Method for recovering mesoporous molecular sieve organic template

A technology of organic templates and mesoporous molecular sieves, applied in solid solvent extraction, etc., can solve problems such as no relevant literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

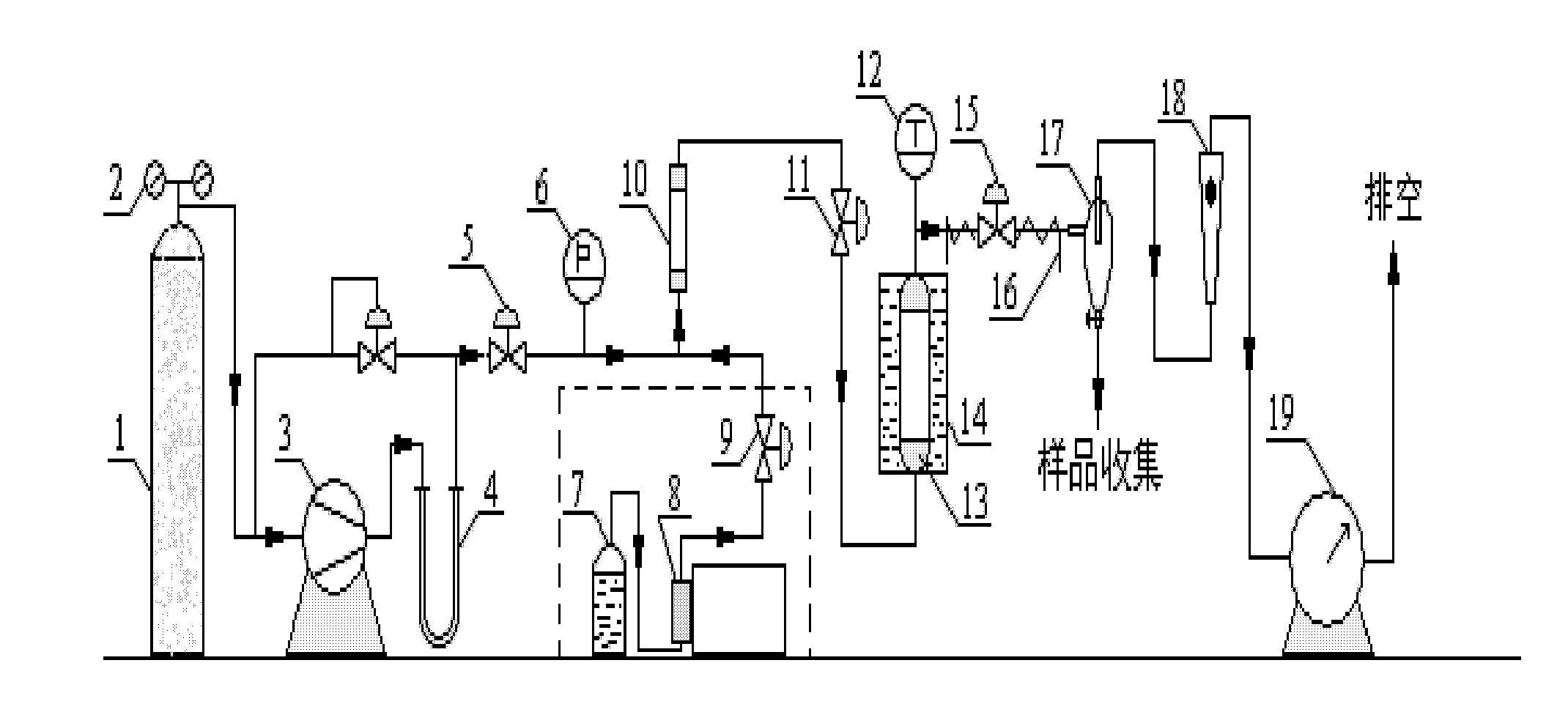

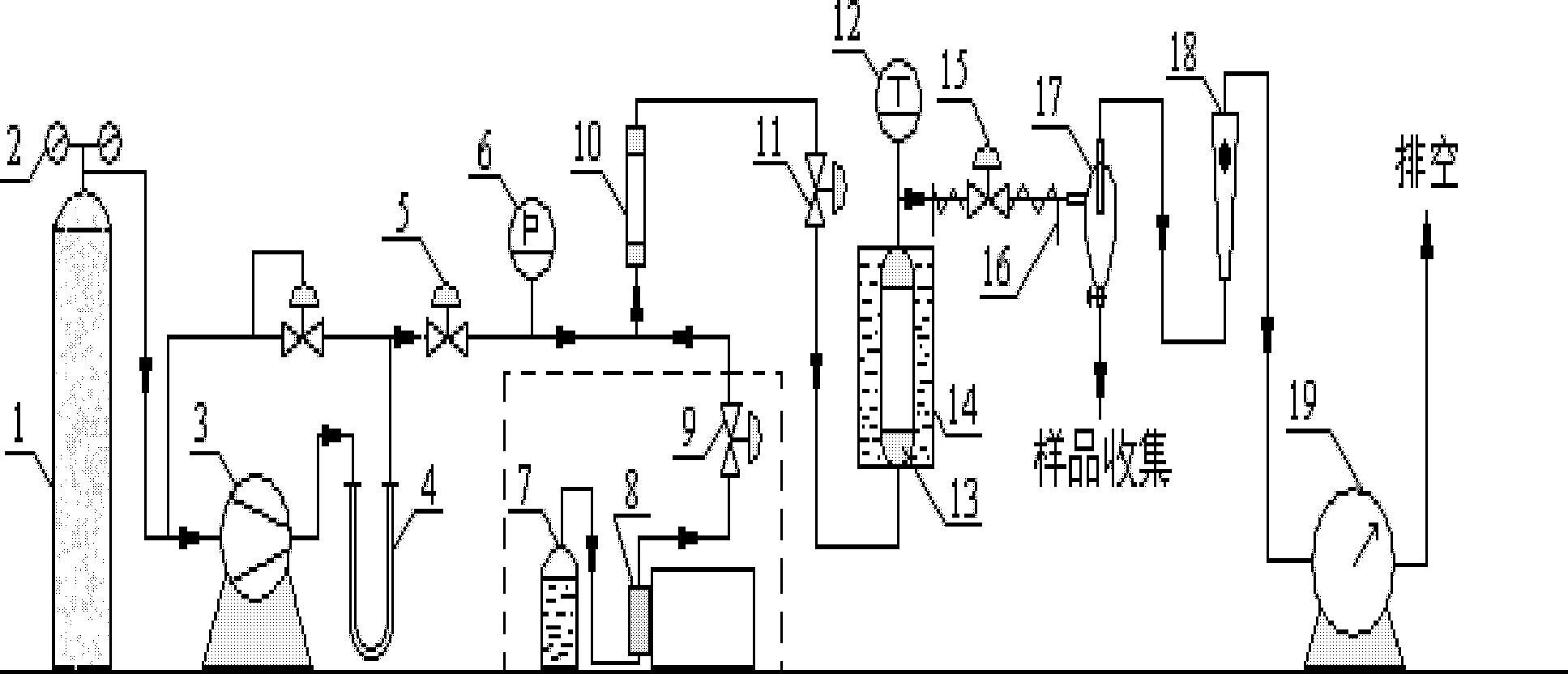

Method used

Image

Examples

Embodiment 1

[0019] The raw material is the mesoporous molecular sieve obtained by assembling the precursor of the Y-type molecular sieve by using P123, wherein the content of the template agent is 30-45%. Weigh 10 g of raw material and add it to the extractor, supercritical CO 2 After fully mixing with the entrainer n-hexane, it is added into the extractor from the bottom of the extractor. Control the pressure of the extractor at 25±2MPa, the temperature at 40±3°C, supercritical CO 2 The flow rate is 40L / h, the extraction time is 2.5h, the molar ratio of entrainer n-hexane is 0.035, and the recovery rate of template agent is about 72%.

Embodiment 2

[0021] The raw material is the mesoporous molecular sieve obtained by assembling the precursor of the ZSM-5 molecular sieve with P123, wherein the content of the template agent is 30-45%. Take by weighing 35g of raw material and add in the extractor, entrainer acetone and supercritical CO 2 After mixing well, add to the extractor from the bottom of the extractor. Control the pressure of the extractor at 13.5±2MPa and the temperature at 65±2°C. Static extraction was carried out for 2 hours first, and the molar ratio of entrainer acetone was 0.05. Reconditioning supercritical CO 2 The flow rate is 45L / h, the dynamic extraction time is 2.5h, and the recovery rate of template agent is about 81%.

Embodiment 3

[0023] The raw material is the mesoporous molecular sieve obtained by assembling the precursor of the BETA molecular sieve by using P123, wherein the content of the template agent is 30-45%. Weigh raw material 9.9g and add in the extractor, entrainer ethyl ester and supercritical CO 2 After mixing well, add to the extractor from the bottom of the extractor. Control the pressure of the extractor to 20±2MPa, the temperature to 65±2°C, the molar fraction of entrainer ethyl ester to be 0.10, supercritical CO 2 The flow rate is 50L / h, and the extraction time is 4h. The recovery rate of the templating agent was about 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com