Organic electroluminescent device and preparation method of organic electroluminescent device

An electroluminescent device and luminescent technology, applied in the field of electric light sources, can solve the problems of OLED luminous efficiency, low luminous intensity, luminous efficiency and color coordinate deviation, etc., to achieve improved luminous efficiency and luminous brightness, and stable luminous performance , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

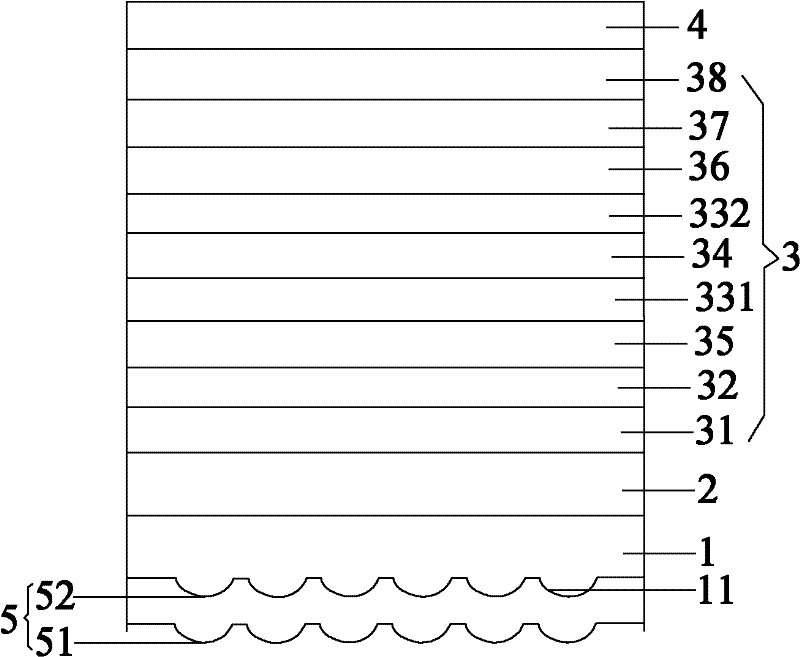

[0040] The embodiment of the present invention also provides the preparation method of the above-mentioned organic electroluminescent device, the process flow chart of the method is as follows Figure 4 shown, see also figure 1 or figure 2 or image 3 , the method includes the following steps:

[0041] S1. Provide a transparent substrate with opposite first surface and second surface, form convex lens-type protrusions 11 distributed in an array on the first surface of the transparent substrate, and prepare a transparent substrate 1; wherein, the first surface of the transparent substrate constitutes The first surface of the light-transmitting substrate 1, and the second surface of the transparent substrate are both the second surface of the light-transmitting substrate 1;

[0042] S2. Plating an anode layer 2 on the second surface of the light-transmitting base layer 1;

[0043] S3. Coating an organic electroluminescent structure 3 on the surface of the anode layer 2 oppo...

Embodiment 1

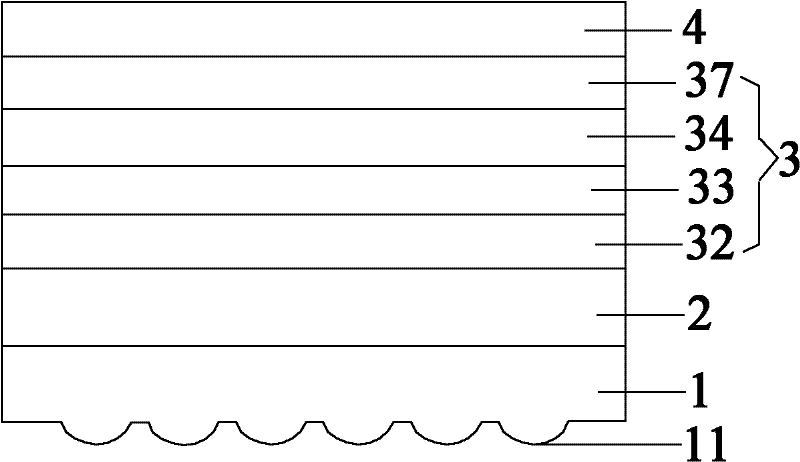

[0057] The structure of the organic electroluminescent device of this embodiment is as follows figure 1 As shown, the organic electroluminescent device includes a light-transmitting base layer 1, an anode layer 2, a hole transport layer 32, a light emitting layer 33, an exciton balance layer 34, an electron transport layer 37 and a cathode layer 4 which are sequentially stacked. Wherein, the light-transmitting base layer 1 has a first surface and a second surface opposite to each other, the first surface is provided with convex lens-shaped protrusions 11 distributed in an array, and the second surface is superposed with the anode layer 2 . The hole transport layer 32 , the light emitting layer 33 , the exciton balancing layer 34 , and the electron transport layer 37 constitute the organic electroluminescent structure 3 .

[0058] The diameter of the convex lens-shaped convex portion provided on the first surface of the light-transmitting base layer 1 is 20 μm, and the focal le...

Embodiment 2

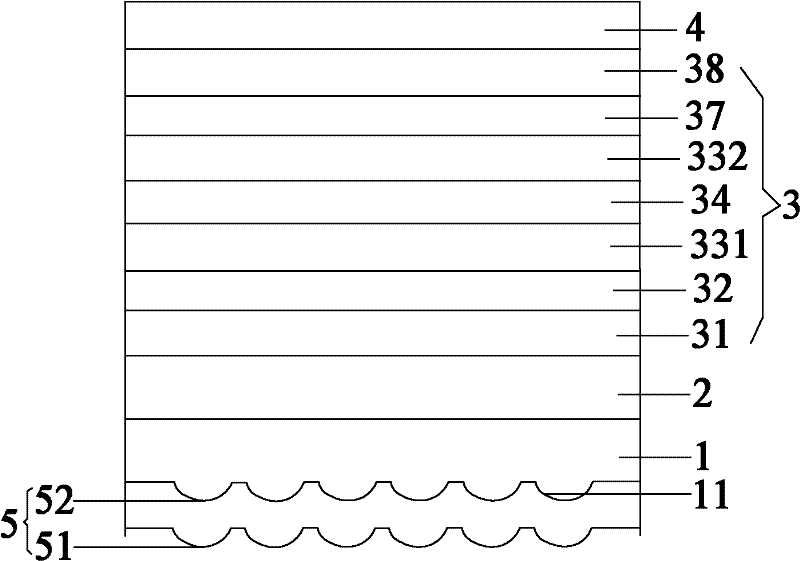

[0068] The structure of the organic electroluminescent device of this embodiment is as follows figure 2 As shown, the organic electroluminescent device includes a light-enhancing film layer 5, a light-transmitting base layer 1, an anode layer 2, a hole injection layer 31, a hole transport layer 32, a red light-emitting layer 331, and an exciton balance layer stacked in sequence. layer 34 , green light emitting layer 332 , electron transport layer 37 , electron injection layer 38 and cathode layer 4 . Wherein, one surface of the light enhancing film layer 5 is provided with concave lens-shaped concave portions 52 distributed in an array, and the other surface opposite to the surface provided with the concave portions 52 is provided with convex lens-shaped convex portions 51 distributed in an array. The surface of the organic electroluminescent device of this embodiment is used as the light-emitting surface of the organic electroluminescent device; the light-transmitting base l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com