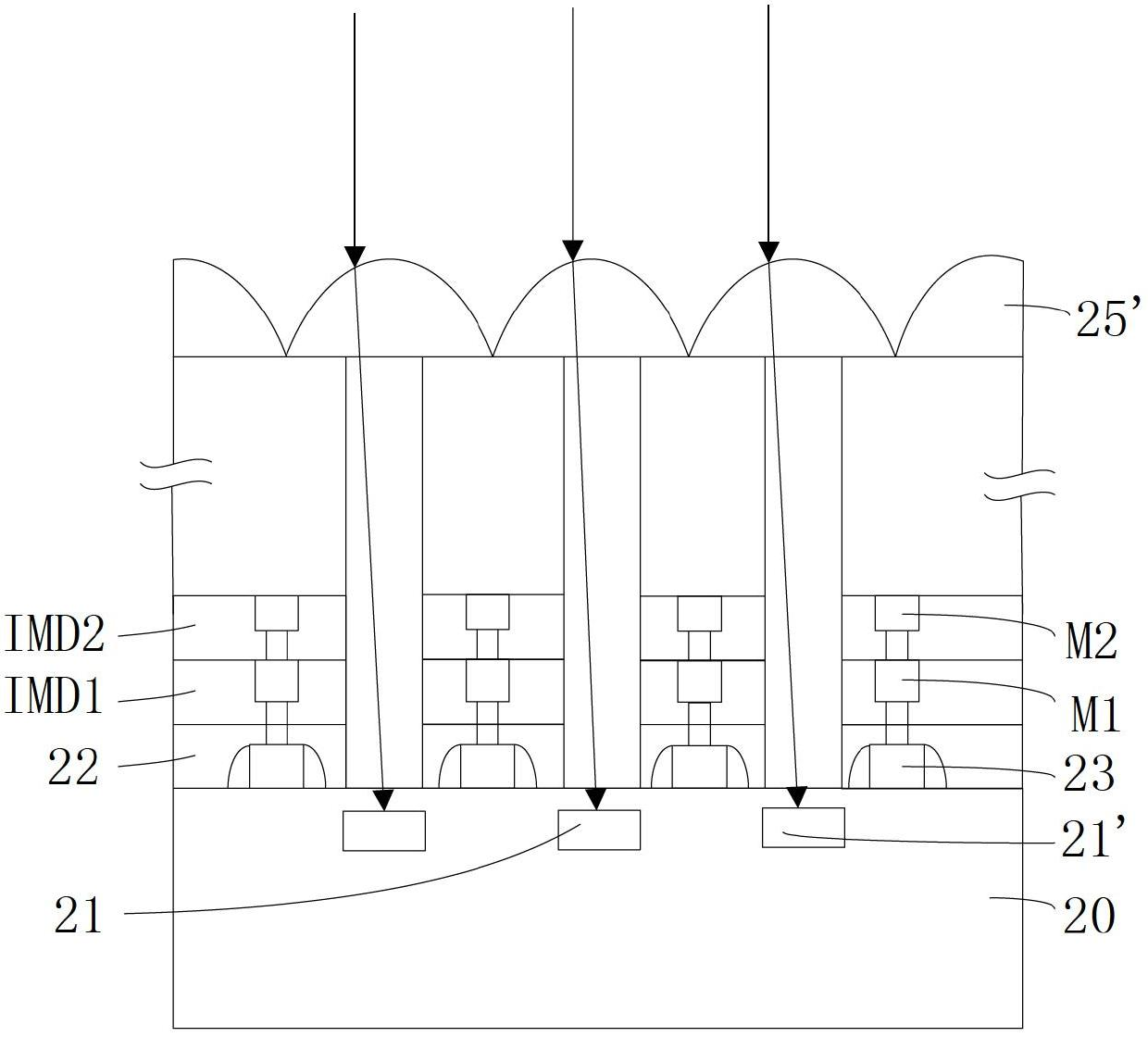

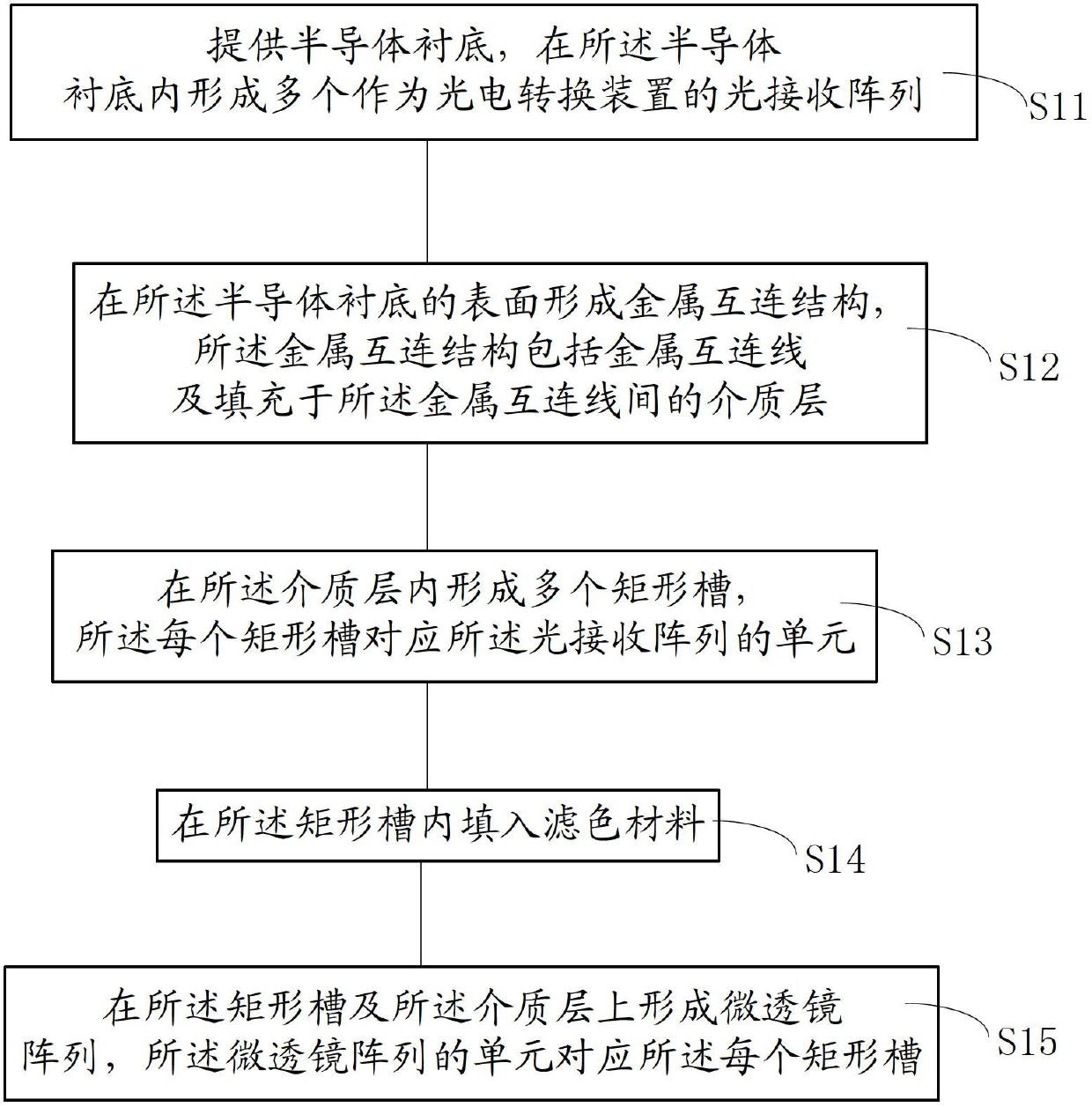

[0044] The following combination figure 2 The CMOS image sensor shown and image 3 The flow chart of the manufacturing method of the image sensor is shown, and the CMOS image sensor provided in the first embodiment and the mechanism for solving the crosstalk problem are introduced in detail.

[0045] First introduce the production method. combine image 3 and figure 2 As shown, step S11 is executed to provide a semiconductor substrate 20 in which a light-receiving array serving as a photoelectric conversion device is formed.

[0046] The material of the semiconductor substrate 20 in this embodiment may be silicon, germanium, silicon-germanium, etc., but is not limited to the above materials. The light-receiving array is an array formed by existing photosensitive elements as units, for example, more photodiodes 21, 21' are used, and its core structure is a PN junction. Compared with ordinary diodes, the difference in structure is: in order to receive When the incident li...

Embodiment 2

[0063] It can be seen that, in the first embodiment, since the shape of the groove is rectangular, the units of the color filter array are also rectangular. The inventor found in practice that adopting a groove with a small wedge-shaped structure at the bottom, such as Figure 8 As shown in , compared with the rectangular color filter unit, the formed color filter unit has a better capability of restricting the light propagating therein, thus improving the crosstalk effect better.

[0064] Correspondingly, the manufacturing method of the CMOS image sensor in this step is roughly the same as that in the first embodiment. The difference is that the new step S13' is: forming a plurality of wedge-shaped grooves in the dielectric layer, and the smaller bottom of each wedge-shaped groove corresponds to each unit of the light-receiving array.

[0065] The area of the dielectric layer in this step is the same as that in the first embodiment, and there are many ways to form the wedg...

Embodiment 3

[0067] In the CMOS image sensor of the third embodiment, on the basis of the CMOS image sensors provided in the first and second embodiments, a reflective layer is added on the side wall of the groove, so as to further limit the propagation of light in the color filter unit. Taking the wedge-shaped groove as an example, the cross-sectional schematic diagram of the CMOS image sensor including the reflective layer 26 is as follows: Figure 9 shown.

[0068] Specifically, the side wall of the reflective layer is made of aluminum, and may also be made of other materials that can realize the reflective function.

[0069] Correspondingly, the manufacturing method of the CMOS image sensor in this step is roughly the same as that in the first embodiment. The difference is that the new step S13" is: forming a plurality of rectangular or wedge-shaped grooves in the dielectric layer, and when the grooves are wedge-shaped, the smaller bottom of each wedge-shaped corresponding to each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com